A kind of method for preparing polyphenylene sulfide inorganic particle composite material

A technology of polyphenylene sulfide and inorganic particles, which is applied in the field of preparation of composite materials, can solve problems such as uneven dispersion, affecting the mechanical and thermal properties of composite materials, and achieve the effect of improving mechanical properties and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 200 grams of low-melting glass with a softening temperature of 325°C and polyphenylene sulfide with a melting point of 280°C and a decomposition temperature greater than 450°C [density ρ=1.35g / cm 3, melt index MI=297g / 10min (5kg, 315°C, 2.09mm, GB / T 3682-2000)] 800g mixed and placed in a 120°C oven to dry for 4h, then taken out, put into a planetary ball mill and mixed for 20min, The rotating speed of the ball mill is 400r / min to obtain the premixed powder. Put the premixed powder into an internal mixer, knead for 8 minutes at a temperature of 400°C and a speed of 80 r / min, take it out, and mold it into a sample for testing.

Embodiment 2

[0041] Take 600 grams of low-melting glass with a softening temperature of 325°C and 400 grams of polyphenylene sulfide with a melting point of 280°C and a decomposition temperature greater than 450°C, mix them together and place them in an oven at 120°C to dry for 4 hours. After taking them out, put them in a planetary Mix in a ball mill for 20 minutes at a speed of 400 r / min to obtain premixed powder. Put the premixed powder into an internal mixer, knead for 10 minutes at a temperature of 400°C and a speed of 80 r / min, take it out, and mold it into a sample.

Embodiment 3

[0047] Take 600 grams of low-melting point glass with a softening temperature of 350°C and 400 grams of polyphenylene sulfide with a melting point of 280°C and a decomposition temperature greater than 450°C, mix them together and place them in an oven at 120°C for 4 hours. After taking them out, put them in a planetary Mix in a ball mill for 20 minutes at a speed of 400 r / min to obtain premixed powder. Put the premixed powder into an internal mixer, knead for 10 minutes at a temperature of 400°C and a speed of 80 r / min, take it out, and mold it into a sample.

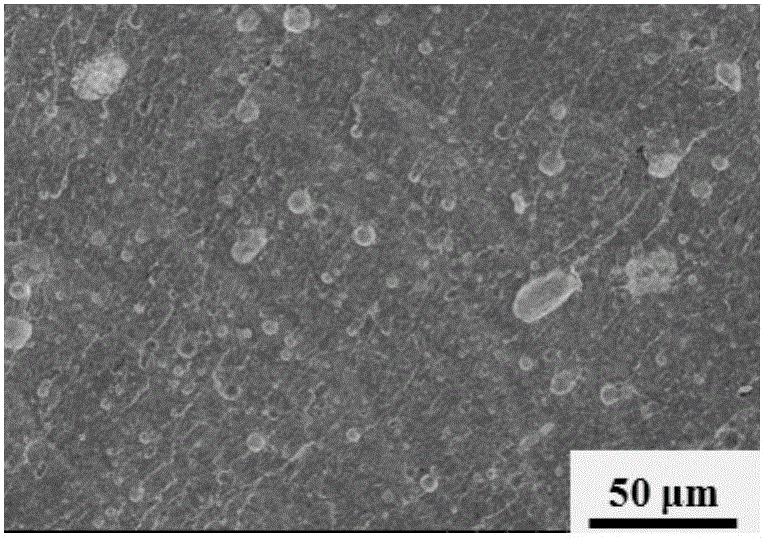

[0048] Figure 5 It is the scanning electron micrograph of the polyphenylene sulfide inorganic particle composite material prepared in embodiment 3, observe Figure 5 , the low-melting-point glass in the composite material presents a regular spherical shape in the matrix. After testing, its average particle size is 6.6 μm, and its particle size distribution is wider than that of the low-melting-point glass with a softe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com