Grout sleeve for connecting prefabricated member steel bars and construction method of grout sleeve

A technology for prefabricated components and grouting sleeves, which is applied to building components, structural elements, building reinforcements, etc., can solve the problems of complex construction process, difficult to guarantee the quality of steel bar connection, and inability to connect steel bars, and achieves low cost, simple construction, The effect of reliable connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

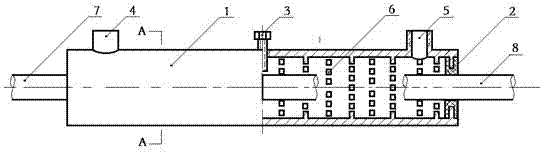

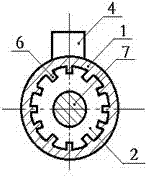

Embodiment 1

[0010] The sleeve body 1 of the present invention can be made by casting. In order to remove the mold smoothly, the wall thickness of the middle part of the sleeve body 1 can be greater than that of the two ends, which is more in line with the distribution rule that the internal force in the middle part of the sleeve body is large and the internal force at both ends is small. The independent cubic block-shaped protrusion 6 provided on the inner wall of the sleeve ensures the bonding effect between the steel bars 7 and 8, the grouting material and the sleeve body 1. After the grouting material is solidified and hardened, the two reserved steel bars are connected through the sleeve to form a One. The outer diameter of the elastic rubber sealing ring 2 at both ends of the sleeve body 1 is greater than the inner diameter of the sleeve body 1, and the inner diameter of the elastic rubber sealing ring 2 is slightly smaller than the outer diameter of the steel bars 7 and 8 to ensure t...

Embodiment 2

[0012] The construction method of the present invention is as follows. After the assembled prefabricated components are manufactured in the factory, the reserved steel bars 7 can be temporarily inserted into the sleeve body 1 and fixed with the fixing bolts 3 to prevent the sleeve from being lost. During assembly and construction, loosen the fixing bolts 3 and remove the sleeve. For cylinder body 1, first put two elastic sealing rubber rings 2 on the reserved steel bars 7 and 8 respectively, insert the reserved steel bars 7 and 8 of the two assembled prefabricated components from both ends of the sleeve body 1, hoist and position them, Move the sleeve body 1 to the joint of the steel bars, adjust to the design depth of the two coaxial steel bars, screw in the fixing bolt 3 to fix it, squeeze in the elastic sealing rubber ring 2, connect the grouting gun to the grouting hole 4 through threads, and pour in cement Base grouting material, the air vent 5 should be unblocked during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com