Chimney sliding lifting platform construction method and construction device

A technology of construction device and chimney, applied in the direction of formwork/template/work frame, house structure support, house structure support, etc., can solve the problems of waste of resources, poor positioning accuracy of internal and external molds, unfavorable construction, etc., to save engineering costs, The effect of high safety and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] The present invention will be described in detail below with reference to the drawings and embodiments:

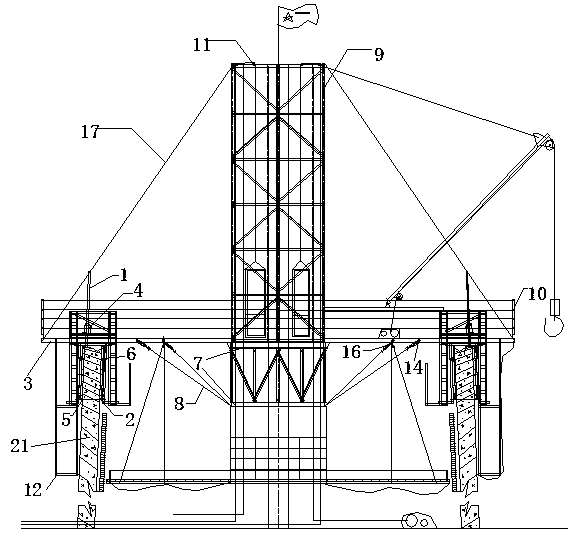

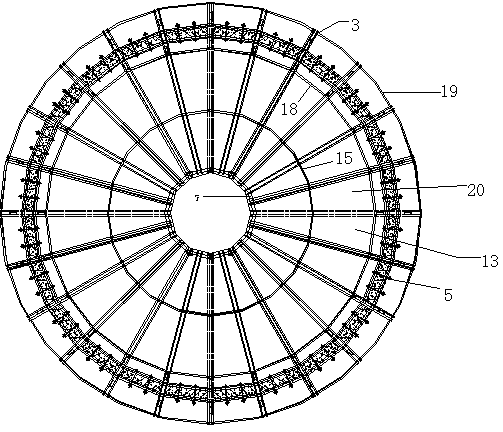

[0042] Attached Figure 1 to 4 It can be seen that a construction method of a chimney sliding platform includes the following steps:

[0043] Install the inner drum ring on the chimney cup; the first outer drum ring 15, the second outer drum ring 18 and the third outer drum ring 19 are arranged on the outer side of the inner drum ring 7 in sequence;

[0044] Install the radiation beam 3; the radiation beam 3 is arranged radially on the upper surface of the inner drum ring 7 and the first outer drum ring 15, the second outer drum ring 18 and the third outer drum ring 19; the radiation beam 3 is connected to the inner drum by bolts Ring 7, the first outer drum ring 15, the second outer drum ring 18 and the third outer drum ring 19 are connected; the radiation beam 3 is composed of two channel steels;

[0045] Install the derrick 9; the derrick 9 and the inner drum ring 7 are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap