Floating side plate for high-pressure large-displacement gear pump

A floating side plate, large displacement technology, applied in pump components, machines/engines, rotary piston type/oscillating piston type pump components, etc. Unbalance and other problems, to achieve the effect of improving the stress condition, the symmetrical flow field distribution, and the improvement of the pressure gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

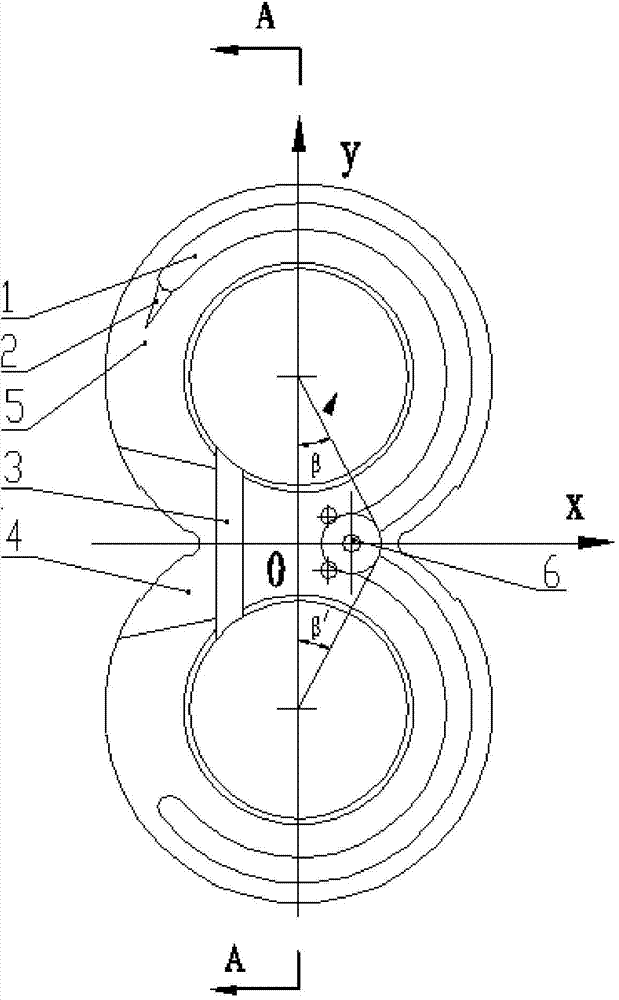

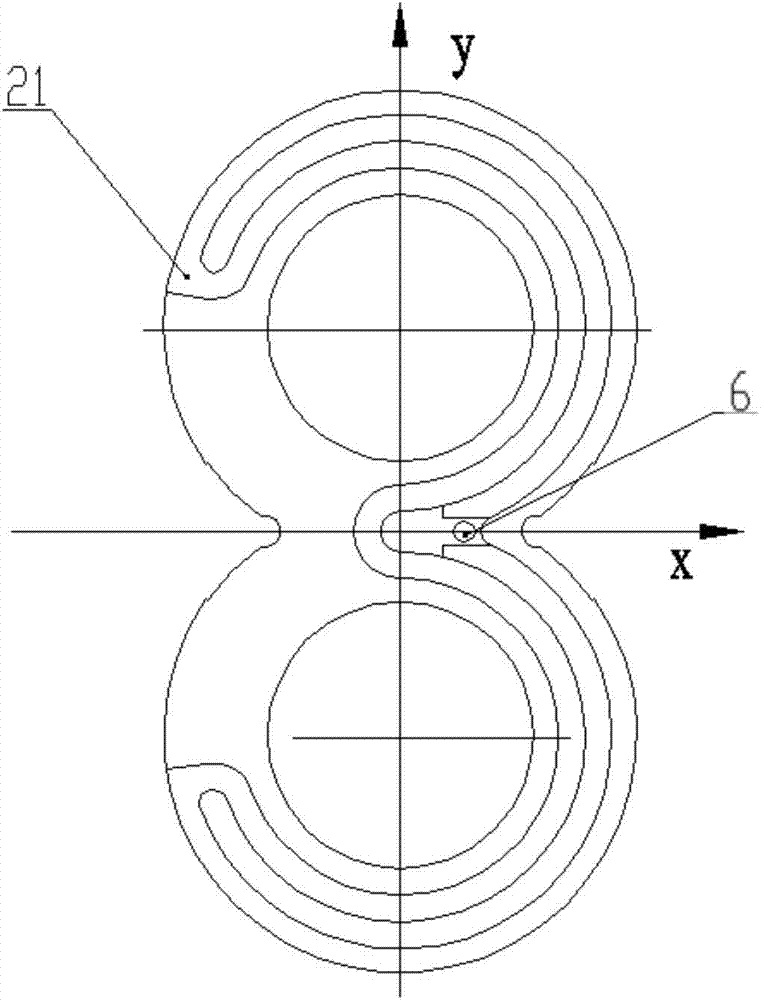

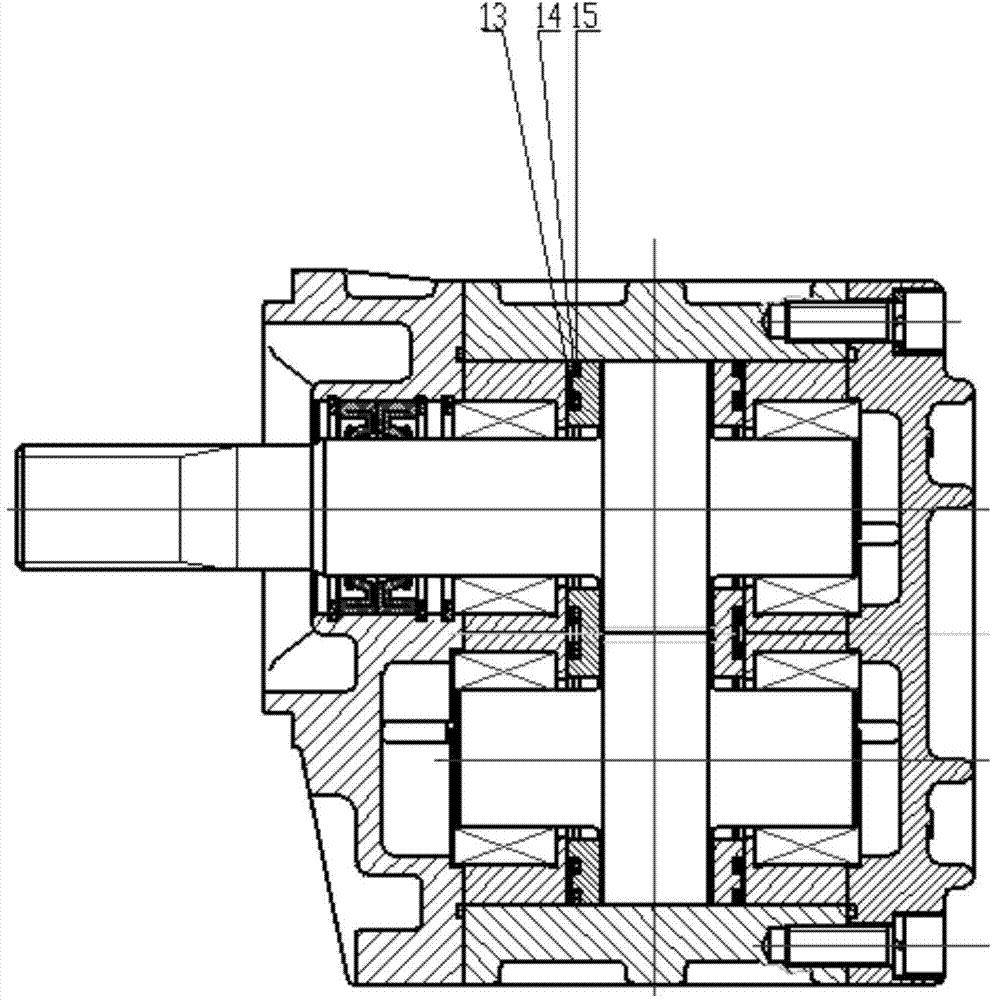

[0022] like figure 1 and figure 2 A floating side plate for a high-pressure large-displacement gear pump is shown, including a side plate body, an unloading groove 3 provided on the reverse thrust surface of the side plate body, an oil hole 7, a driving gear shaft hole and a driven gear The shaft hole and the compensation force groove 15 arranged on the compensation surface of the floating side plate are also provided with an ear-shaped high-pressure oil tank 1 on the reverse thrust surface of the floating side plate. A set of arc-shaped grooves, the central inflection point of the joint of the two sets of arc-shaped grooves is set concentrically with the oil hole 6, and communicated with the oil hole 6, both ends of the arc-shaped groove are located on the side of the oil suction chamber, so that the high pressure area Expand to the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com