Electromagnetic Flowmeter with Fluid Impedance Measurement

An electromagnetic flowmeter and electromagnetic flow technology, applied in the direction of fluid resistance measurement, application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, etc., can solve the problem of difficult to distinguish the change of fluid conductivity, without considering the input of the measuring amplifier Impedance and other issues, to achieve the effect of easy control and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

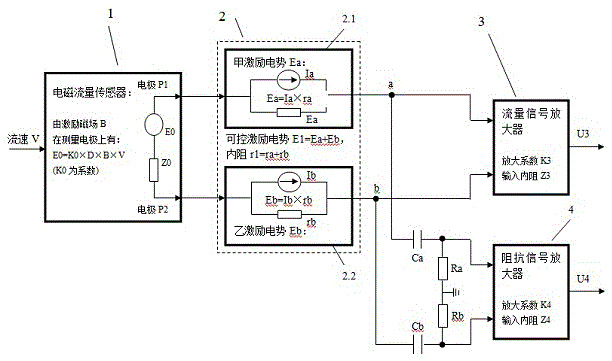

[0024] see figure 1 , the electromagnetic flowmeter with fluid impedance measurement, including: an electromagnetic flow sensor 1 with a pipe diameter D to allow the measured fluid Q to pass through, the electromagnetic flow sensor 1 has an excitation magnetic field B applied to the measured fluid Q, corresponding to the fluid Q The flow velocity V of the electromagnetic flow sensor 1 generates an induced potential E0 =K0×D×B×V whose amplitude is proportional to the flow velocity V between the two measuring electrodes P1 and P2, where K0 is a coefficient; a controllable excitation potential 2 generates a The excitation potential E1 of the internal resistance r1 and the alternating frequency f; the induction potential E0 is connected in series with the excitation potential E1 to form two signal terminals a and b; it is characterized in that the signal terminals a and b are input to a magnification factor K3 A flow signal amplifier 3; the signal terminals a and b are respectivel...

Embodiment 2

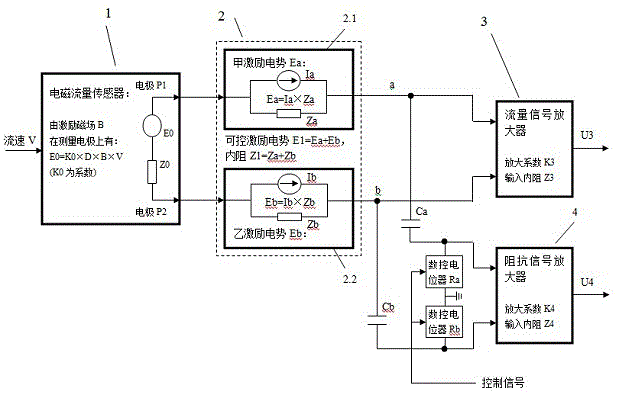

[0035] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0036] At figure 2 As shown, the resistors Ra and Rb can be implemented with digitally controlled potentiometers, which can be adjusted to the required resistance value according to actual needs, thereby improving the measurement accuracy.

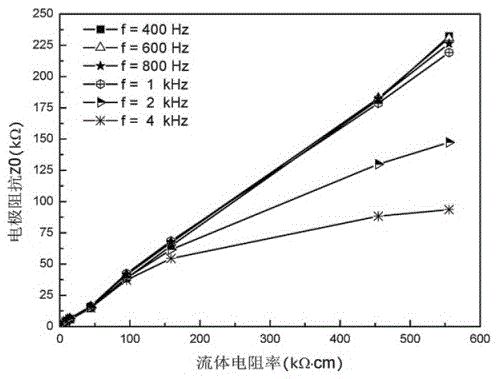

[0037] In this embodiment, the selection of the frequency f of the excitation signal generated by the controllable excitation potential 2 is described.

[0038] The impedance signal amplifier 4 used for electrode impedance measurement is capacitively coupled to the fluid signal measurement circuit. The capacitive reactance presented by the coupling capacitor at the magnetic excitation frequency must be large enough, and the capacitive reactance presented at the alternating frequency f must be relatively large. Small. Therefore, the electric excitation alternating frequency f is generally much larger than the magnetic ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com