Reliability testing table for multistage tandem chip removing devices

A technology of chip conveyor and tandem type, which is applied in the field of multi-stage tandem chip conveyor reliability test bench, can solve the problems of long test period, inability to simulate working conditions, and inability to test multiple chip conveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

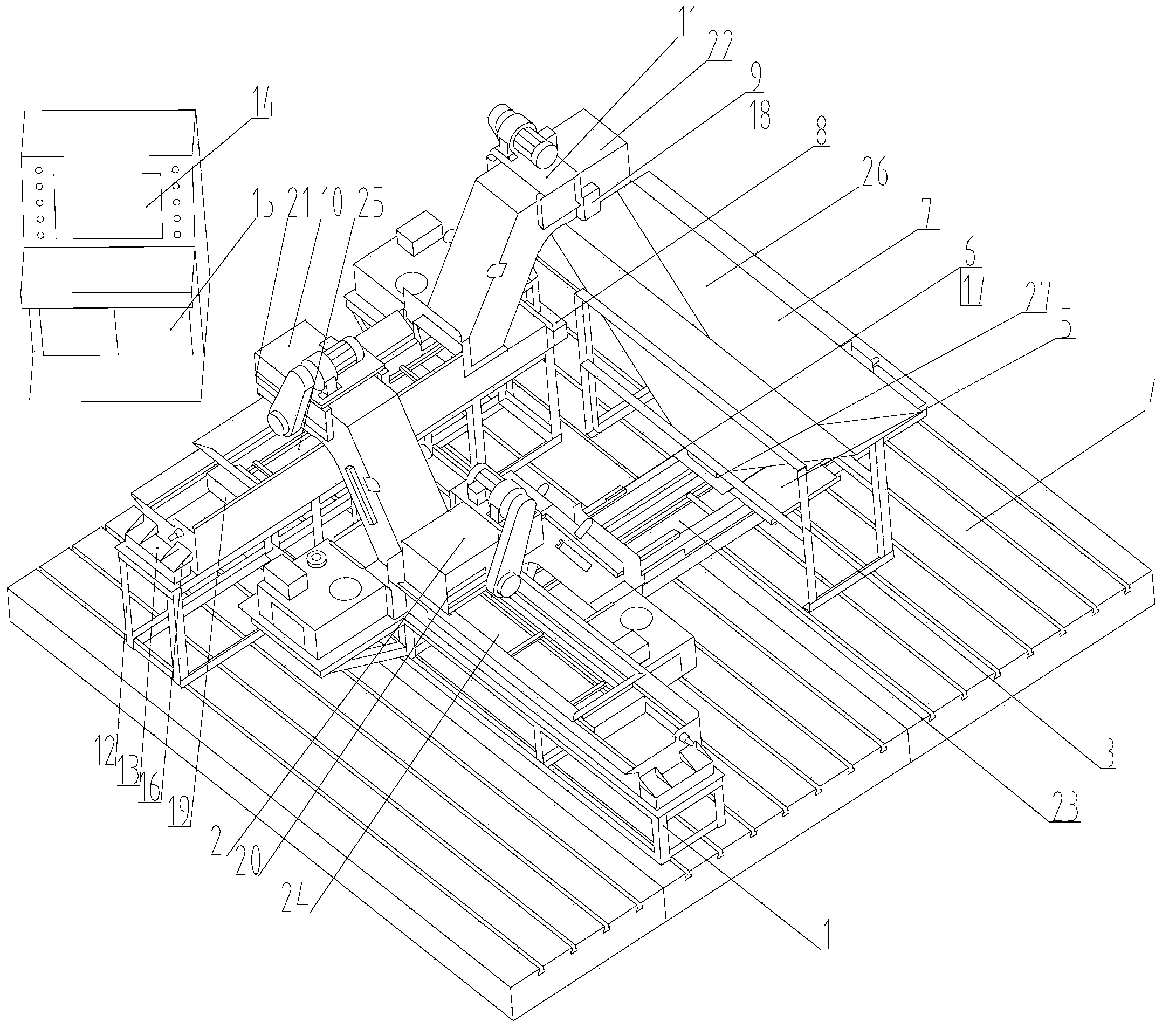

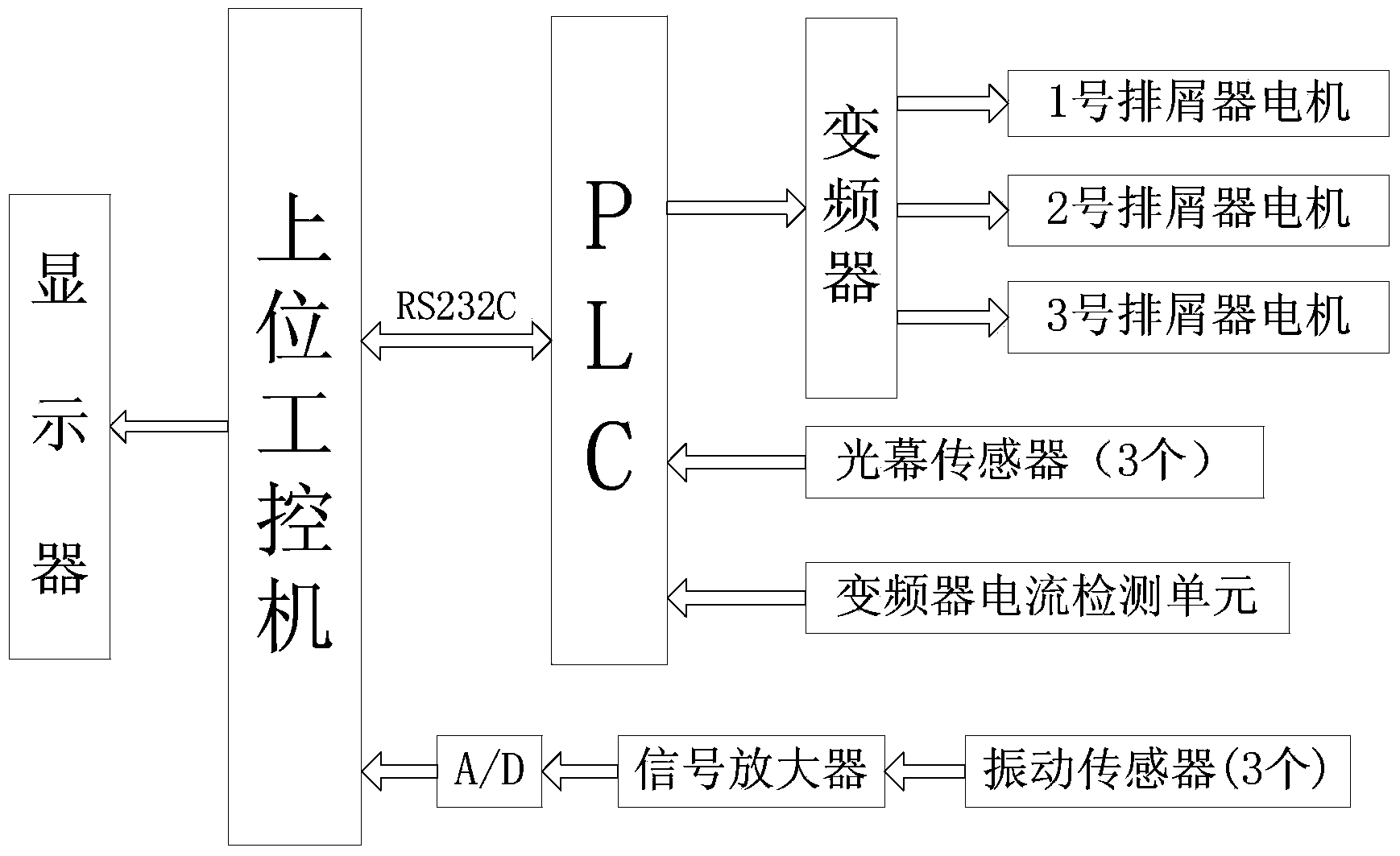

[0031] refer to figure 1 , the multi-stage tandem chip conveyor reliability test bench (in this embodiment, a multi-stage tandem chip conveyor reliability test bench formed by connecting three chip conveyors in series) includes a circular chip removal mechanism, a state detection Alarm mechanism and variable speed automatic control mechanism.

[0032] 1. Circular chip removal mechanism

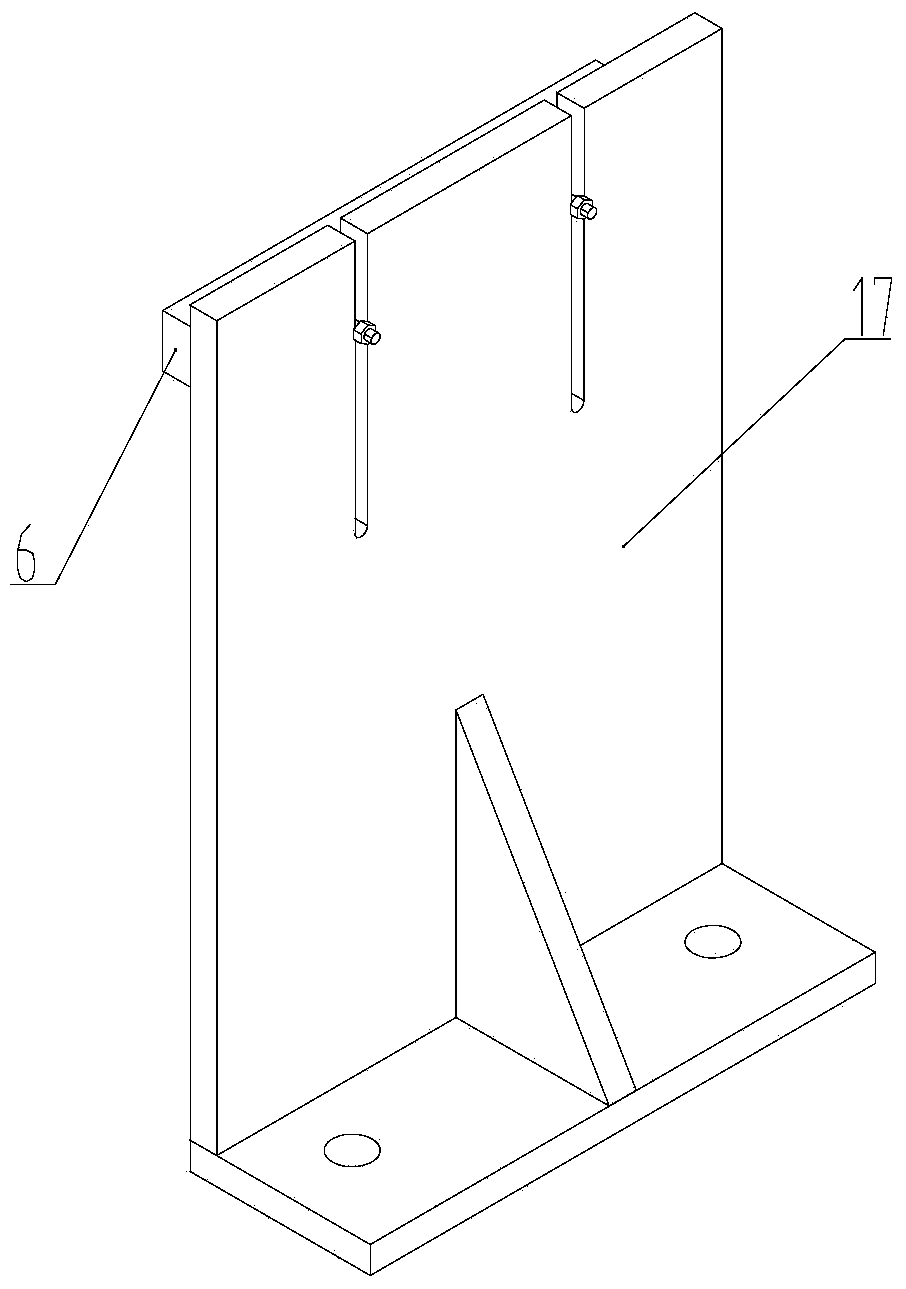

[0033] The circulating chip removal mechanism includes No. 1 chip conveyor 2, No. 2 chip conveyor 10, No. 3 chip conveyor 11, chip collector 7, No. 1 support frame 1, No. 2 support frame 12, and No. 3 support frame 3. Horizontal iron 4, front support block (3 pieces), rear support block (3 pieces), fixed angle steel (6 sets, including bolts, nuts, spring washers); No. 1 support frame 1, No. 2 support frame 12, ground level The front support block and the rear support block are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com