A wind tunnel test process verification method with mixed implementation of practical operation and simulation

A technology of wind tunnel test and verification method, which is applied in the field of wind tunnel test, and can solve problems such as burning, affecting wind tunnel equipment and personnel safety, and damage to wind tunnel equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

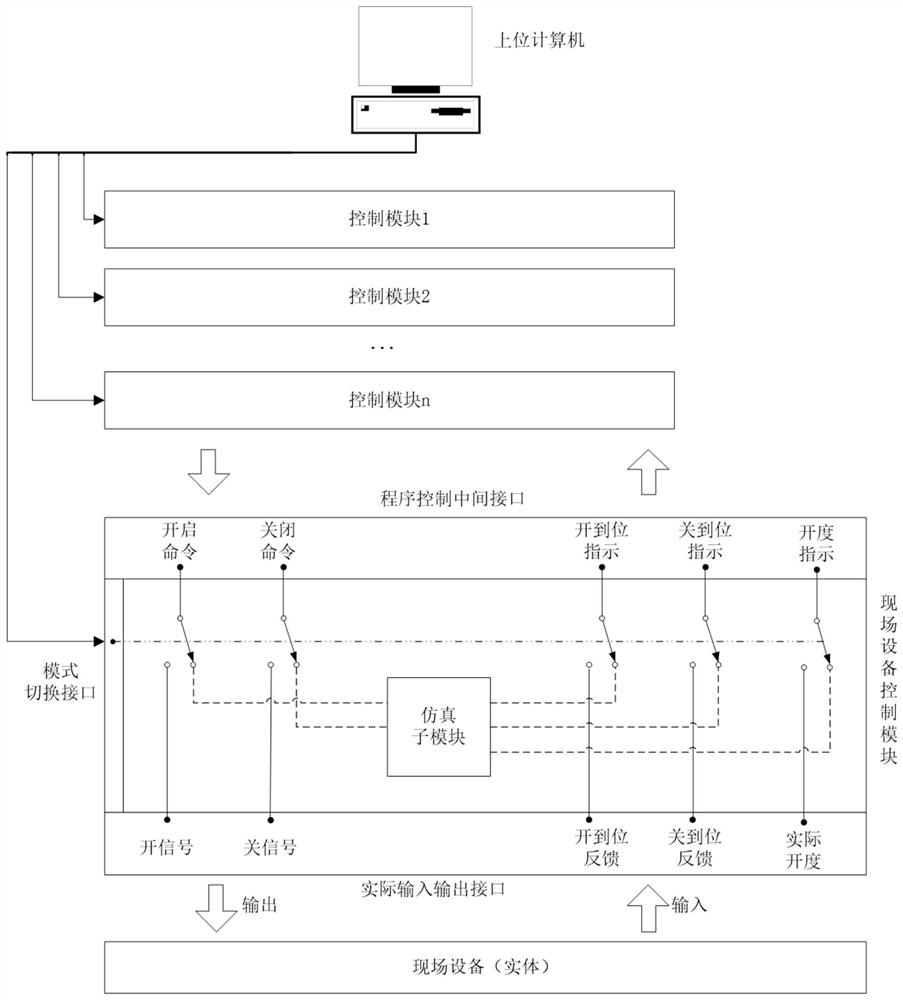

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is an application example of a hypersonic high temperature wind tunnel. The specific situation is as follows: the newly revised test procedure requires that the air throttle valve be opened when T=0 seconds; the main air valve be opened when T=1 second; If the valve opening is greater than 60%, it will be transferred to the liquid oxygen filling process, otherwise it will be transferred to the emergency stop operation process. At the same time, since the main valve has been repaired due to wear, it is necessary to actually check the operating status of the main valve. Set the main valve to "actual operation" and other equipment to "simulation". When the test process is executed, there is no medium flow in the wind tunnel, and the system is safe. While verifying the test process, the actual condition of the main valve is also confirmed. According to the data given by the valve manufacturer, the full opening time of the throttle valve is 4 seconds, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com