Water immersion ultrasonic phased-array detection device and detection method of disc part of aero-engine

A technology of aero-engine and ultrasonic phased array, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of decreased detection efficiency, frequent replacement of probes, and small thickness range, so as to improve detection efficiency and improve detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

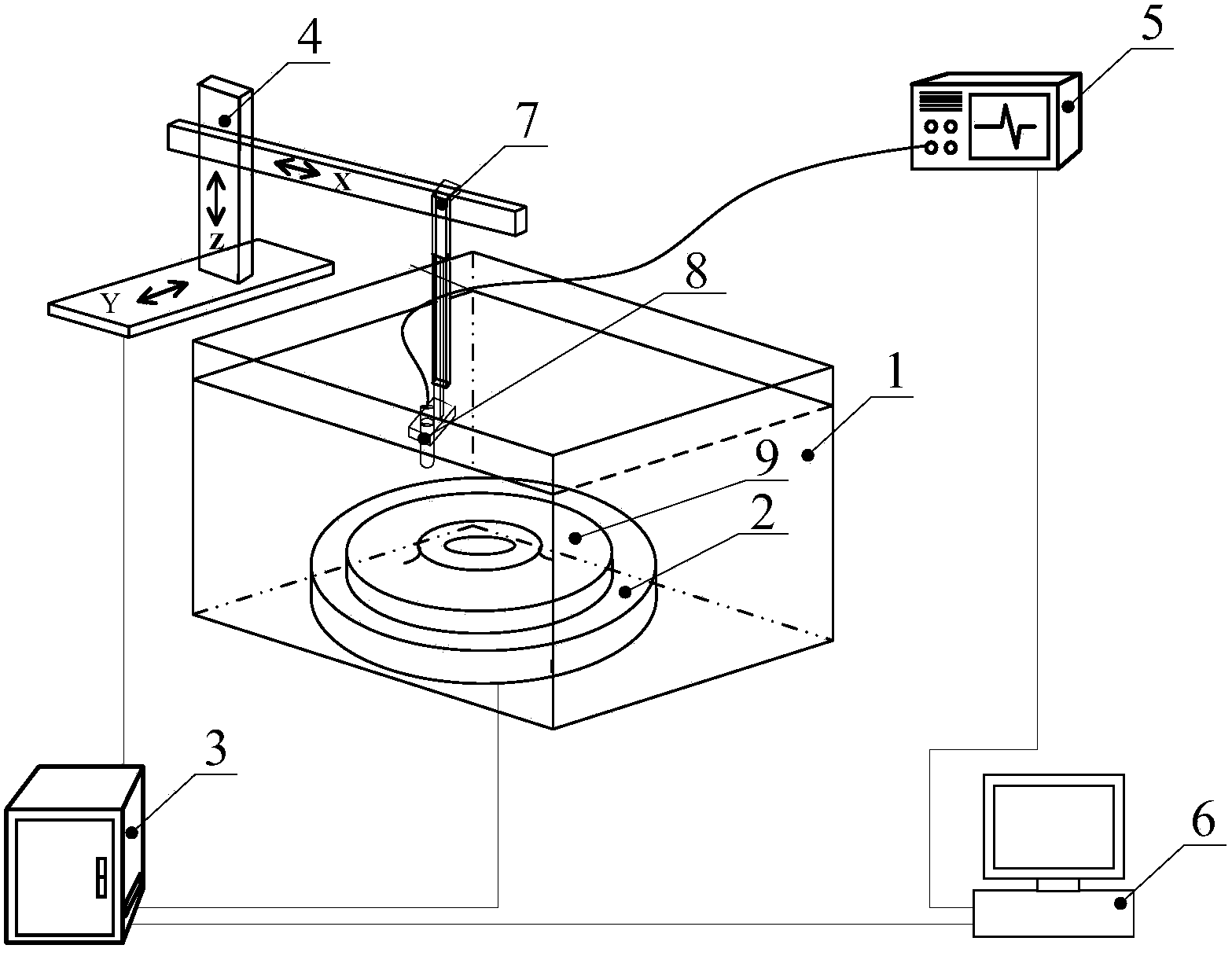

[0032] Example 1, detecting a certain type of aero-engine low-pressure compressor disk.

[0033] The turntable 2, the three-dimensional moving device 4, the ultrasonic phased array flaw detector 5, the control computer 6 and the ring array ultrasonic phased array probe 8 in the water immersion ultrasonic phased array device for the disk parts of the aero-engine of the present invention are all finished parts . The outer diameter of the disk is 580mm, and the thickness is 80mm. The detection steps are as follows:

[0034] 1. System connection: Submerge the ring array ultrasonic phased array probe 8 and the aero-engine disk parts 9 to be inspected in the flaw detection tank 1, and connect the turntable 2, the control cabinet 3, the three-dimensional mobile device 4, and the ultrasonic phased array flaw detection Cables for instrument 5, control computer 6 and ring array ultrasonic phased array probe 8;

[0035] 2. Obtain and record ultrasonic echo signals:

[0036] 2.1. Deter...

Embodiment 2

[0045] Example 2, detecting a certain stage of high-pressure turbine disk of a certain type of aero-engine.

[0046] The turntable 2, the three-dimensional moving device 4, the ultrasonic phased array flaw detector 5, the control computer 6 and the ring array ultrasonic phased array probe 8 in the water immersion ultrasonic phased array device for the disk parts of the aero-engine of the present invention are all finished parts . The outer diameter of the disc is 620mm and the thickness is 126mm. The detection steps are:

[0047] 1. System connection: Submerge the ring array ultrasonic phased array probe 8 and the aero-engine disk parts 9 to be inspected in the flaw detection tank 1, and connect the turntable 2, the control cabinet 3, the three-dimensional mobile device 4, and the ultrasonic phased array flaw detection Cables for instrument 5, control computer 6 and ring array ultrasonic phased array probe 8;

[0048] 2. Obtain and record ultrasonic echo signals:

[0049] 2...

Embodiment 3

[0057] Example 3, detecting the front seal plate of a certain type of aero-engine turbine.

[0058] The turntable 2, the three-dimensional moving device 4, the ultrasonic phased array flaw detector 5, the control computer 6 and the ring array ultrasonic phased array probe 8 in the water immersion ultrasonic phased array device for the disk parts of the aero-engine of the present invention are all finished parts . The outer diameter of the disc is 610mm and the thickness is 66mm. The detection steps are as follows:

[0059]1. System connection: Submerge the ring array ultrasonic phased array probe 8 and the aero-engine disk parts 9 to be inspected in the flaw detection tank 1, and connect the turntable 2, the control cabinet 3, the three-dimensional mobile device 4, and the ultrasonic phased array flaw detection Cables for instrument 5, control computer 6 and ring array ultrasonic phased array probe 8;

[0060] 2. Obtain and record ultrasonic echo signals:

[0061] 2.1. Dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com