A high-reliability multi-channel na-level micro-current transmission design method

A design method and micro-current technology, applied in the direction of measuring current/voltage, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problem of low indicators, waste of time, and restriction of electronic components in the detection and screening of automatic test systems for capacitor insulation resistance. The development of device screening and detection has achieved the effect of solving the problem of inspection and ensuring normal transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

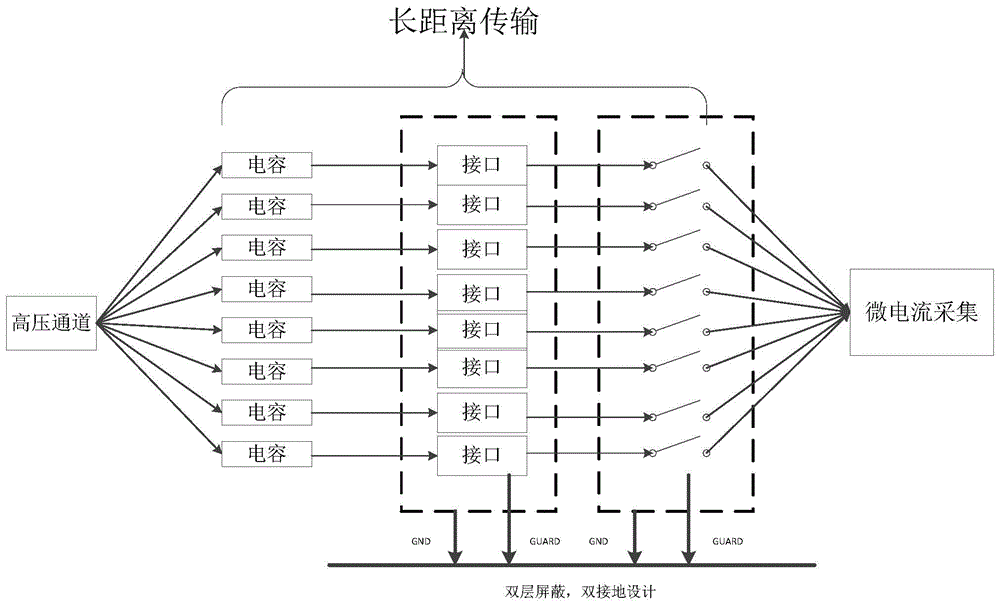

[0033] combine figure 1 , a multi-channel nA level micro-current transmission design method, comprising the steps of:

[0034] a Shielding protection and seamless connection design steps to ensure that micro-current signals are not disturbed by the outside world; specifically include:

[0035] a1 The entire micro-current circuit is fully shielded;

[0036] a2 Select double-shielded cables as connecting cables to achieve multi-layer protection and minimize external interference of micro-currents;

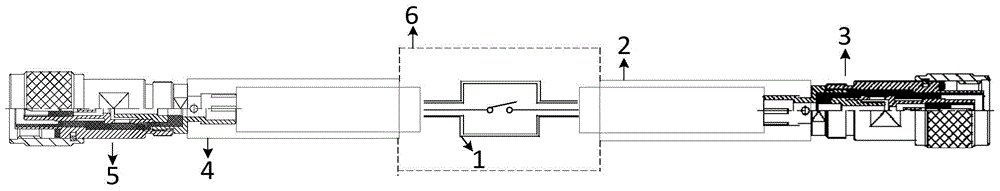

[0037] a3 Choose double-shielded connectors, which are consistent with the above-mentioned double-shielded cables, so that the micro-current transmission process can be seamlessly connected to ensure that the circuit is not disturbed by the leakage current of the material insulation;

[0038] a4 Select a wiring relay, the connector of the wiring relay is an SMA connector to ensure that the entire micro-current transmission process is a floating design, and the outer layer of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com