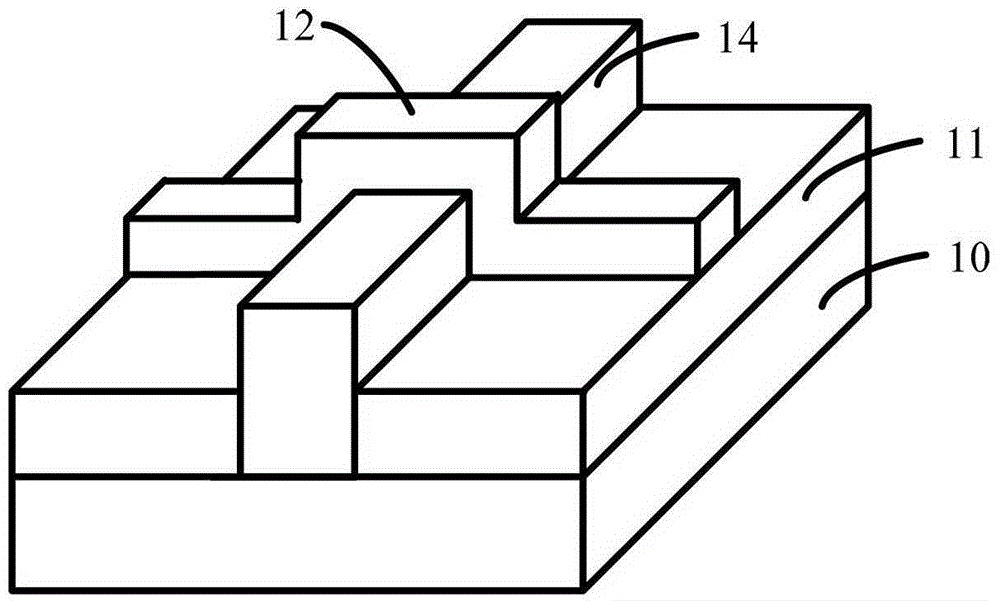

Method of forming fin and method of forming fin field effect transistor

A fin-type field effect and transistor technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems that it is difficult for FinFET to obtain technology nodes, and the performance of transistors needs to be further improved, so as to achieve size reduction and reduction Defects, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

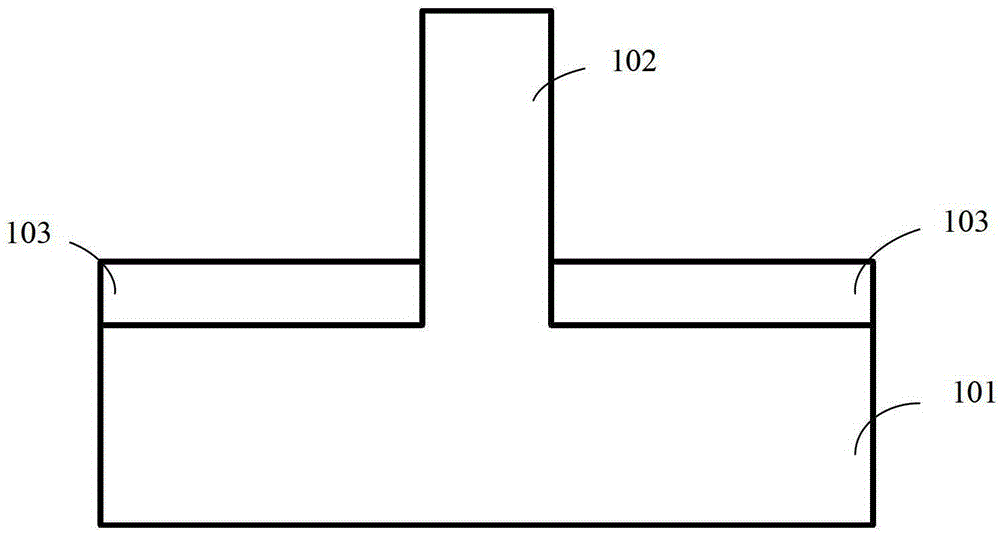

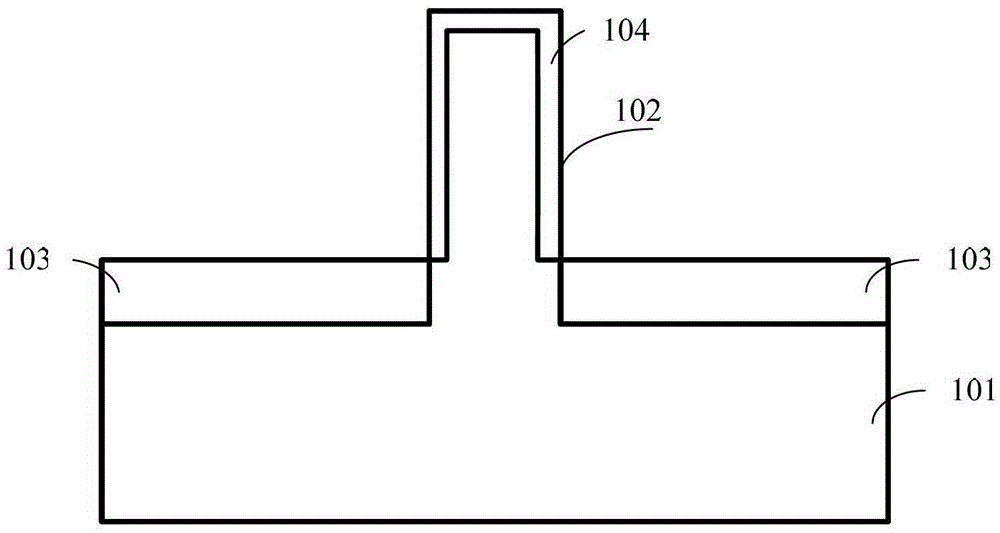

[0032] As mentioned in the background art, it is difficult to further reduce the technology node of the fin size by the method of forming the fin in the prior art, and the performance of the fabricated fin field effect transistor is not stable enough.

[0033] After research, it is found that it is difficult to further reduce the size of the fin portion of the FinFET due to the limitation of the existing technology such as single photolithography or etching process due to the limitation of its own technology such as photolithography resolution. Further, in the prior art, there is a gap between the fin and the gate, and there is a leakage current, which affects the performance and stability of the device.

[0034] Further studies have found that the reason for the gap between the fin and the gate is that the existing technology uses chemical etching or reactive ion etching when forming the fin to cause damage to the surface of the fin, resulting in gaps on the surface of the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com