Container formation method for low-liquid type lead-acid battery

A lead-acid battery, internalization technology, applied in lead-acid battery, lead-acid battery construction, secondary battery charging/discharging and other directions, can solve the problems of low production efficiency, high production cost, large power consumption, etc., to improve production Efficiency, high uniformity, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments.

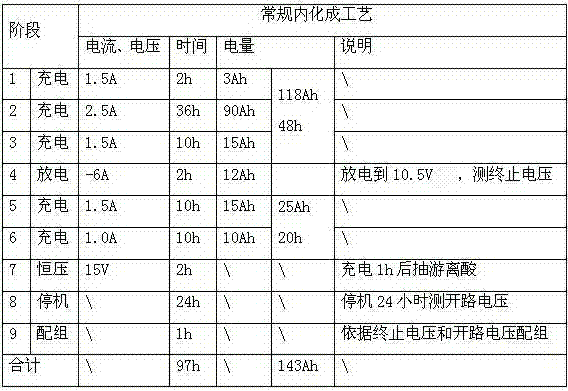

[0038] For the internal formation process of the 12V12Ah lean-liquid lead-acid battery, it includes the following steps:

[0039] Step 1: Add acid to the battery and place the acid-added battery in a water bath for cooling;

[0040] Step 2: Connect the battery to the wire and perform the first stage charge, first stage discharge, second stage charge and second stage discharge on the battery respectively;

[0041] Step 2.1: The specific steps of the first stage of charging are:

[0042] (1) The first charge: charge the battery for 2 hours with 1.5A current;

[0043] (2) Second charge: Charge the battery for 26 hours with 2.5A current;

[0044] (3) The third charge: charge the battery for 10 hours with a current of 2A;

[0045] (4) The fourth charge: charge the battery for 8 hours with 1.5A current;

[0046] (5) The fifth charge: charge the battery for 8 hours with 1A current;

[0047] (6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com