Wire coating material, insulated wire, and wire harness

A wire covering material and wire harness technology, applied in the direction of insulated cables, plastic/resin/wax insulators, insulators, etc., can solve the problems of difficult insertion of terminals, buckling of wires, etc., and achieve the effect of reliable insertion of terminals and excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

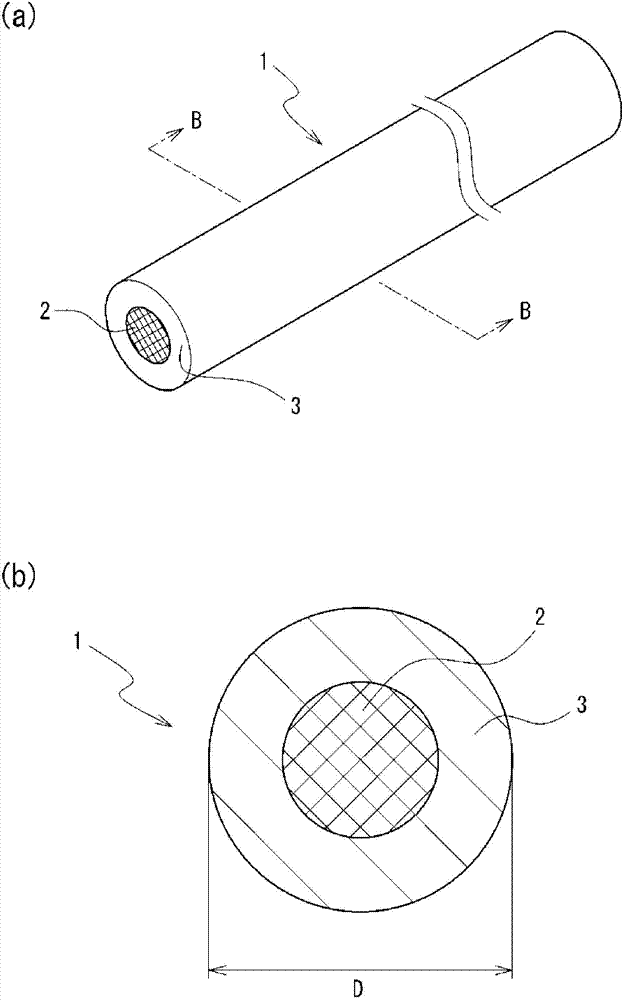

Image

Examples

Embodiment 1~25

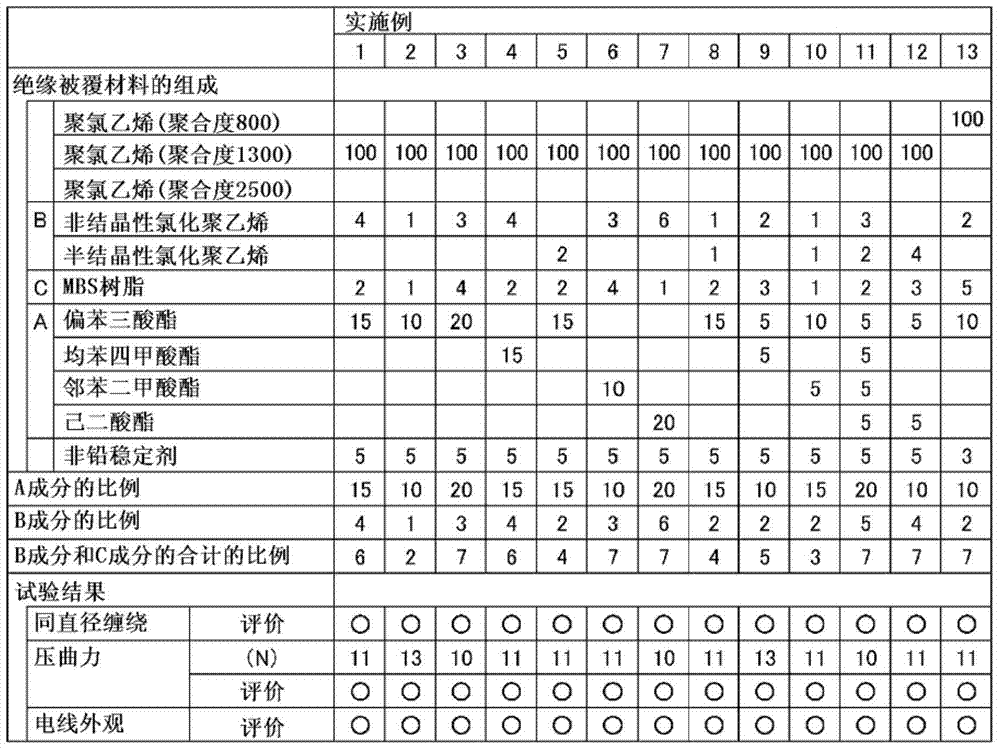

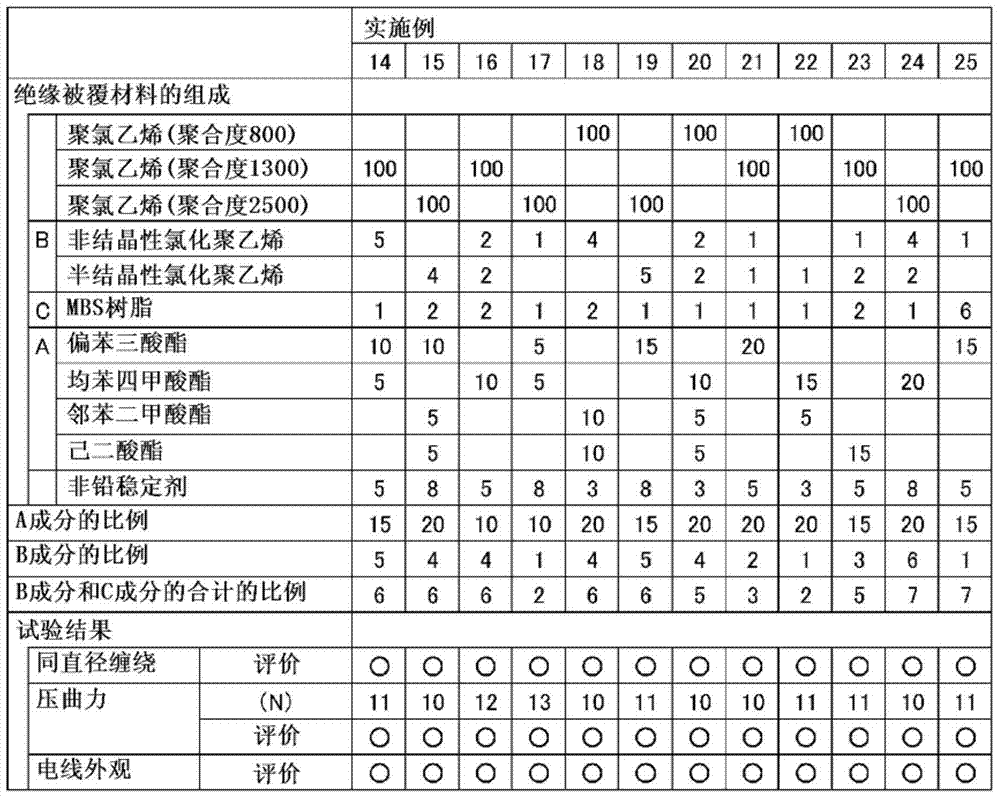

[0045] Examples 1-25, Comparative Examples 1-14

[0046] (Preparation of wire coating materials)

[0047] As shown in Tables 1 to 3, the components such as polyvinyl chloride, plasticizer (component A), chlorinated polyethylene (component B), MBS resin (component C), and lead-free stabilizers are listed in Tables 1 to 3. The indicated mixing amount (parts by mass) was mixed using a uniaxial extruder at 180°C, and formed into pellets using a granulator to prepare a polyvinyl chloride composition.

[0048] (Production of insulated wire)

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com