Single cylinder-driven plugging-clamping-type aperture disk seedling transplanting paw

A technology of plug seedlings and single cylinder, which is applied in the field of agricultural machinery, can solve the problems of inability to meet the requirements of large plug seedling plants, unreasonable design of end transplanting claws, and high rate of damage to seedlings, so as to achieve reliability guarantee, High working rate and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

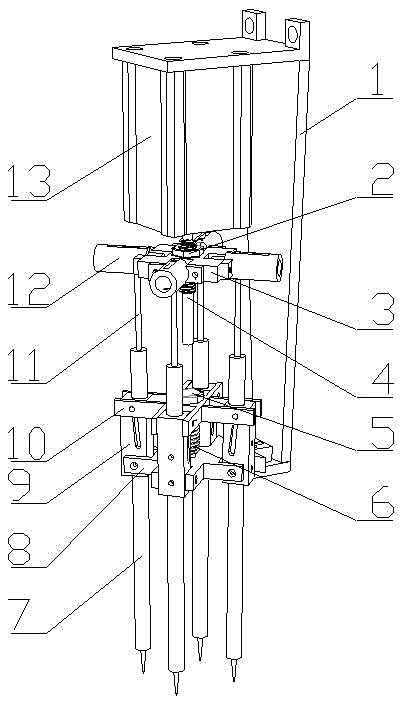

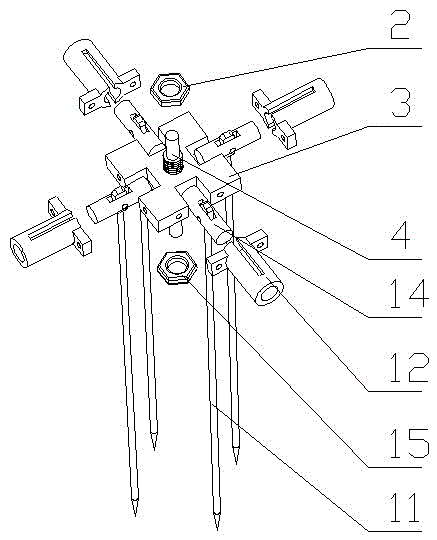

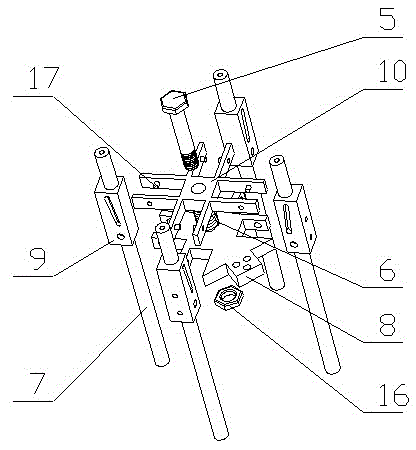

[0014] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes mounting bracket 1, three nuts 2,15,16, seedling needle mounting plate 3, threaded push rod 4, bolt 5, spring 6, four seedling withdrawal needle tubes 7, needle tube mounting plate 8, four Needle tube fastening rotating part 9, middle pressing plate 10, four seedling-taking needles 11, four seedling needle fastening slides 12, driving cylinder 13, four cylindrical slide blocks 14 and eight sliding cylindrical short pins 17; driving cylinder 13 Fixedly installed under the upper plate of the mounting bracket 1, the cylinder rod of the driving cylinder 13 is fixedly connected with one end of the threaded push rod 4 installed in the square seedling needle mounting plate 3 downward; the seedling needle mounting plate 3 passes through the first nut 2 and The second nut 15 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com