Abrasive water cutting and fire extinguishing device

A cutting device and abrasive water technology, applied in abrasives, abrasive jet machine tools, fire rescue, etc., can solve the problems of high labor intensity, easy to generate high temperature, and complicated process of demolition tools, and achieve high demolition efficiency and strong cutting ability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

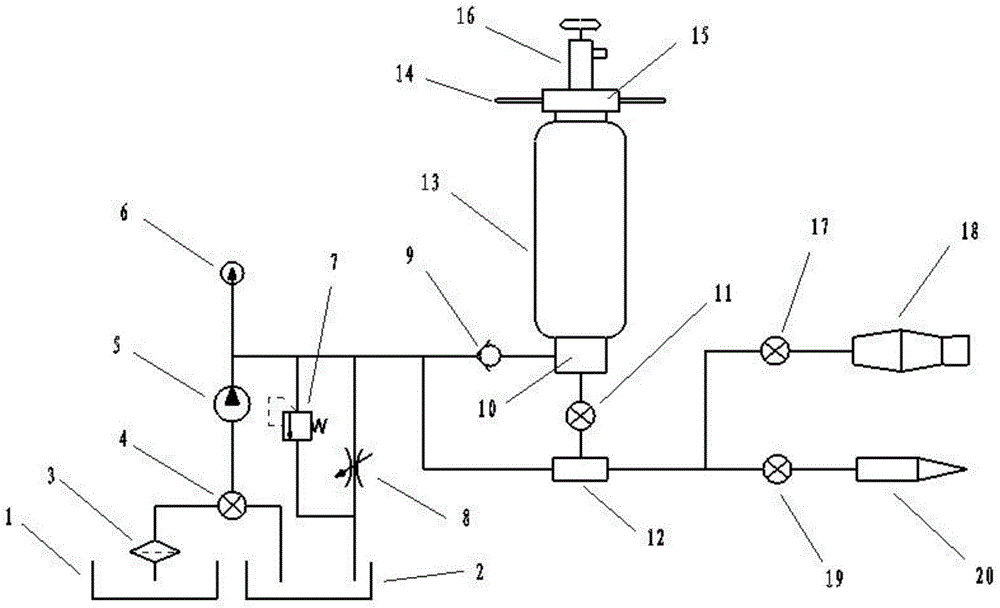

[0015] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings.

[0016] As shown in the figure, the abrasive water cutting and fire extinguishing device includes water tank 1, foam liquid tank 2, filter screen 3, switching valve 4, high pressure pump 5, pressure gauge 6, safety valve 7, pressure regulating valve 8, and pressure relief valve 16. Screw cap 15, handle 14, abrasive pot 13, base 10, one-way valve 9, abrasive shut-off valve 11, abrasive mixing chamber 12, foaming shut-off valve 17, foam nozzle 18, cutting shut-off valve 19, cutting nozzle 20, etc. .

[0017] The high-pressure liquid supply system consists of water tank 1, foam liquid tank 2, filter screen 3, switching valve 4, high-pressure pump 5, pressure gauge 6, safety valve 7, and pressure regulating valve 8; switching valve 4, water tank 1, and foam liquid tank 2 Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com