Automatic material preparing device

A technology of automatic cutting and driving device, applied in metal processing and other directions, can solve the problems of poor popularity, time-consuming and labor-intensive, hidden safety hazards, etc., and achieve the effects of low cost, convenient cutting and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

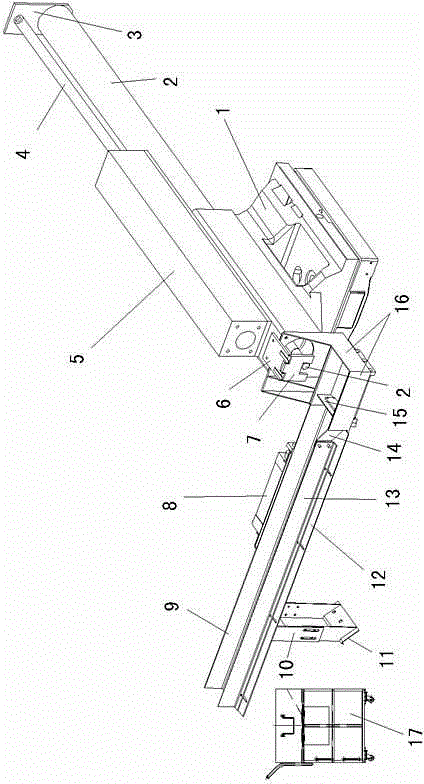

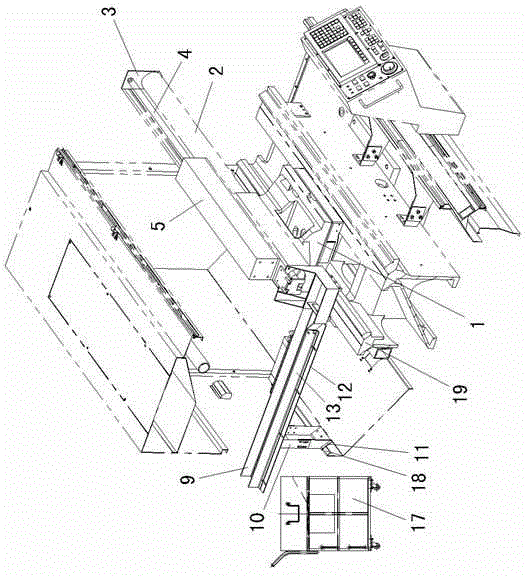

[0010] like figure 1 As shown: 1 is the tailstock body, the upper part of the tailstock body 1 is axially penetrated with a slide bar 2, and the slide bar 2 can slide axially relative to the tailstock body 1. One end of the slide bar 2 is connected to the driving device. The driving device is fixedly connected with the oil cylinder 5 connected with the hydraulic mechanism on the tailstock body 1, and the outer end of the piston rod 4 matched with the oil cylinder 5 is connected with an end of the slide bar 2 through the connecting plate 3. When oil cylinder 5 moves, connecting plate 3 and slide bar 2 can be driven by piston rod 4 to move.

[0011] The front end of the tailstock body 1 is screwed with a flat plate 6 arranged horizontally, and the end of the flat plate 6 is fixedly connected with a baffle plate 7 arranged vertically. The other end of slide bar 2 is positioned at the opening below baffle plate 7, and the termination of slide bar 2 can reciprocate at the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com