Double-end-face grinding machine for automobile oil pump valve spools

A double-end, grinding machine technology, applied in machine tools suitable for grinding workpiece planes, grinding workpiece supports, grinding/polishing equipment, etc., can solve problems such as machining accuracy and quality cannot be guaranteed, and meet fixture accuracy requirements. Low, good synchronization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

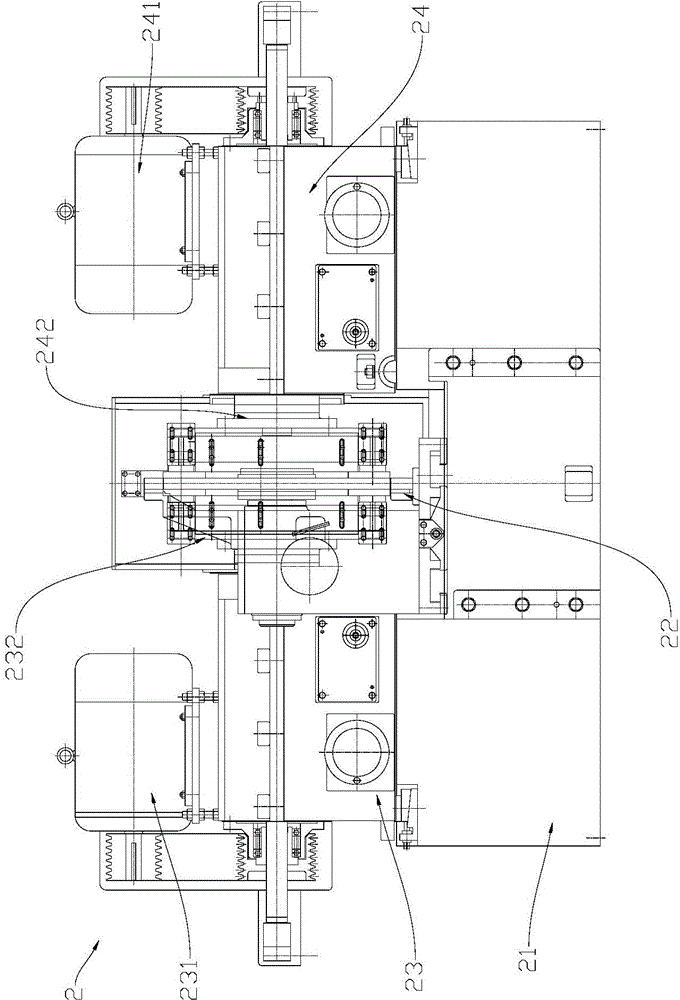

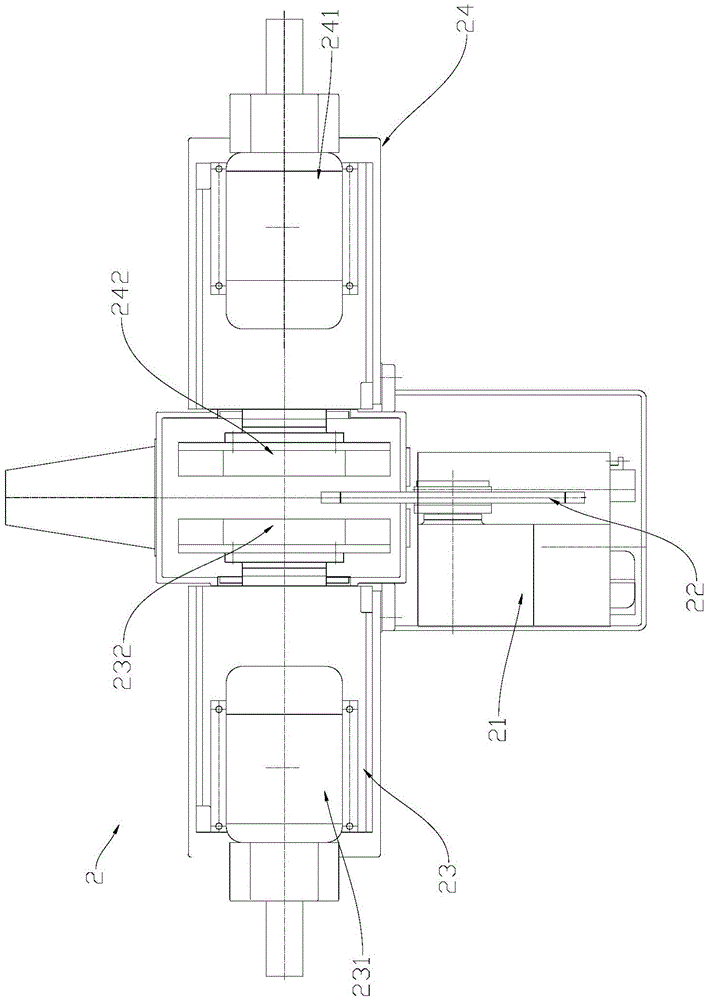

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0019] Such as figure 2 and image 3 As shown, the present invention discloses a double-face grinding machine for an automobile oil pump spool 1 , which includes a bed 21 , a clamp 22 , a first grinding device 232 and a second grinding device 242 .

[0020] The bed 21 is fixedly arranged on the ground. The bed 21 is the working platform of the grinding machine and is used to provide support for the entire grinding machine.

[0021] The jig 22 is provided on the bed 21 . The jig 22 has a centerline parallel to the longitudinal direction. The jig 22 is bilaterally symmetrical with respect to the center line.

[0022] The automotive oil pump v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com