Expansion drum device for tyre retreading and tyre retreading method

A tire retreading and inflation drum technology, applied in tires, applications, household appliances, etc., can solve problems such as complex structures, and achieve the effect of easy operation, easy use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

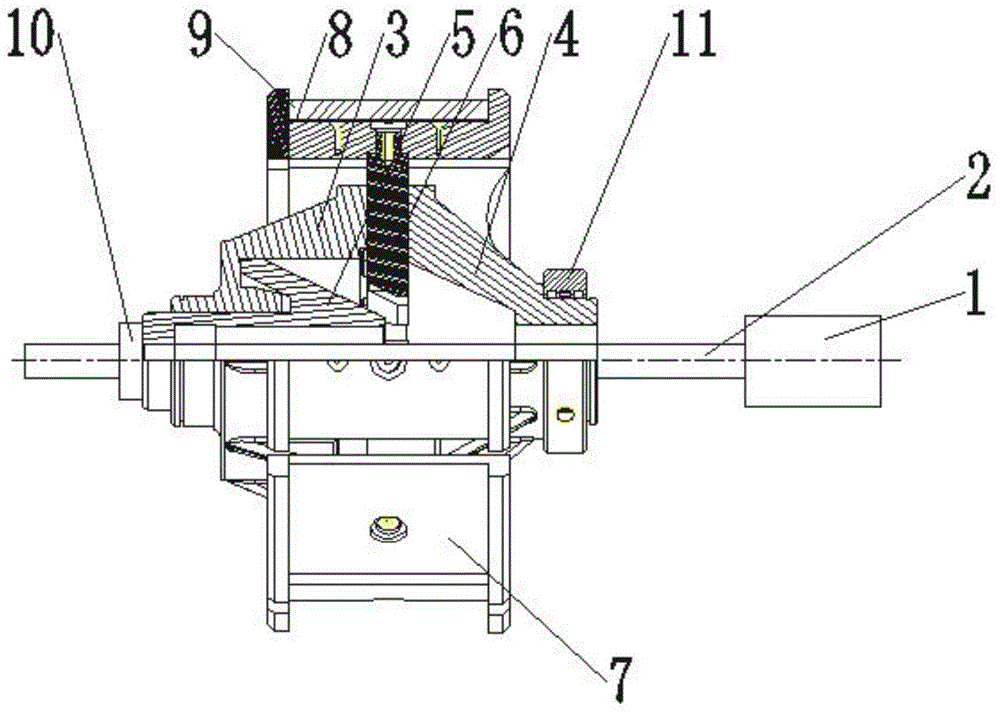

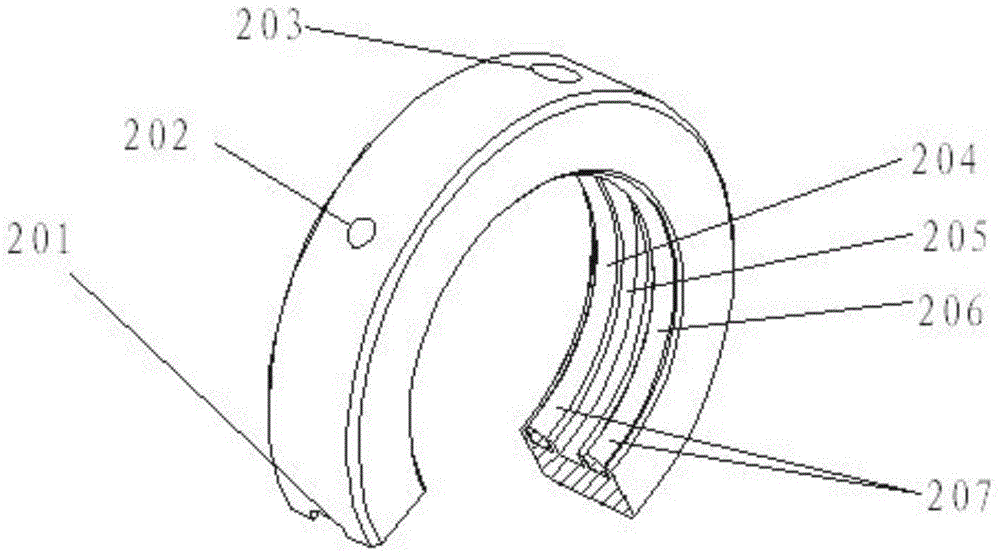

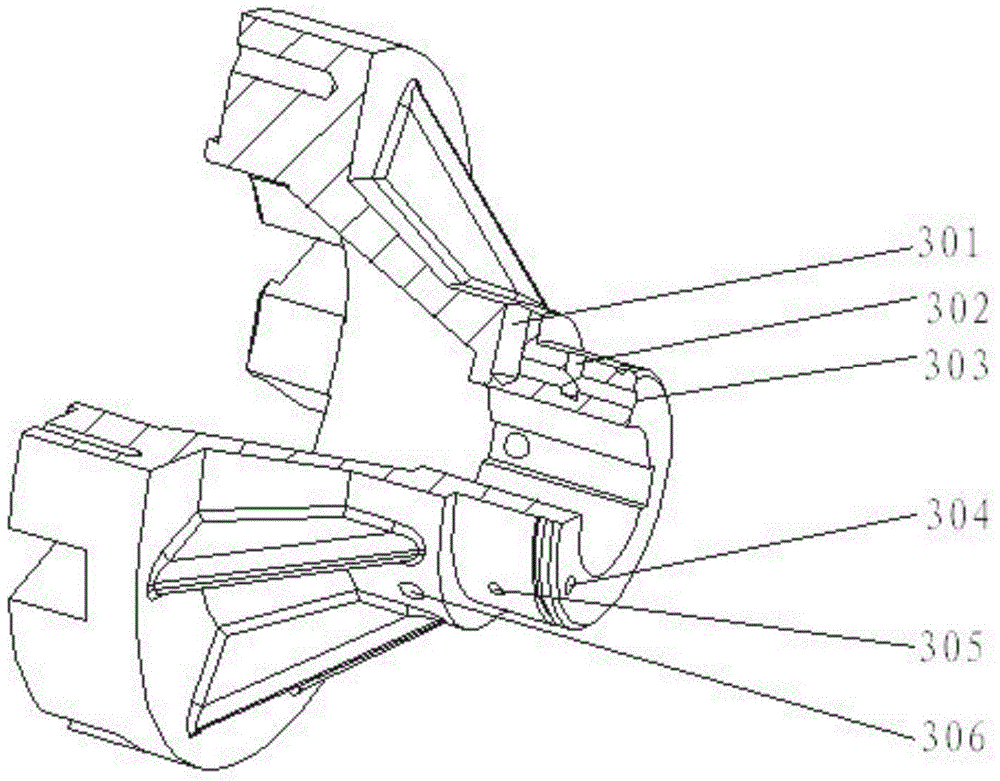

[0024] like figure 1 As shown, an expansion drum device for tire retreading includes a cylinder 1, a main shaft 2, a left disc 3, a right flange 4, a taper shaft 5, a radial shaft 6, an expansion plate 7, an iron ring 8, and a rubber sleeve 9, Snap ring 10, inflatable sealing ring 11. A taper shaft 5 is installed inside the left disk 3, and the taper shaft 5 is connected with the main shaft 2. There are eight radial shafts 6 (the number can be determined according to the size of the left disc 3 and the right flange 4), which are evenly distributed in the grooves of the right flange 4, and the radial shaft 6 is connected with an expansion plate 7, radial The lower end of the shaft 6 is an inclined surface, which is connected with the tapered surface of the tapered shaft 5 . The left disk 3 and the right flange 4 are connected by bolts, the snap ring 10 is at the front end of the main shaft 2, and the cylinder 1 pulls the tapered shaft 5 through the snap ring 10 to move axiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com