Interface enhancer for watering-type pavement material preparation and application thereof

An interface enhancer and pavement material technology, applied in the field of interface enhancers, can solve the problems of difficult to control demulsification time, complicated construction, slow resin curing, etc., achieve significant economic benefits and application value, and solve the effect of insufficient crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

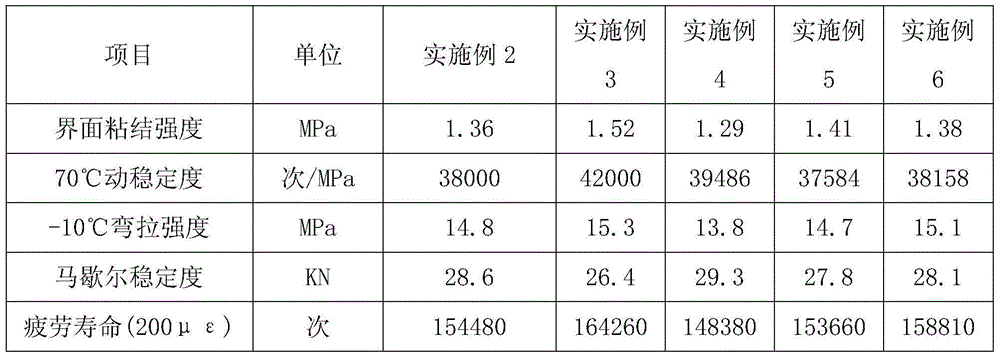

Examples

Embodiment 1

[0027] The preparation method of interface-enhanced pouring type pavement material, the steps are as follows:

[0028] 1) Preparation of interface enhancer:

[0029] Add acrylic acid monomer, organic silane, surfactant, and accelerator into the reaction kettle for polymerization reaction, the reaction temperature is 50°C, and the reaction time is 1.5h to obtain the interface enhancer;

[0030] in,

[0031] The parts by weight of each component are: 15 parts of acrylic acid monomer, 8 parts of organosilane, 1.5 parts of surfactant, and 0.025 part of accelerator;

[0032] Described acrylic acid monomer is that methacrylic acid and methyl acrylate are mixed in a mass ratio of 1:2;

[0033] The organosilane is vinyldimethylsilane;

[0034] Described tensio-active agent is stearic acid;

[0035] The accelerator is dicumyl peroxide and potassium persulfate with a mass ratio of 1:5.

[0036] 2) Preparation of highly connected void body asphalt mixture:

[0037] Stir the coarse ...

Embodiment 2

[0050] The preparation method of interface-enhanced pouring type pavement material, the steps are as follows:

[0051] 1) Preparation of interface enhancer:

[0052] Add acrylic acid monomer, organic silane, surfactant and accelerator into the reaction kettle for polymerization reaction, the reaction temperature is 40°C, and the reaction time is 0.5h to obtain the interface enhancer.

[0053] in,

[0054] The parts by weight of each component are: 10 parts of acrylic acid monomer, 5 parts of organosilane, 0.2 part of surfactant, and 0.01 part of accelerator.

[0055] The acrylic acid monomer is methacrylic acid.

[0056] The organosilane is vinyldimethylsilane;

[0057] Described tensio-active agent is stearic acid.

[0058] The accelerator is dicumyl peroxide and potassium persulfate with a mass ratio of 1:4.

[0059] 2) Preparation of highly connected void body asphalt mixture:

[0060] Stir the coarse aggregate and fine aggregate at 175°C in a mixing pot at 170°C for ...

Embodiment 3

[0073] The preparation method of interface-enhanced pouring type pavement material, the steps are as follows:

[0074] 1) Preparation of interface enhancer:

[0075] Add acrylic acid monomer, organic silane, surfactant, and accelerator into the reaction kettle for polymerization reaction, the reaction temperature is 40°C, and the reaction time is 2h, to obtain the interface enhancer.

[0076] in,

[0077] The parts by weight of each component are: 10 parts of acrylic acid monomer, 12 parts of organosilane, 0.2 part of surfactant, and 0.04 part of accelerator.

[0078] The acrylic acid monomer is butyl acrylate.

[0079] The organosilane is vinyltrimethylsilane;

[0080] Described tensio-active agent is stearic acid.

[0081] The accelerator is dicumyl peroxide and potassium persulfate with a mass ratio of 1:10.

[0082] 2) Preparation of highly connected void body asphalt mixture:

[0083] Stir the coarse aggregate and fine aggregate at 185°C in a mixing pot at 170°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com