Carbon fiber drawing machine

A drafting machine and carbon fiber technology, applied in the direction of drafting equipment, spinning machines, continuous winding spinning machines, etc., can solve the problem that the quality of carbon fiber production cannot be well guaranteed, and it is difficult to reduce the production quality of enterprises. Accurate control of rollers and other issues to achieve the effect of improving production quality, improving control accuracy, and improving enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

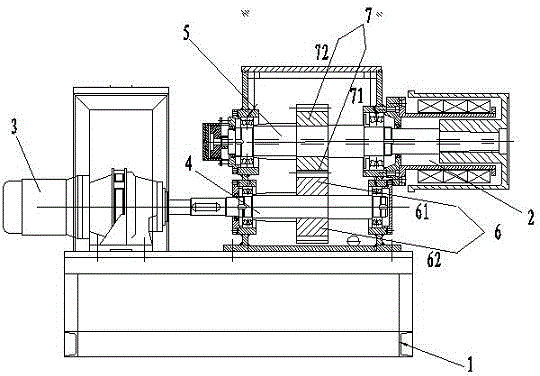

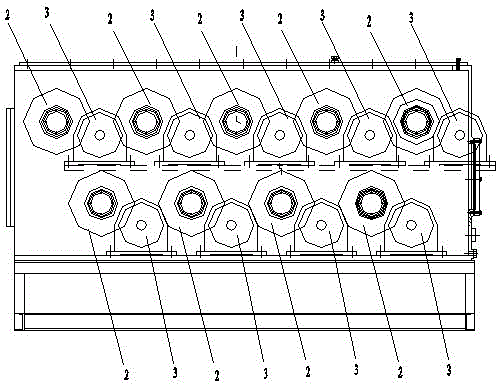

[0013] As shown in the figure, a carbon fiber drafting machine includes a frame 1, a roller 2 and a speed reducer 3, wherein the number of the speed reducer 3 is consistent with the number of the rollers 2, and each speed reducer 3 is arranged at Behind the roller 2, the reducer 3 is in a one-to-one relationship with the turning roller 2. The frame is provided with a first bearing 4 and a second bearing 5, and the first bearing 4 and the second bearing 5 are distributed in a long direction, and the first bearing 4 is provided with a first gear 6 outside the first gear. 6 meshes with the first bearing 4; a second gear 7 is arranged outside the second bearing 5, and the second gear 7 meshes with the second bearing 5; the first gear 61 meshes with the second gear 71. The speed reducer 3 is connected with the first bearing 4 , and the rotating roller 2 is connected with the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com