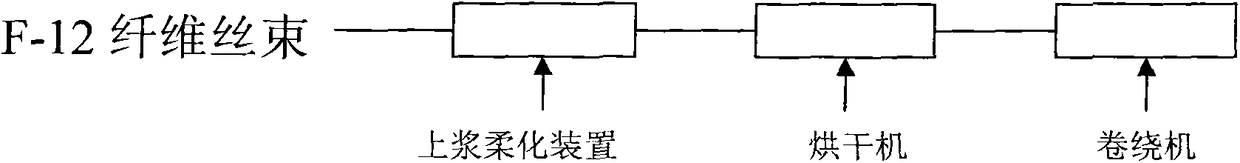

A kind of f-12 fiber sizing and softening method and sizing and softening device

A F-12, fiber technology, applied in the direction of fiber treatment, fiber type, ultrasonic/sonic fiber treatment, etc., can solve the problems of large surface inertia, poor surface infiltration, etc., to achieve increased surface activity, improved uniformity, and improved fiber wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

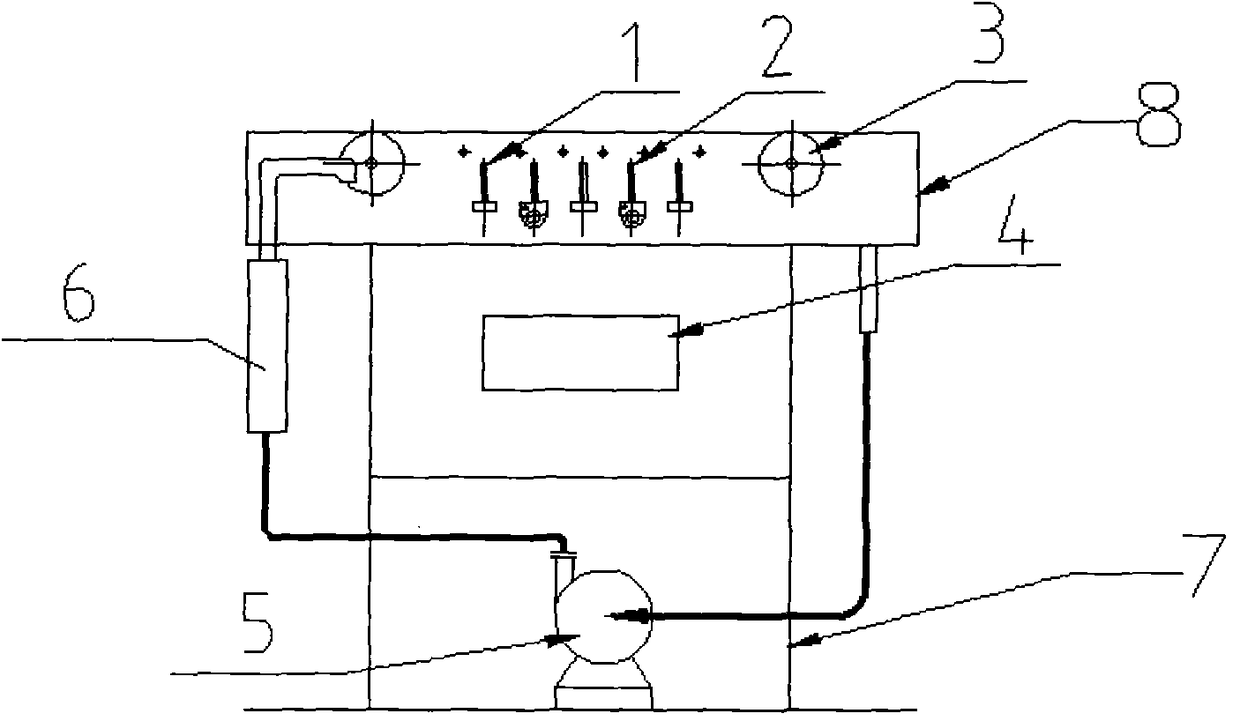

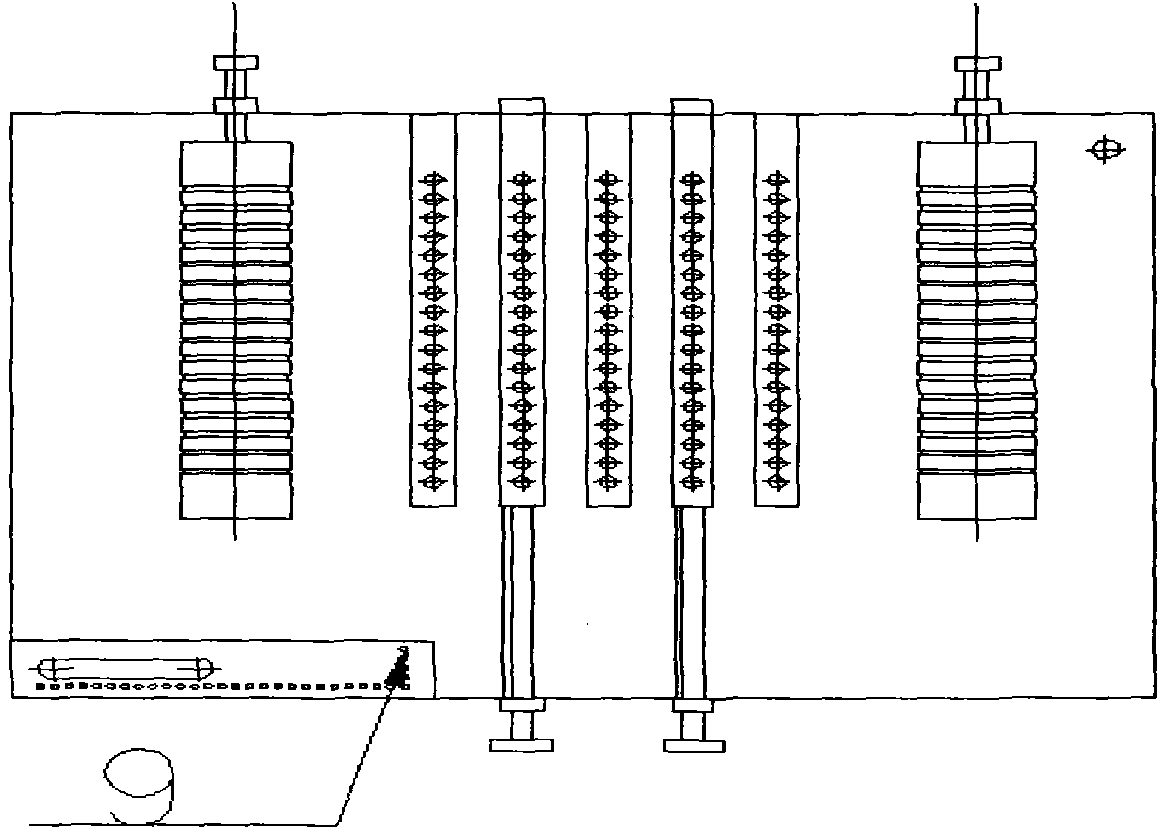

Embodiment 1

[0032] Before starting fiber sizing, first inject the fatty acid ester sizing agent with a concentration of 1.2% into the tank until the liquid level reaches the specified scale, open the liquid inlet valve and the liquid outlet valve, and open the liquid inlet valve to the half position. Then turn on the ultrasonic device, the ultrasonic power is 1200W, and the ultrasonic frequency is 28KHz; after the slurry in the tank has obvious vibration ripples, turn on the circulation pump, and the flow rate of the circulation pump is 0.3m 3 / h; Finally, turn on the heater and set the temperature control meter to 40°C. Then start the fiber sizing process, 16 rolls of 23tex fibers are sizing through the wire feeding machine at a speed of 22.9m / min through the godet roll and softening roll of the sizing and softening device, and the movable softening roll is adjusted to make the two screw Adjust the angle to 30°, then place the fiber at 95°C for drying and winding to obtain the finished f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com