Circularly progressively rolling type channel lining machine

A lining machine and roller compaction technology, which is applied in artificial waterways, water conservancy projects, buildings, etc., can solve the problems of inability to achieve rapid construction, the influence of the initial setting time of the construction speed, and uneven compactness, so as to facilitate mechanized construction, Save manpower, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

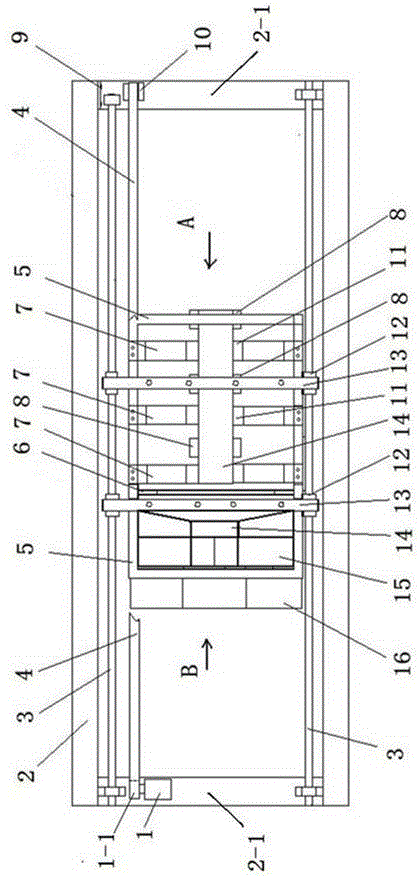

[0024] The lining machine is designed according to the standard section of channel with bottom width of 0.5m, side slope of 1:1 and depth of 0.5m.

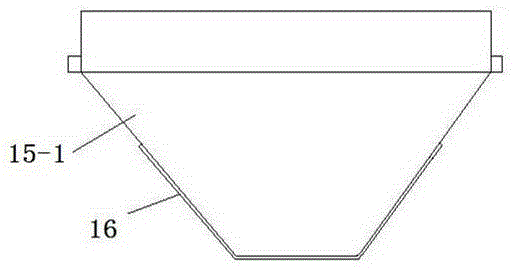

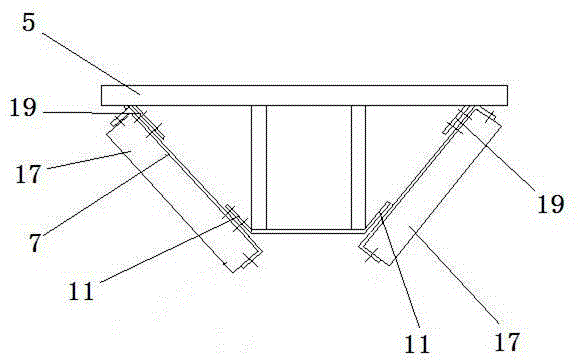

[0025] See figure 1 , 11 , is provided with support rails 2 on both sides of the channel that can be moved on both sides of the channel. The support rails 2 on both sides are connected to the right-angle connecting sides 9 of the beams 2-1 at both ends through bolts 9-1. The bolt hole is a long hole, and the bolt 9-1 constitutes a lining thickness adjustment device. At the same time, two side slide rails 3 parallel to the two sides along the support track are also provided, and both ends of the slide rail 3 are fixed on the two end beams 2-1; The sleeve 12 is slidably connected with the slide rails 3 on both sides. See figure 1 , 3 , 7-10, assemble the channel shaping bulldozer 16, the collecting hopper, the slitting device 6 and the rolling device in sequence from the front end to the rear end on the frame 5; 15-1. The rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com