Circular Progressive Rolling Type Channel Lining Machine

A lining machine and roller compaction technology, applied in artificial waterways, water conservancy projects, buildings, etc., can solve problems such as uneven density, inability to realize rapid construction, and influence of initial setting time of concrete at construction speed, so as to achieve simple operation and convenience Mechanized construction and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

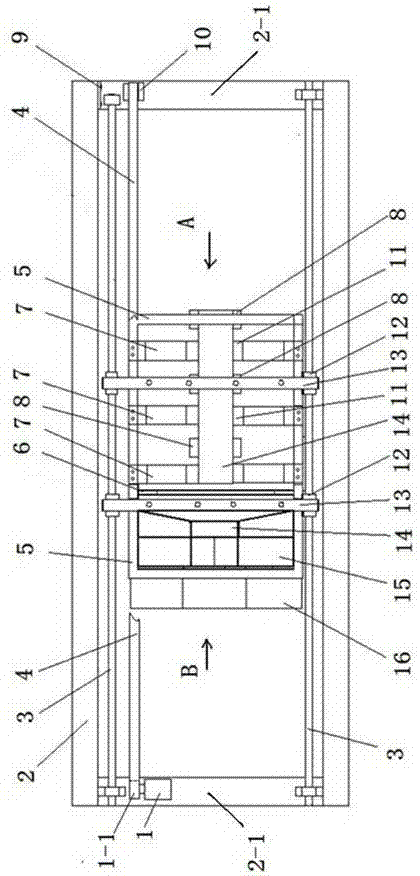

[0024] The lining machine is designed according to the channel as a standard section with a bottom width of 0.5m, a side slope of 1:1, and a depth of 0.5m.

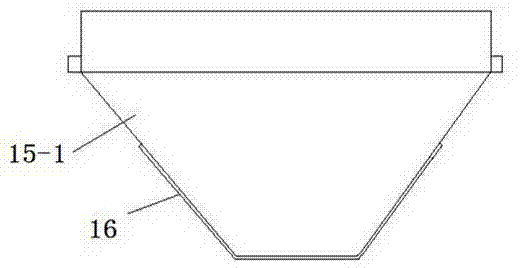

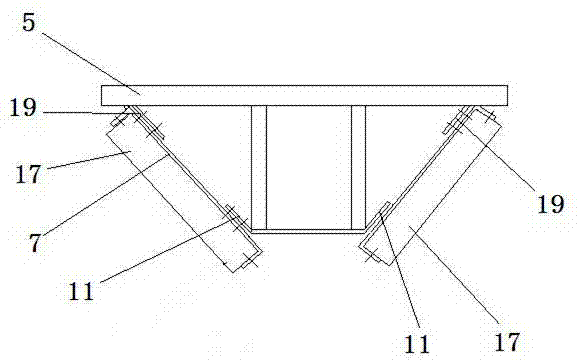

[0025] See figure 1 , 11 , are provided with support rails 2 on both sides of the channel that can be moved and placed on the upper edge of both sides of the channel, and the support rails 2 on both sides are connected to the right-angled connecting sides 9 of the crossbeams 2-1 at both ends through bolts 9-1, and the right-angled connecting sides 9 The bolt hole is a long hole, and forms a lining thickness adjusting device with the bolt 9-1. Simultaneously also be provided with both side slide rails 3 parallel to both sides along the support track, the two ends of the slide rail 3 are fixed on the crossbeams 2-1 at both ends; The sleeve 12 is slidably connected with the slide rails 3 on both sides. See figure 1 , 3 , 7-10, assemble channel shaping bulldozer 16, collecting hopper, slit device 6 and rolling device suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com