Construction method for drawing-resistant thorn-shaped pile

A construction method and anti-drawing technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of insufficient pulling force, loosening or longitudinal sliding, increased difficulty and cost, etc., and achieve lateral dynamic load resistance The effect of improving the ability, being easy to popularize and apply, and shortening the length of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

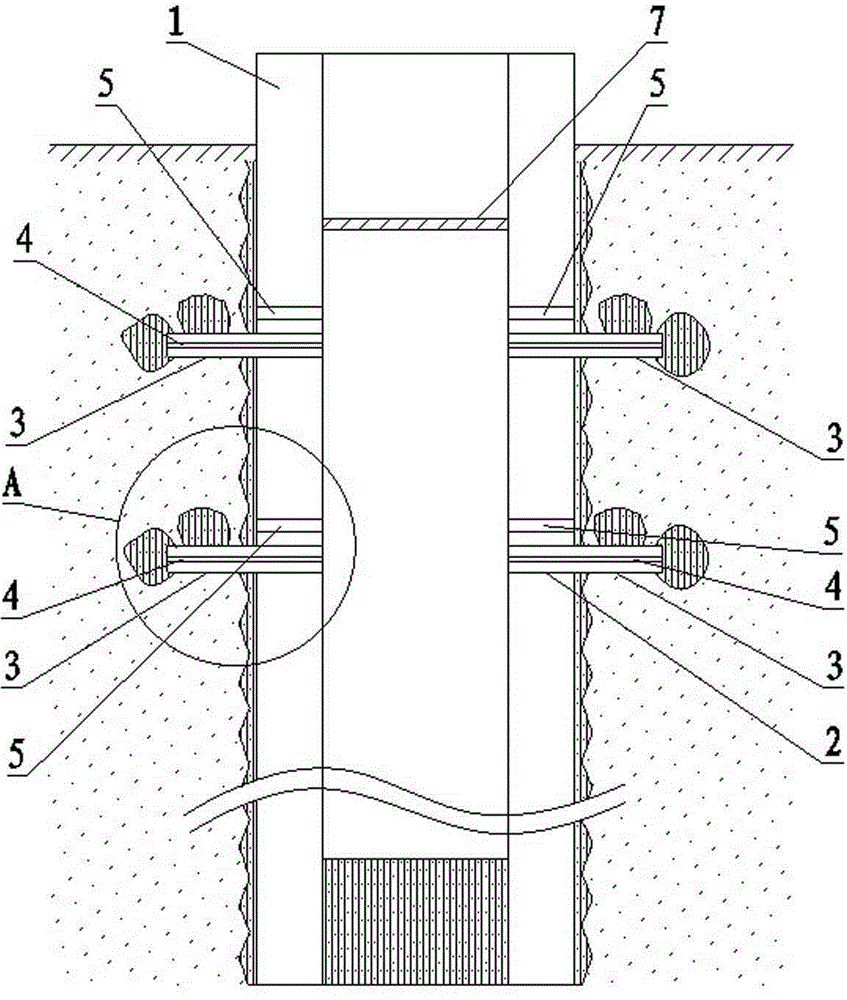

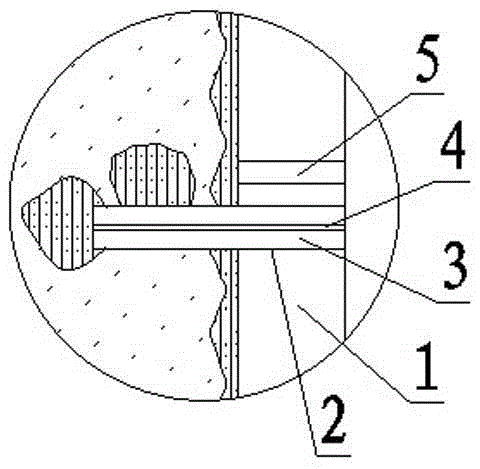

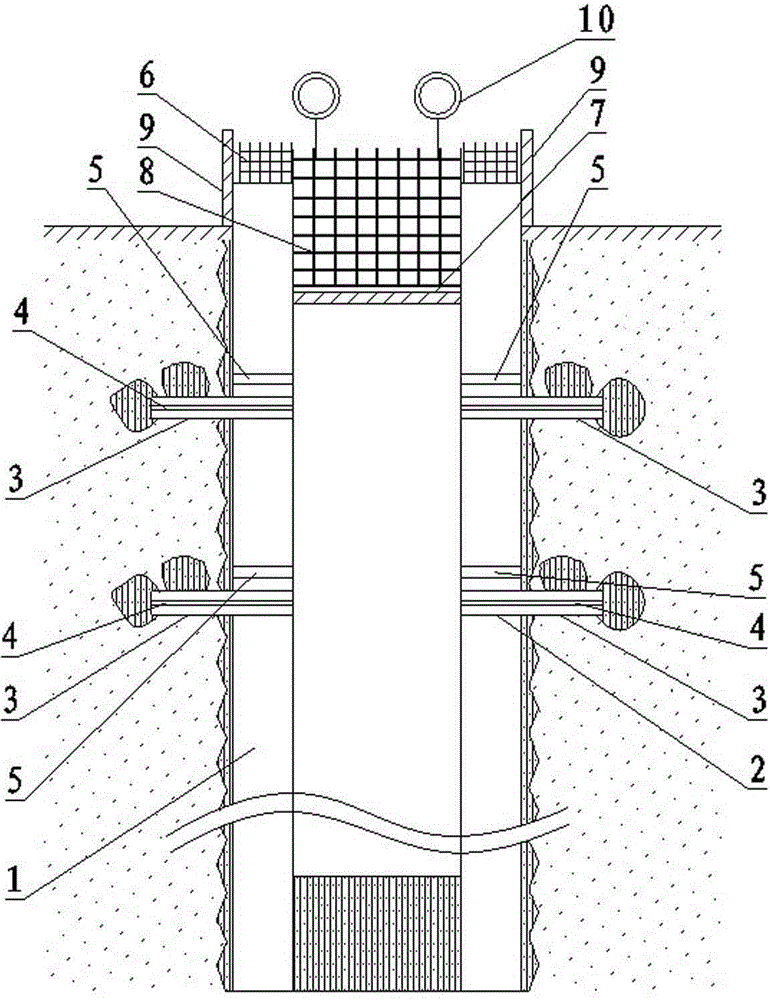

[0019] A construction method of a pullout-resistant thorn pile is carried out according to the following procedures:

[0020] A. Prefabricated pile: According to the design requirements, prefabricated a hollow reinforced concrete pile body 1 with a number of thorn pile holes 2 distributed on the surrounding wall. There is a direct opening on the wall of the reinforced concrete pile body 1 located on the upper part of each thorn pile hole 2. Grouting hole 5;

[0021] B. Pile down: The foundation soil forms a hole, and the reinforced concrete pile body 1 is lowered into the hole to the predetermined position; or the pile is sunk to the predetermined position while digging the hole;

[0022] C. Back cover: After the reinforced concrete pile body 1 is lowered to a predetermined position, concrete is poured along the hollow of the reinforced concrete pile body 1 to realize the bottom sealing of the inner bottom of the reinforced concrete pile body 1;

[0023] D. Pile pressing: Spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com