Sift-proof loader bucket

A technology for loaders and buckets, applied to mechanically driven excavators/dredgers, etc., can solve the problems of bulk material leakage, bulk material recovery and cleaning time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

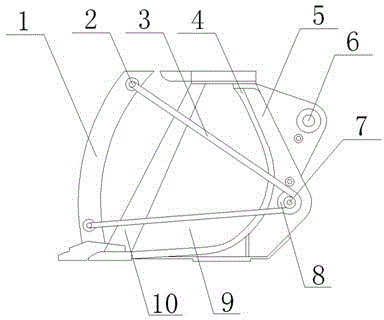

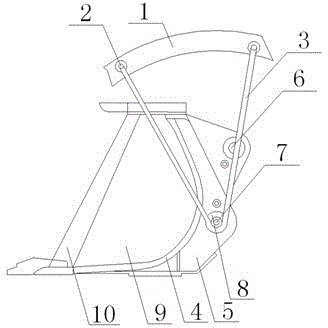

[0016] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the use status diagram of the present invention.

[0017] An anti-spill loader bucket of the present invention includes a bucket 5, ribs 4, connecting pins 6, side guards 9 and beams, wherein the bucket 5 is a "C"-shaped steel structure, and the bucket 5 The upper part of the outer arc is welded and fixed with a connecting pin 6, the connecting pin 6 is welded and fixed to the outside of the bucket 5, the lower part of the arc of the bucket 5 is provided with a motor 8, the output shaft of the motor 8 is provided with a rotating shaft 7, and the rotating shaft 7 and the motor 8 The output shaft is socketed, and a rotating arm 3 is arranged on the rotating shaft 7. The rotating arm 3 is a "V"-shaped bracket structure. The bottom end of the "V"-shaped bracket of the rotating arm 3 is welded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com