Water tank water inlet valve of float bucket integrated structure

A water inlet valve, integrated technology, applied in flushing equipment with water tanks, water supply devices, buildings, etc., can solve the problems of material consumption, not easy to disassemble, scattered parts of the water inlet valve, etc., to reduce production costs, The effect of improving production efficiency and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

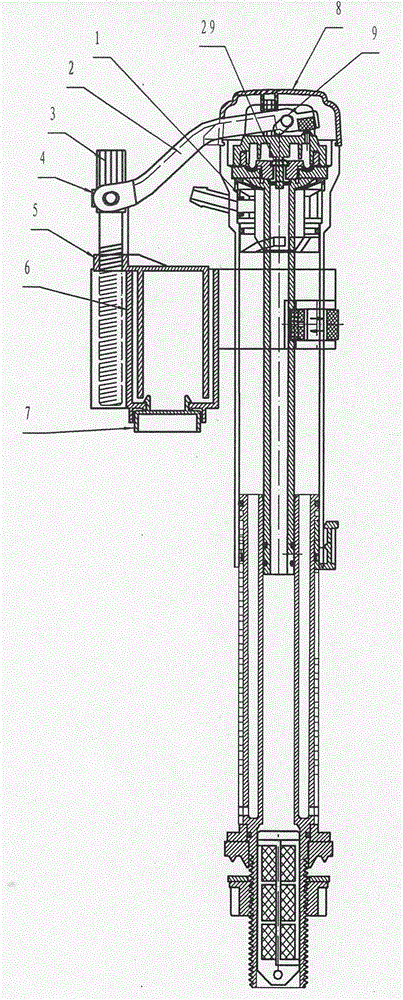

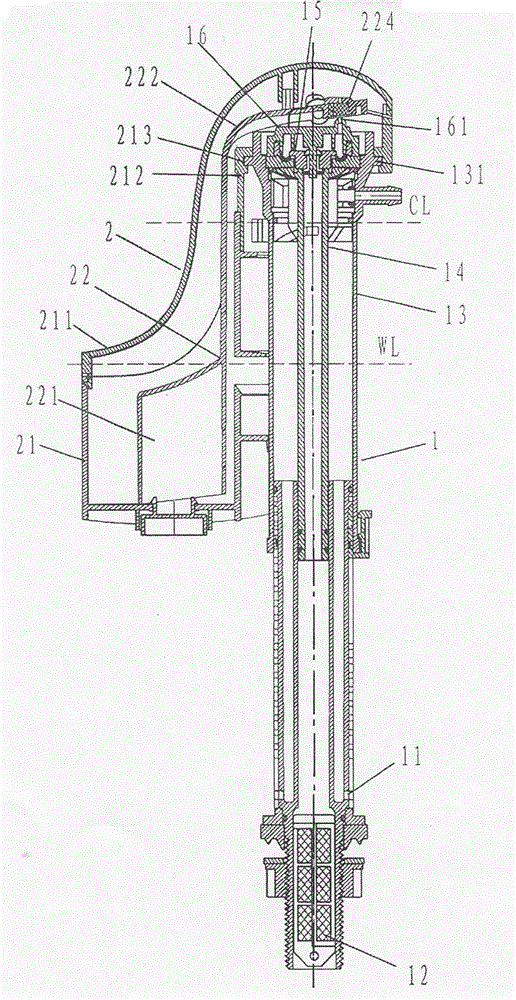

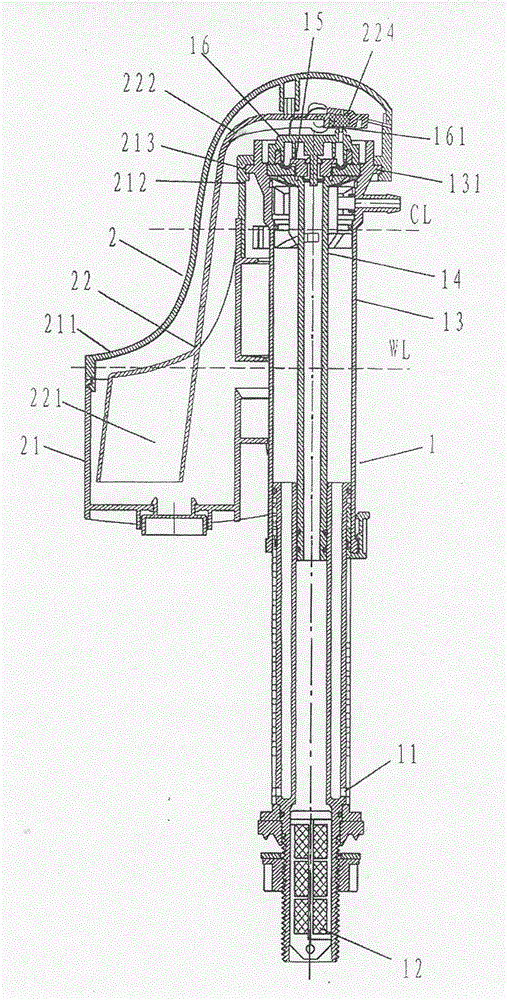

[0017] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, a water tank water inlet valve with an integrated floating bucket structure is composed of a water inlet valve body 1 and a floating bucket working device 2. The water inlet valve body includes a base 11, a filter 12, a water inlet body 13, and a water inlet body. Core 14, water sealing rubber pad 15, water inlet upper end 16; an air port 161 is arranged at the water inlet upper end; the floating bucket working device 2 includes an outer floating bucket 21 and an inner floating bucket 22, and the inner floating bucket is an integral structure , which is composed of an inner floating barrel body 221 and a swing rod 222 as a whole. Two positioning lugs 223 extend outward on both sides of the upper end of the swing rod 222, which are connected with the water inlet upper end 16 of the water inlet valve main body 1 and serve as The fulcrum of the rocking rod realizes swinging up and down, and a rubber pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com