Assembly wood structure beam column embedded steel bar joint

A prefabricated, wooden structure technology, applied in the direction of building structure, construction, etc., can solve the problems of on-site construction difficulties, high bearing capacity, poor ductility, etc., and achieve high practical value and economic value, high bearing capacity, and good bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

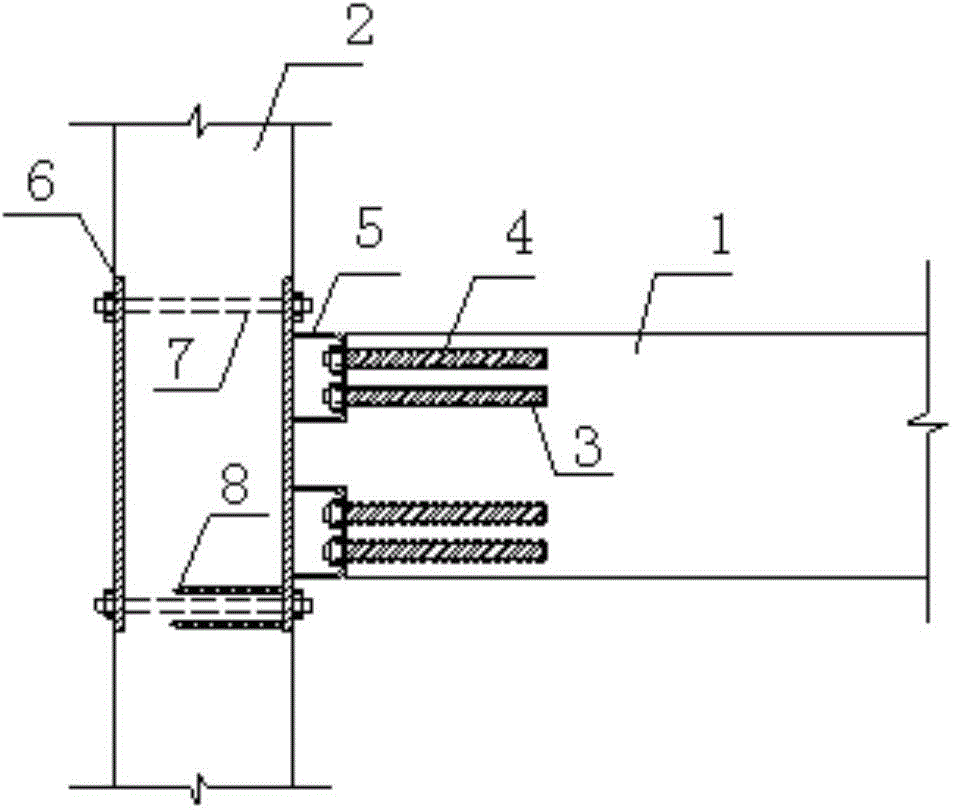

[0031] Such as figure 1 and 8 As shown, a prefabricated wood structure beam-column planting reinforcement node, including wooden beam 1, wooden column 2, planting reinforcement 3, adhesive 4, assembled connector 5, node fastener 7 and steel backing plate 6, said The wooden beam 1 and the wooden column 2 are connected by an assembled connector 5, a planting bar 3 and a node fastener 7, and the planting bar 3 is planted in the pre-drilled or reserved channel at the end of the beam through an adhesive 4 or In the opened channel, the assembled connector 5 is fixed on the column body through the node fastener 7, and the node fastener 7 is fixed on the side of the wooden column 2 facing away from the wooden beam 1 through the steel backing plate 6, and the beam end is on the The 3 parts of the planting bars are reinforced with self-tapping screws 8 for transverse grains.

[0032] The cross-sectional shape of the wooden beam 1 and the wooden column 2 is square, rectangular or circu...

Embodiment 2

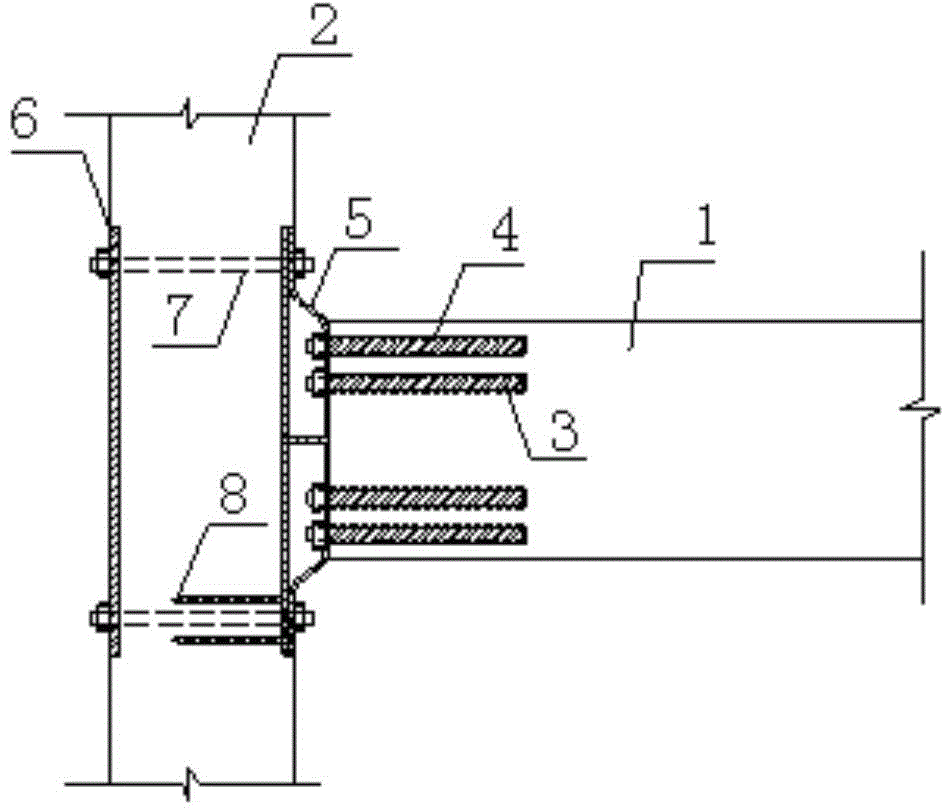

[0036] Such as figure 2 and 9 As shown, the joint structure of the prefabricated wood beam-column planting bar in this embodiment is the same as that in Embodiment 1, the difference is that the prefabricated connectors described in this embodiment are as follows Figure 6 shown.

Embodiment 3

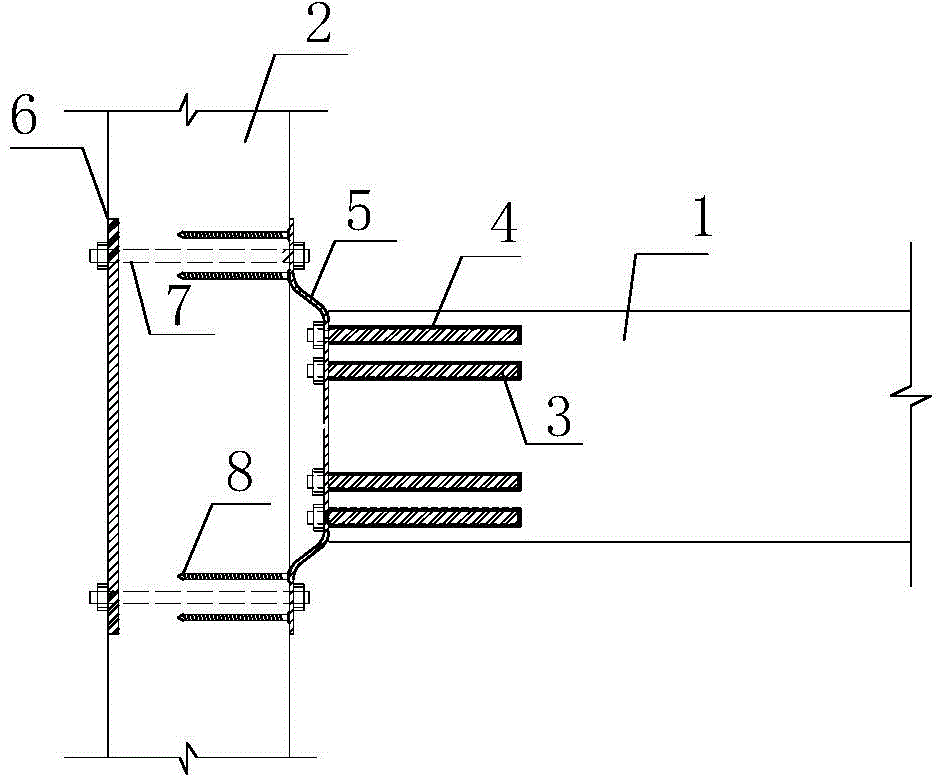

[0038] Such as image 3 and 10 As shown, the joint structure of the prefabricated wood beam-column planting bar in this embodiment is the same as that in Embodiment 1, the difference is that the prefabricated connectors described in this embodiment are as follows Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com