Silencer

A muffler and cylinder technology, applied in the direction of mufflers, machines/engines, engine components, etc., can solve problems such as unfavorable manufacturing, complex structures of resistant mufflers or impedance composite mufflers, and achieve low cost, simple structure, and good performance. The effect of the noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

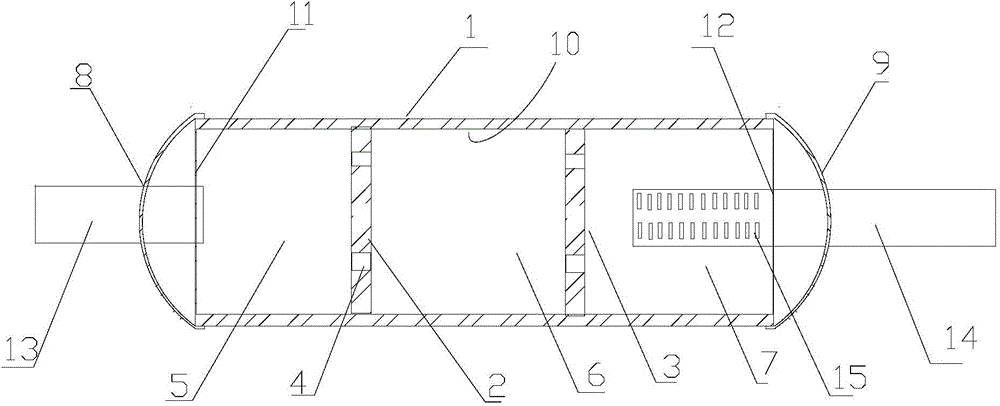

[0014] see figure 1 , a muffler, including a cylinder 1, the cylinder 1 has an air inlet end 11 and an air outlet 12; the cylinder 1 is provided with two partitions 2, 3, the outer walls of the partitions 2, 3 The rim is in sealing connection with the inner wall of the cylinder 1, and the partitions 2, 3 are provided with a plurality of airflow holes 4 along the circumference and near the outer edge, and the partitions 2, 3 connect the cylinder 1 The inner space is divided into three first spaces 5 with different volumes, a second space 6 and a third space 7. The air inlet 11 and the air outlet 12 are connected with an air inlet 13 and an air outlet 14 respectively. 14 is provided with an exhaust hole 15 on the surface of the part protruding into the interior of the cylinder bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com