High-precision non-uniformity correction method for dynamic adjustment of integration time

A non-uniformity correction and integration time technology, applied in the field of infrared imaging, can solve problems such as unsuitable correction parameters, image saturation or low response value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] A high-precision non-uniformity correction method with dynamic adjustment of integration time according to the present invention will be described in detail below with reference to the drawings and embodiments.

[0058]A high-precision non-uniformity correction method for dynamic adjustment of integration time of the present invention comprises the following steps:

[0059] step 1

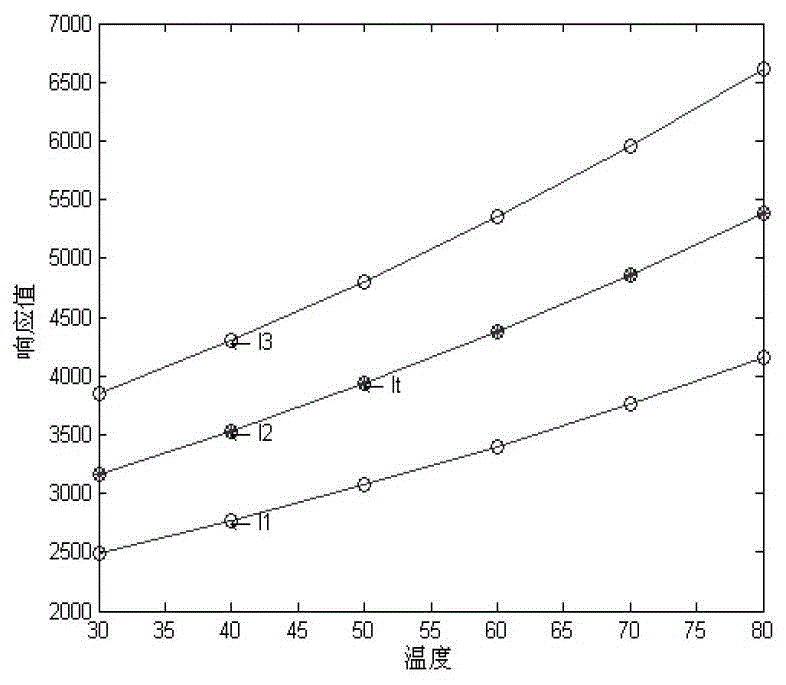

[0060] Collect the detector response value data of each integration time length at different temperatures, and generate figure 2 The temperature-response curves of the detector at different integration time lengths are shown.

[0061] In this embodiment, the collected detector response value data of each integration time length at different temperatures is shown in the following table:

[0062]

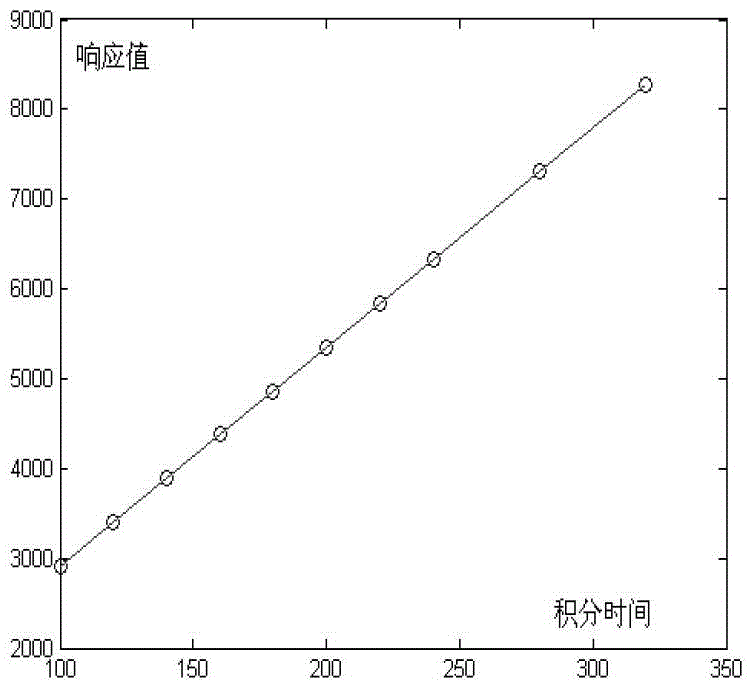

[0063] It can be seen from the above table that the detector response value and the integration time length at a fixed temperature satisfy image 3 The linear relationship shown, the linear r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com