Vacuum container sectional pressure raising quantitative leakage rate test method

A technology of vacuum container and leak rate, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the fluid's acceleration and deceleration rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

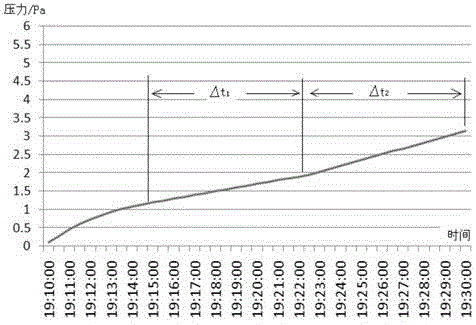

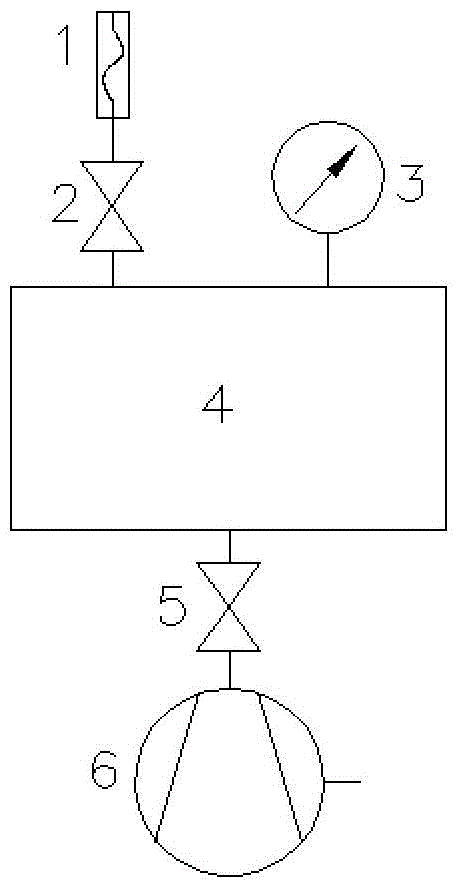

[0025] Such as figure 1 As shown, the test process of the present invention is: the passage type standard leak hole 1 is connected on the vacuum container 4 through the standard leak hole introduction valve 2, and the vacuum container 4 is connected with the vacuum gauge 3 and the vacuum system valve 5 respectively, and the vacuum pump 6 is connected with the vacuum system valve 5. Vacuum system valve 5 is connected. Close the standard introduction valve 2, open the vacuum system valve 5, run the vacuum pump 6 to evacuate the vacuum container 4, and monitor the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com