Risk-based oil refining device corrosion management control method

A management control and refining unit technology, applied in the field of risk-based corrosion management and control of oil refining units, can solve the problems of lack of intermediate process control of corrosion, unscientific and reasonable allocation of anti-corrosion resources, etc., to achieve the effect of strengthening control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

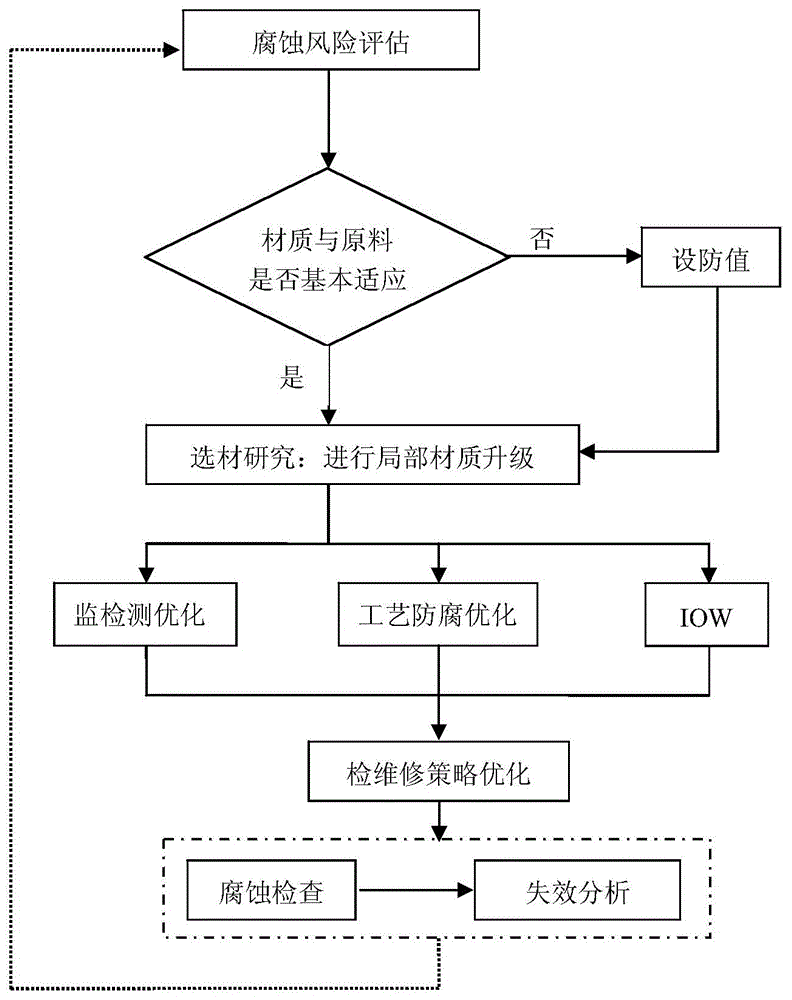

[0012] like figure 1 As shown, firstly, the corrosion circuit of the device is divided, and the corresponding mathematical model is established according to the respective corrosion mechanism, the corrosion risk assessment is carried out, and the corrosion risk is quantified. The high-temperature corrosion risk of the device basically depends on the contradiction between the material and the degree of deterioration of the raw material oil. According to the results of the corrosion assessment, it is judged whether the material of the device is basically compatible with the degree of deterioration of the processed raw oil. If the established acceptable risk standard cannot be reached through partial material upgrade, the corrosive medium will be fortified to limit the content of corrosive medium in the feedstock oil of the unit until the high temperature corrosion risk can meet the established acceptable standard after local material upgrade. Then, according to the corrosion ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com