High voltage moving magnet bidirectional proportional electromagnet

A technology of proportional electromagnet and moving magnet, which is applied to electromagnets with armatures, electromagnets, circuits, etc., can solve the problems of inability to realize proportional control and inability to work, and achieve simple structure, high output force, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

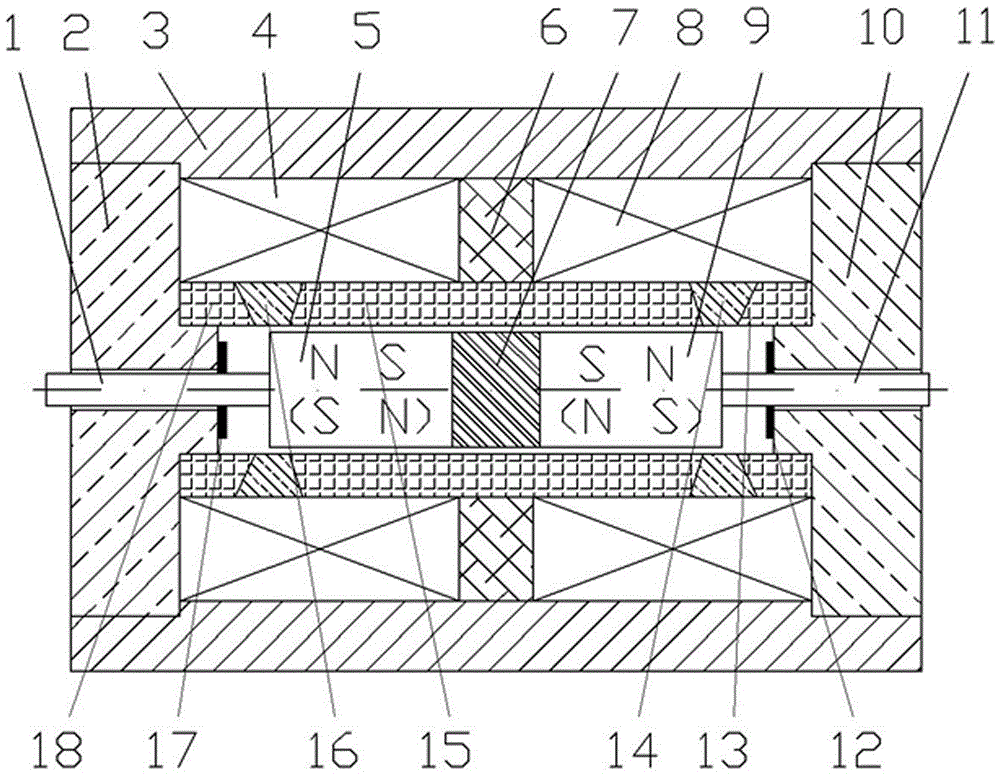

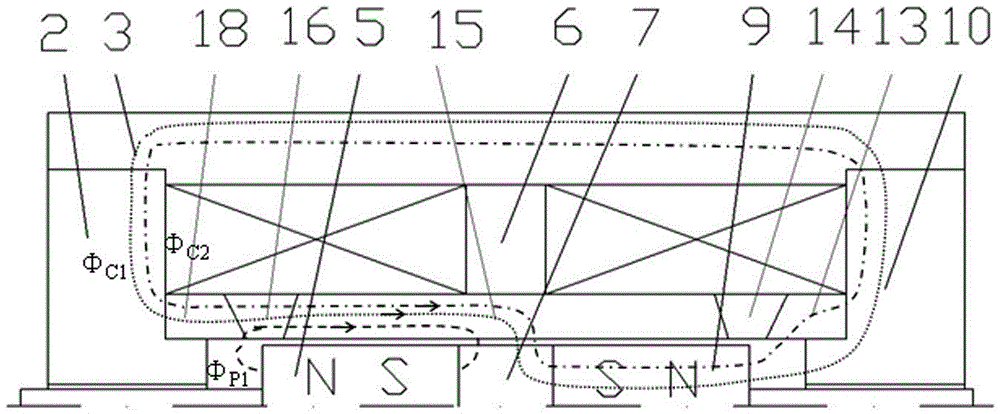

[0019] Such as Figure 1 ~ Figure 3 As shown, the high-voltage resistant moving magnet type bidirectional proportional electromagnet of the present invention includes push rods 1, 11, yoke irons 2, 10, housing 3, control coils 4, 8, first permanent magnet 5, magnetic conduction ring 6, Armature 7, the second permanent magnet 9, limit pieces 12,17, guide sleeves 13,15,18, magnetic isolation rings 14,16. The housing 3, the yokes 2, 10, the armature 7, and the guide sleeves 13, 15, 18 are all magnetizers.

[0020] The shell 3 is a hollow shell, the two ends are connected with the yokes 2, 10, the flanges of the yokes 2, 10 are matched with the inner holes of the guide sleeves 13, 15, 18, and the guide sleeves 13, 15, 18 are non-guided The magnetic isolation rings 14 and 16 made of magnetic material are separated and welde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com