Semi-automatic Wafer Ball Mounting Equipment

A semi-automatic, wafer-based technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as operational errors, high prices, low efficiency, etc., to ensure accuracy and speed, low maintenance costs, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

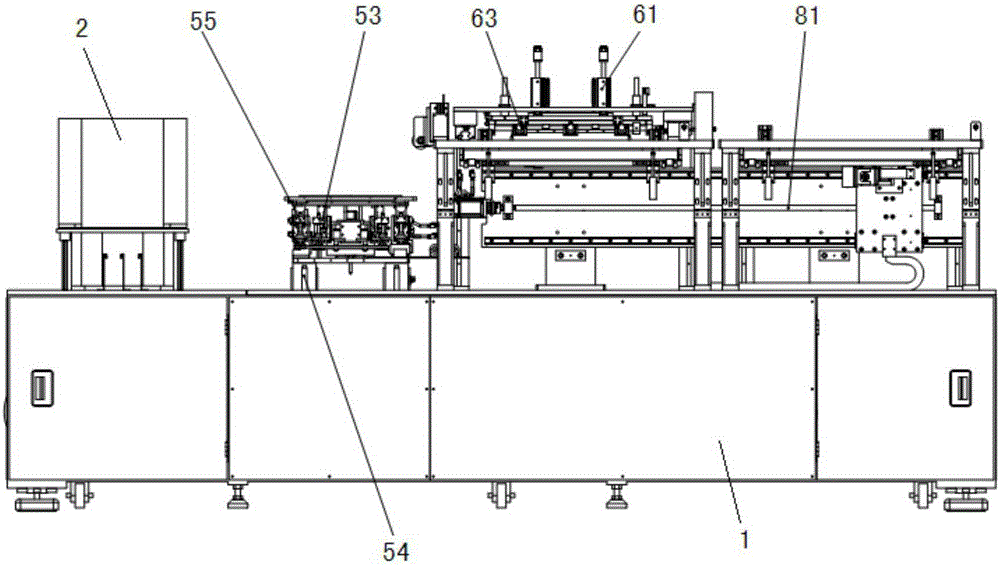

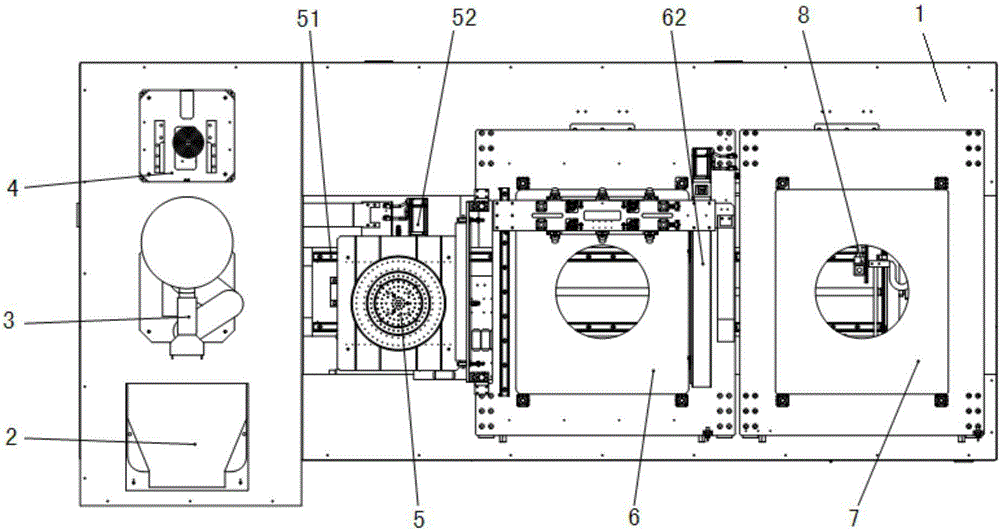

[0021] see figure 1 , figure 2 , the semi-automatic wafer ball planting equipment of the present invention comprises a bottom stand 1, on which a wafer loading / unloading mechanism 2, a wafer transfer manipulator 3, a wafer calibration mechanism 4, a wafer loading platform 5, a wafer Circular printing mechanism 6, wafer ball planting mechanism 7 and CCD alignment system 8. Wafer loading / unloading mechanism 2, wafer transfer manipulator 3 and wafer alignment mechanism 4 are sequentially arranged at one end of bottom stand 1 along the y-axis direction, wafer loading stage 5, wafer printing mechanism 6, wafer ball planting The mechanism 7 and the CCD alignment system 8 are sequentially arranged on the bottom platform along the x-axis direction, and the wafer loading platform 5 is arranged adjacent to the wafer transfer robot 3, and the wafer ball planting mechanism 7 and the CCD alignment system 8 are combined and adjacent A wafer printing mechanism 6 is provided.

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com