Staggered parallel-connection direct-current voltage reduction converter with phase-by-phase coupled inductor

A DC step-down and converter technology, applied in the direction of converting DC power input to DC power output, adjusting electrical variables, output power conversion devices, etc., can solve the problem of affecting the efficiency and dynamic performance of the converter, and restricting the miniaturization of the converter, etc. problems, to achieve the effect of increasing control stability, improving dynamic response and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples, but the protection scope of the present invention is not limited to the following implementation examples.

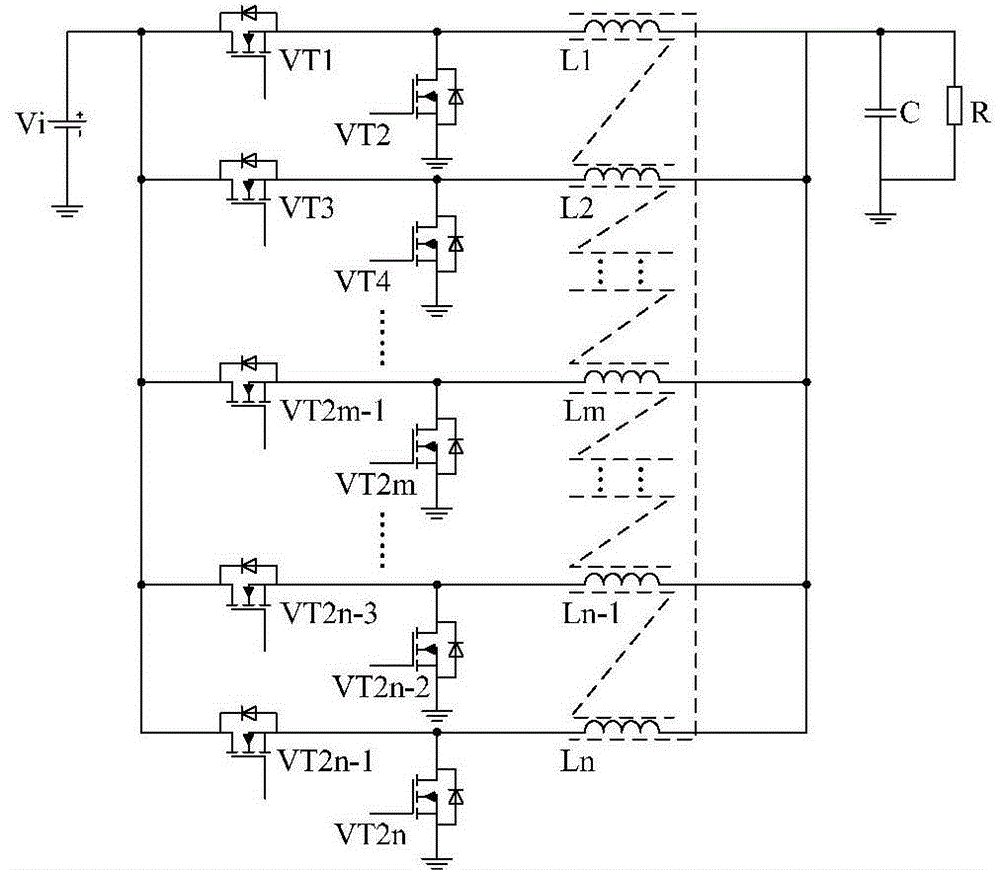

[0014] figure 1 It shows an interleaved parallel DC step-down converter with inductance phase-by-phase coupling of the present invention. The n-phase interleaved parallel DC step-down converter includes 2n power switch tubes VT1, VT2...VT2n, a filter capacitor C, and a The coupled inductance of n windings L1, L2...Ln, the winding of the coupled inductance is that the L1 winding is coupled with the L2 winding, the L2 winding is coupled with the L3 winding, and so on, the Ln-1 winding is coupled with the Ln winding, and the Ln winding is coupled with the L1 winding Coupling; and the Lm (1<m<n) winding is only coupled to the Lm-1 winding and Lm+1 winding, but not to other phases, the L1 winding is only coupled to the L2 winding and the Ln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com