Impregnated calcium carbonate, method for producing same, polymer composition, and polymer precursor composition

一种碳酸钙、聚合物的技术,应用在碳酸钙/锶/钡、用于材料和表面科学的纳米技术、纤维状填料等方向,能够解决操作困难、碳酸钙易飞散等问题,达到分散性优异、不易飞散、操作容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0111] To BET specific surface area is 20m 2 2 kg of synthetic calcium carbonate / g was heated with water so that the solid content was 10% by weight, and a calcium carbonate slurry liquid was prepared using a stirring type disperser. While stirring the slurry liquid with a disperser, 60 g of sodium stearate was added, and the mixture was further stirred for 5 minutes. Next, the obtained slurry was dehydrated with a filter press, and then dried and powdered with a box dryer to obtain about 2 kg of surface-treated calcium carbonate surface-treated with sodium stearate.

[0112] Next, 200 g of the obtained surface-treated calcium carbonate was put into a mixer (flow mixer SMP-2 manufactured by Kawata Co., Ltd.), and stirred. Next, 10 g of Diana Process Oil NP-24 (trade name) produced by Idemitsu Kosan Co., Ltd., which is a naphthenic mineral oil, was sprayed into the mixer and stirred to obtain impregnated calcium carbonate. The treatment amount of Diana Process Oil NP-24 was a...

Embodiment 2)

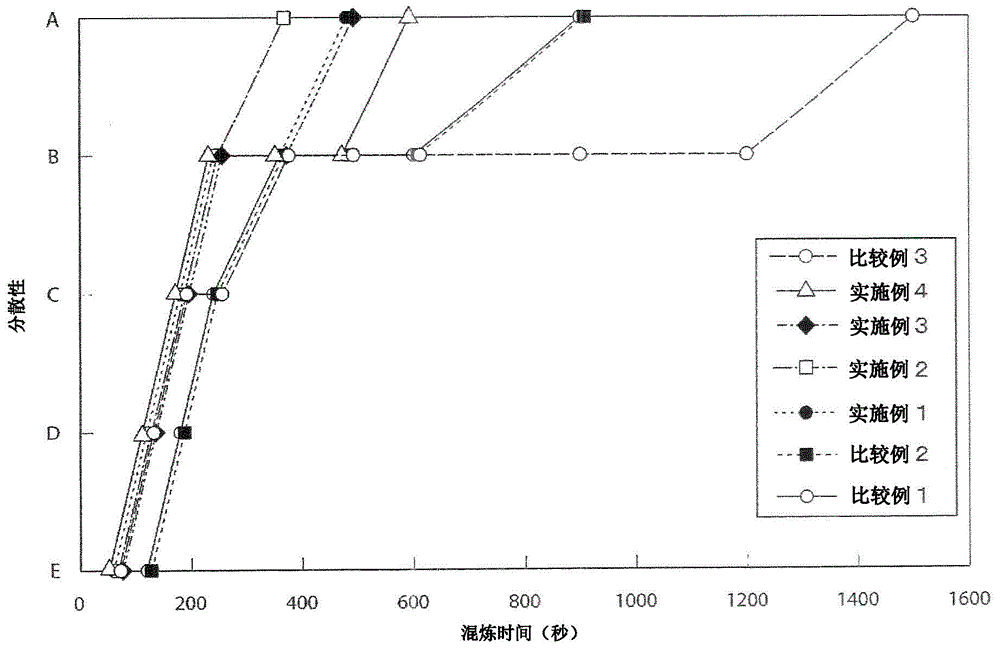

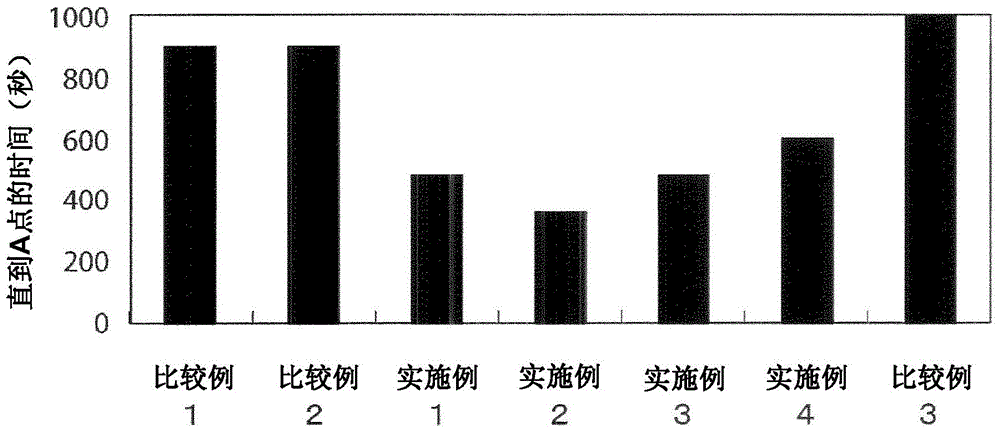

[0123] An impregnation-treated calcium carbonate was obtained in the same manner as in Example 1, except that the amount of Diana Process Oil NP-24 (trade name) was 10 parts by weight with respect to 100 parts by weight of the surface-treated calcium carbonate. Next, similarly to Example 1, the scattering property (dispersion degree) of the impregnated calcium carbonate obtained in Example 2 was evaluated. The results are shown in Table 1 below. Next, in the same manner as in Example 1, the impregnated calcium carbonate obtained in Example 2 and the resin were mixed to prepare a resin paste, and the dispersibility of the impregnated calcium carbonate in the obtained resin paste was evaluated. The ratio of the compounding quantity of each component contained in the resin paste to which the impregnation-treated calcium carbonate was added is shown in Table 2. The evaluation results of dispersibility are shown in Table 4, figure 2 and image 3 middle.

Embodiment 3)

[0125] An impregnation-treated calcium carbonate was obtained in the same manner as in Example 1, except that the amount of Diana Process Oil NP-24 (trade name) was 14 parts by weight relative to 100 parts by weight of the surface-treated calcium carbonate. Next, similarly to Example 1, the scattering property (dispersion degree) of the impregnated calcium carbonate obtained in Example 3 was evaluated. The results are shown in Table 1 below. Next, in the same manner as in Example 1, the impregnated calcium carbonate obtained in Example 3 and the resin were mixed to prepare a resin paste, and the dispersibility of the impregnated calcium carbonate in the resin paste was evaluated. The ratio of the compounding quantity of each component contained in the resin paste to which the impregnation-treated calcium carbonate was added is shown in Table 2. The evaluation results of dispersibility are shown in Table 4, figure 2 and image 3 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com