Table type single-ear wheat threshing machine

A thresher, single-ear technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems affecting wheat germination rate, survival rate, high threshing rotation intensity, damage to wheat germ parts, etc., to ensure the germination rate. and survival rate, avoid damage, increase the effect of force friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the technical content of the present invention, it will be further described below in conjunction with the accompanying drawings.

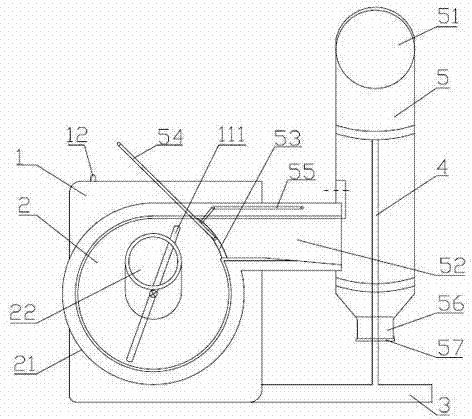

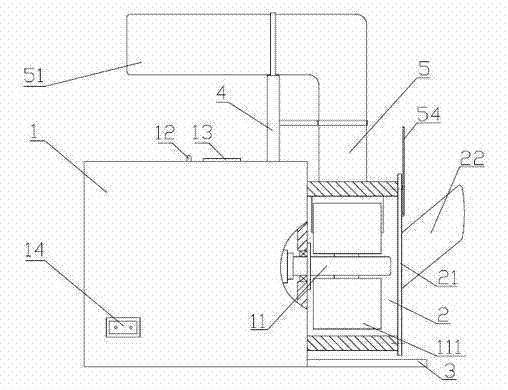

[0029] Such as figure 1 with figure 2 As shown, a desktop single-ear wheat thresher includes a motor box 1 with a motor fixed thereon, a threshing bin 2 fixed on the front end of the motor box 1, and a base 3 arranged at the lower end of the motor box 1. And the fixed bracket 4 fixed on the base 3.

[0030] A start switch 12 , a control panel 13 and a power connection port 14 are arranged on the motor case 1 , and the start switch 12 is responsible for controlling the power-on operation of the motor. The control panel 13 is used to control the rotation speed and direction of the motor, but is not limited thereto. The motor is arranged in the motor case 1 along the front-rear direction, that is, the axial direction of the motor shaft 11 is the front-rear direction.

[0031] The inner cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com