Frost prevention smoke bomb

A pod and frost-proof technology, applied in the fields of gardening, application, and botanical equipment and methods, can solve the problems of inconvenient ignition, unstable combustion, and unsatisfactory smoke concentration, and achieve easy ignition, labor saving, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

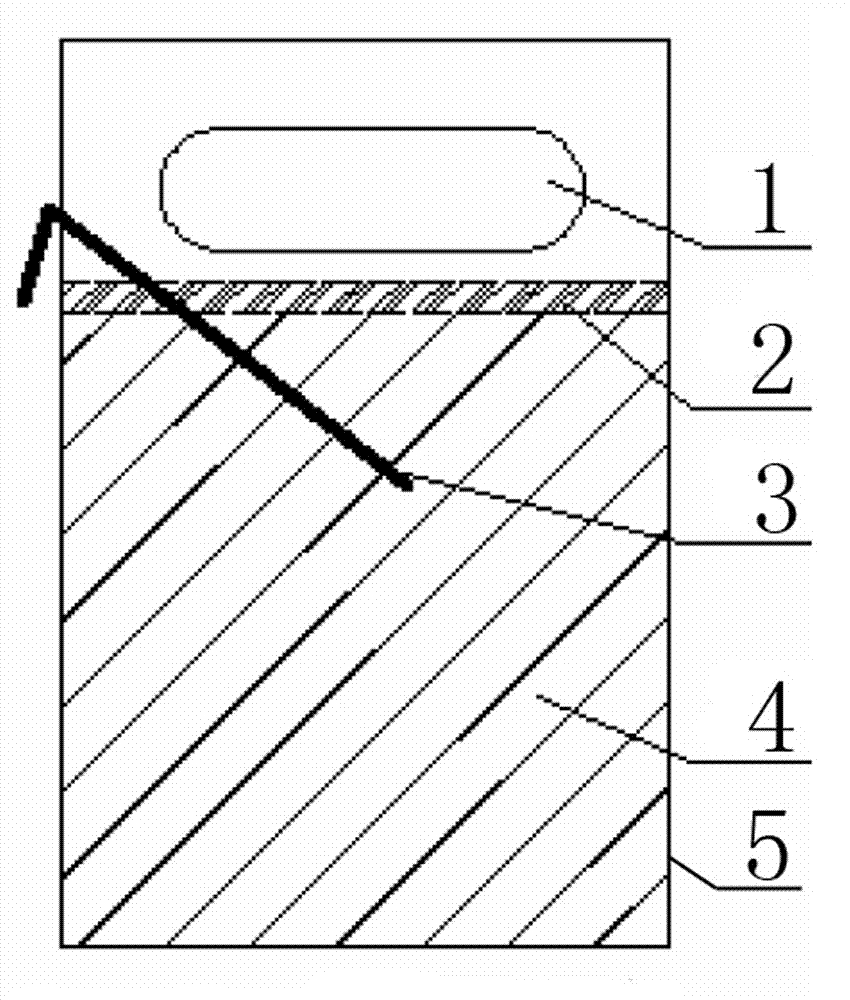

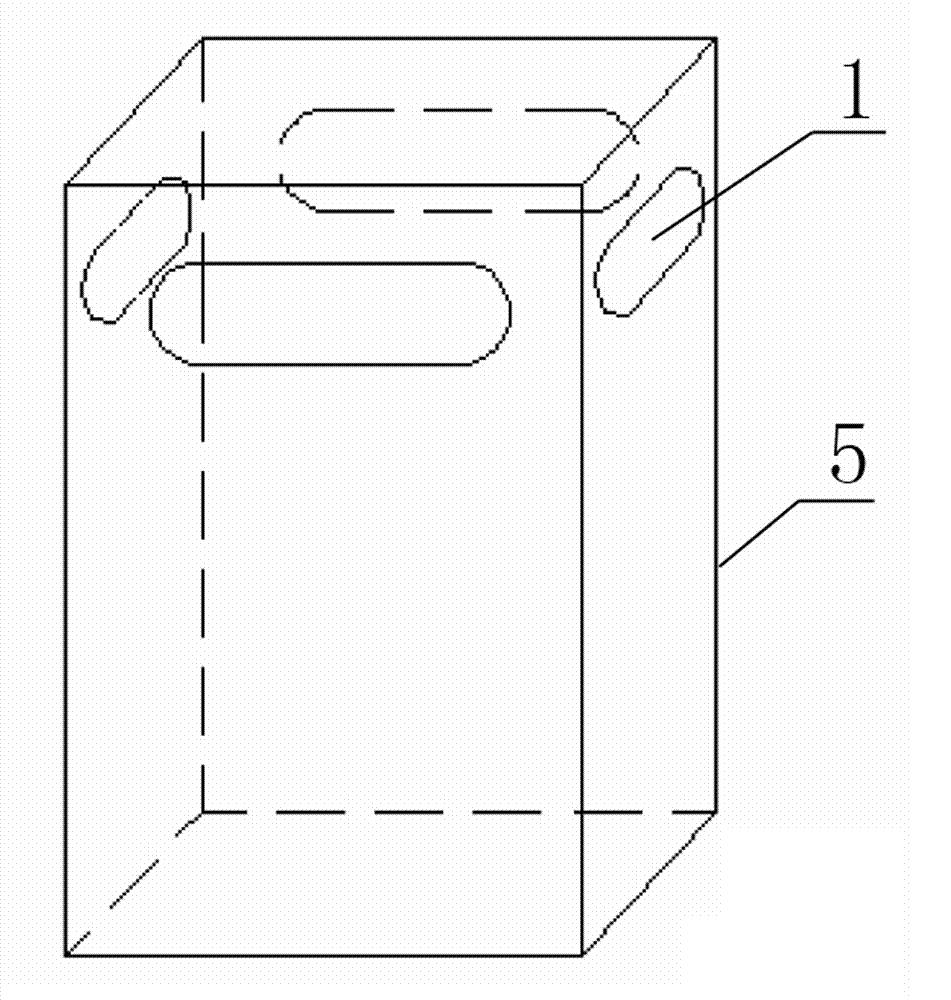

[0013] Example 1 by figure 1 and figure 2 It can be seen that the anti-frost pod includes the fuse 3, the ignition material 2, the smoking material 4 and the outer packaging 5, the smoking material 4 and the ignition material 2 are located inside the outer packaging 5, and the ignition material 2 is set On the top of the smoking material 4, one end of the fuse 3 is located outside the outer packaging 5, and the other end extends into the inside of the smoking material 4 through the ignition material 2, and the outer packaging 5 is provided with a smoke outlet 1, wherein the formula of the smoking material is as follows The weight ratio is, sawdust: potassium nitrate: white sugar: charcoal powder = 30:15:10: 3; the ignition material formula is in weight ratio, sawdust: potassium nitrate: white sugar: charcoal powder = 30:20:10:3; The ratio of smoke material to ignition material is 40:1 by weight.

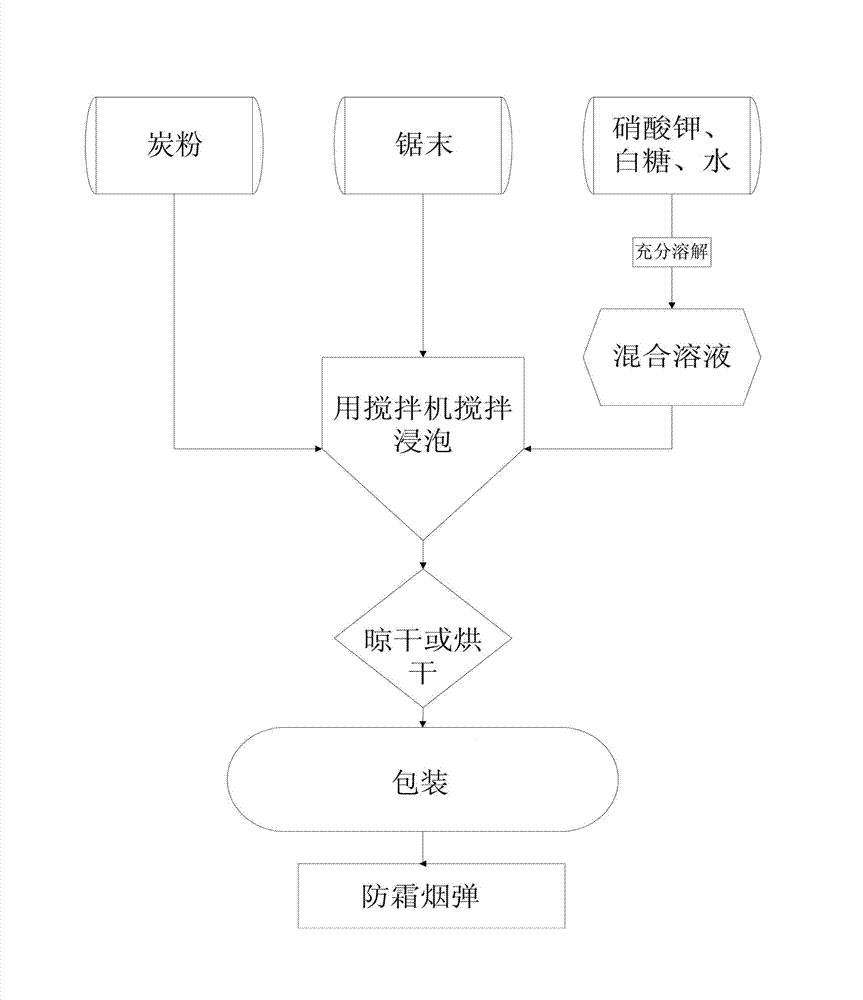

[0014] Depend on image 3 It can be seen that the manufacturing method of th...

Embodiment 2

[0016] Example 2 by figure 1 and figure 2 It can be seen that the anti-frost pod includes the fuse 3, the ignition material 2, the smoking material 4 and the outer packaging 5, the smoking material 4 and the ignition material 2 are located inside the outer packaging 5, and the ignition material 2 is set On the top of the smoking material 4, one end of the fuse 3 is located outside the outer packaging 5, and the other end extends into the inside of the smoking material 4 through the ignition material 2, and the outer packaging 5 is provided with a smoke outlet 1, wherein the formula of the smoking material is as follows The weight ratio is, sawdust: potassium nitrate: white sugar: charcoal powder=15: 6: 4: 1; the ignition material formula is by weight ratio, sawdust: potassium nitrate: white sugar: charcoal powder=15: 10: 4: 1; The ratio of smoke material to ignition material is 10:1 by weight.

[0017] The manufacturing method of the anti-frost pod is the same as in Example...

Embodiment 3

[0018] Example 3 by figure 1 and figure 2 It can be seen that the anti-frost pod includes the fuse 3, the ignition material 2, the smoking material 4 and the outer packaging 5, the smoking material 4 and the ignition material 2 are located inside the outer packaging 5, and the ignition material 2 is set On the top of the smoking material 4, one end of the fuse 3 is located outside the outer packaging 5, and the other end extends into the inside of the smoking material 4 through the ignition material 2, and the outer packaging 5 is provided with a smoke outlet 1, wherein the formula of the smoking material is as follows The weight ratio is, sawdust: potassium nitrate: white sugar: charcoal powder = 25:8:6: 3; the ignition material formula is according to the weight ratio, sawdust: potassium nitrate: white sugar: charcoal powder = 25:15:6:3; The weight ratio of smoke material to ignition material is 25:1.

[0019] The manufacturing method of anti-frost smoke bomb adopts the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com