Rotary barrel type sewage precipitator with inclined plate

A technology of rotating drum and arc plate, applied in the direction of separating sediments by centrifugal force, etc., can solve the problems such as the impact load of water volume and the adaptability of water temperature changes in inclined tube sedimentation tanks, the inability to eliminate sedimentation stagnant areas, and affect the sedimentation effect, etc. Achieve the effect of eliminating the sedimentation retardation area, improving the clarification effect and increasing the sedimentation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

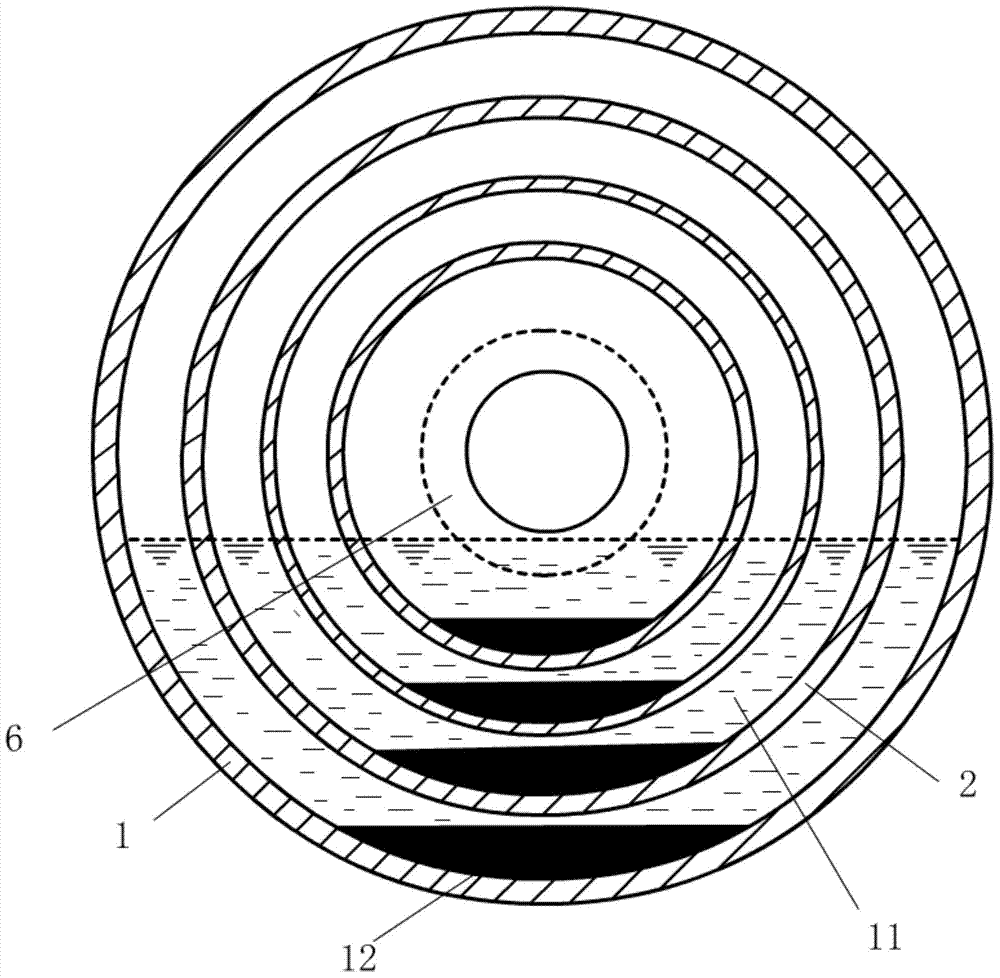

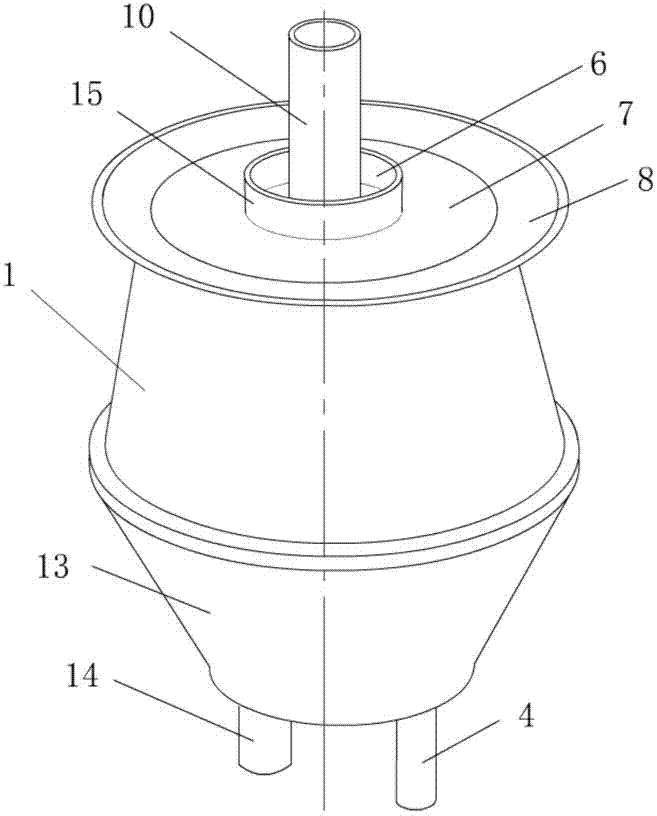

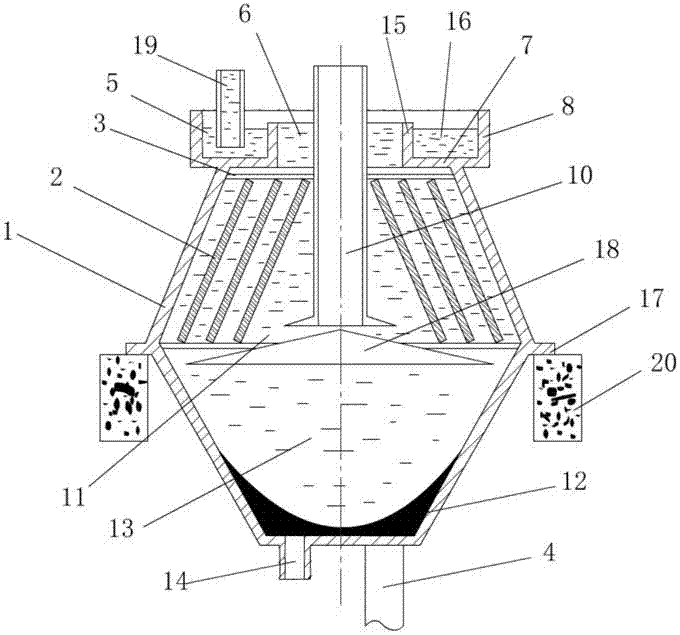

[0043] exist figure 1 In the shown embodiment, the horizontal rotary drum sewage precipitator (1) with sloping plate of the present invention is eccentrically connected with the rotating shaft (4). 1. The circular table-shaped arc plates (2) arranged overlappingly, the axis of the arc plate group (2) is parallel to the axis of the rotating cylinder (1). The cylinder wall of the circular platform and the arc plate of the circular platform are arranged parallel to each other, and are fixed inside the pool body parallel to each other with the right low and the left high. Adjacent arc plates, cylinder walls and arc plates form several inclined tube structures in the axial direction, which are lower on the right and higher on the left.

[0044] Raw water (11) flows in from the water inlet pipe (10) on the right side of the pool body, moves to the left, overflows from the water outlet (6) on the left side, enters the drainage tank (9), and is transported to the next process.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com