Agitating pot for ore dressing

A technology of stirring tank and stirring shaft, which is applied in the direction of mixer accessories, mixer with rotating stirring device, dissolving, etc. It can solve the problems of poor mineral processing quality, affecting the full mixing reaction of ore pulp and mineral processing medicine, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

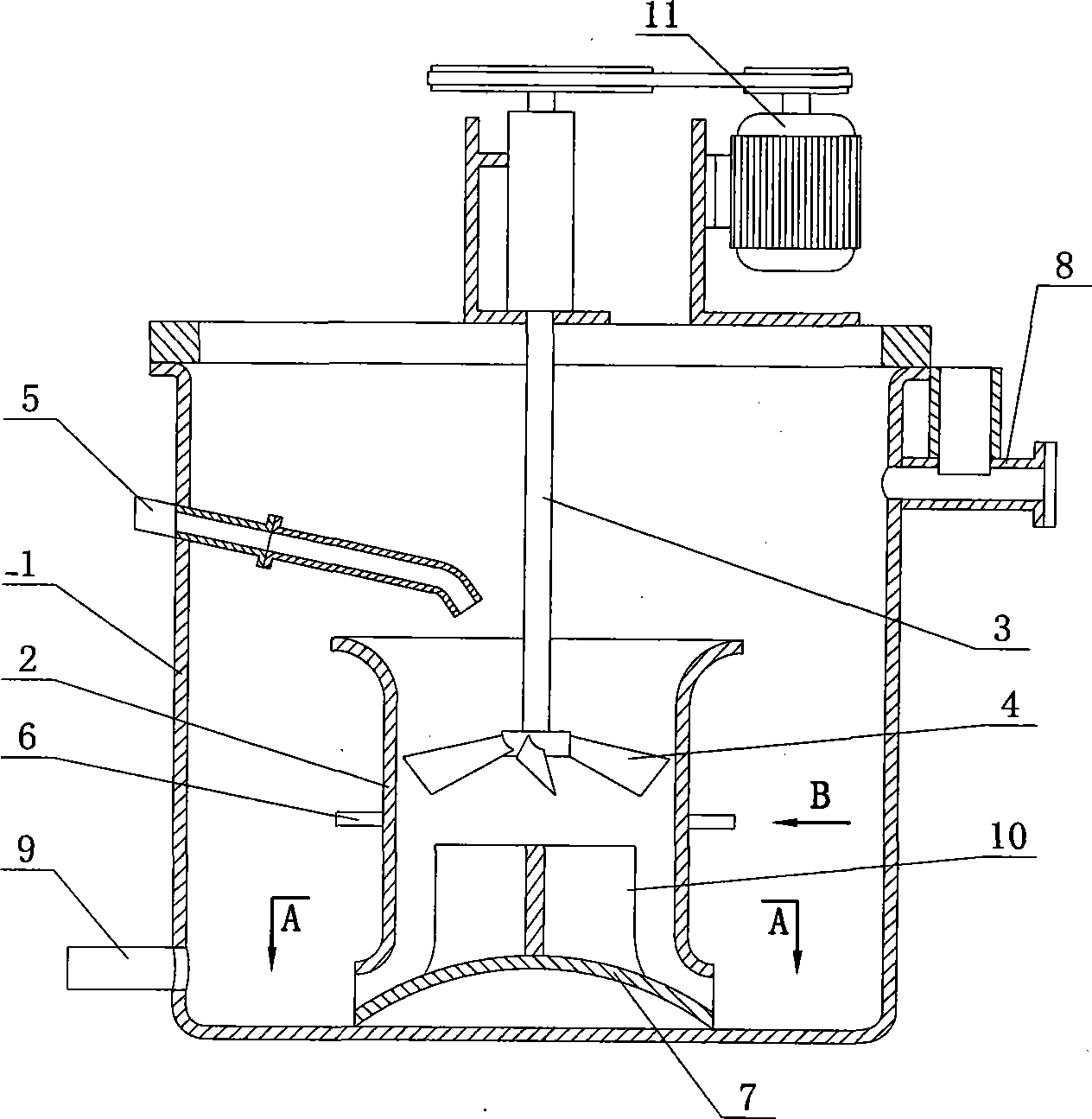

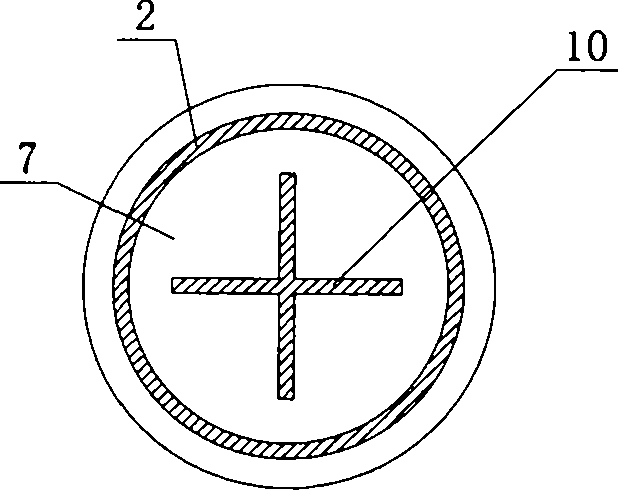

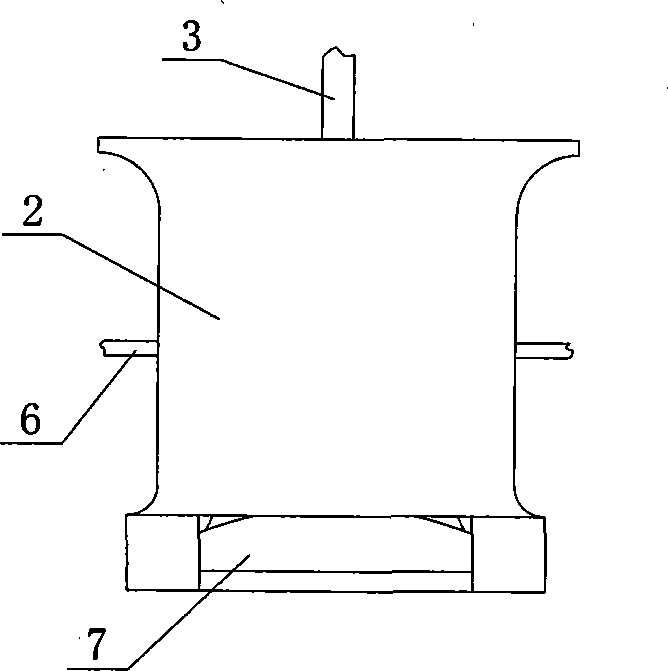

[0013] Such as figure 1 The mineral dressing stirring tank shown comprises a stirring tank body 1 with a bottom seal and an open top, and a dispersion cylinder 2 is connected in the stirring tank body 1, and the top opening and the bottom of the dispersion cylinder 2 are provided with a discharge port. The tank body 1 is rotatably connected with a stirring shaft 3 driven by a power unit and extending into the dispersion cylinder 2 at the bottom. The top of the shaft is rotatably connected on the support frame and connected with the power output shaft of the motor 11. The stirring shaft 3 is connected with a plurality of stirring blades 4, and the stirring blades 4 are ring-distributed on the stirring shaft 3 and its shape and installation method are similar to those of the fan. The blades are basically the same, that is, a plurality of stirring blades 4 are all obliquely connected to the stirring shaft 3 in the same direction, and the side wall of the stirring tank 1 is also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com