Transverse steel moving and billet discharging device

A blanking device and a steel-moving technology, which is applied in the field of horizontal steel-moving blanking devices, can solve problems such as unsatisfactory and inflexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the purpose of the present invention, the structure and function of the device for laterally moving steel and billet ejection according to the present invention will be described in detail below in combination with the background of the present invention, drawings and actual working conditions.

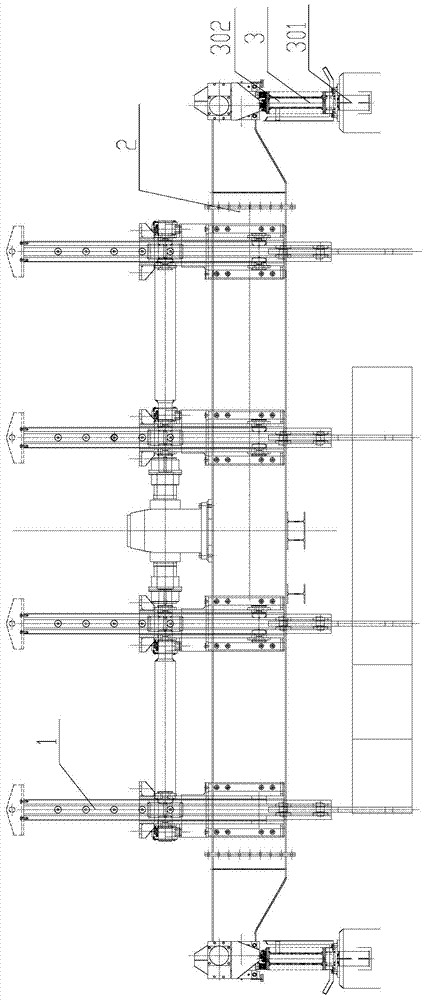

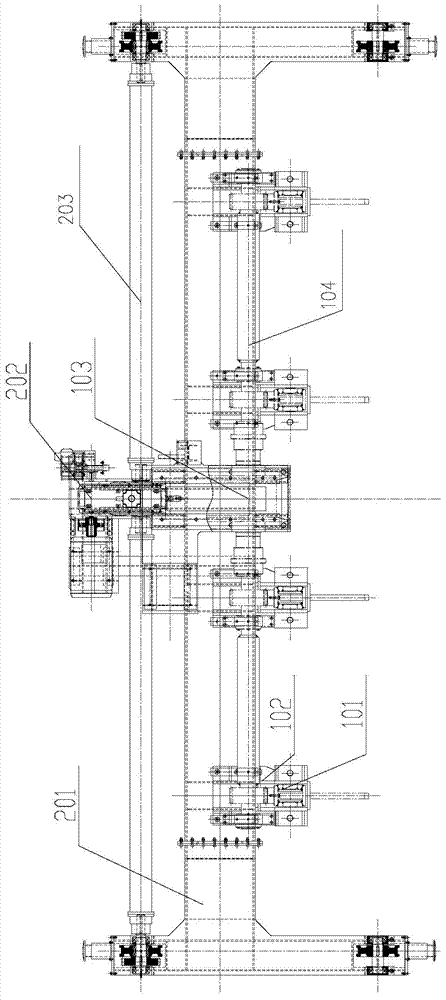

[0020] figure 1 and figure 2 They are respectively the front structural schematic diagram and the top view structural schematic diagram of the laterally moving steel blanking device of the present invention. It can be seen from the figure that the device for laterally moving steel billets of the present invention mainly includes a supporting walking beam device 3 , a laterally moving frame device 2 , and a lifting mechanism 1 .

[0021] The supporting walking beam device 3 can be fixed on the civil foundation through several supporting supports 301, and the supporting supports 301 are equipped with two parallel running beams 302; The track and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com