Caterpillar band

A crawler and pattern block technology, applied in the field of crawler, can solve the problems of gripping ability in mud and snow, in-situ cornering performance of driving performance, and poor wear resistance of patterns, and achieves convenient and flexible application, small circumferential stretch, and reduced Effect of small elongation stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

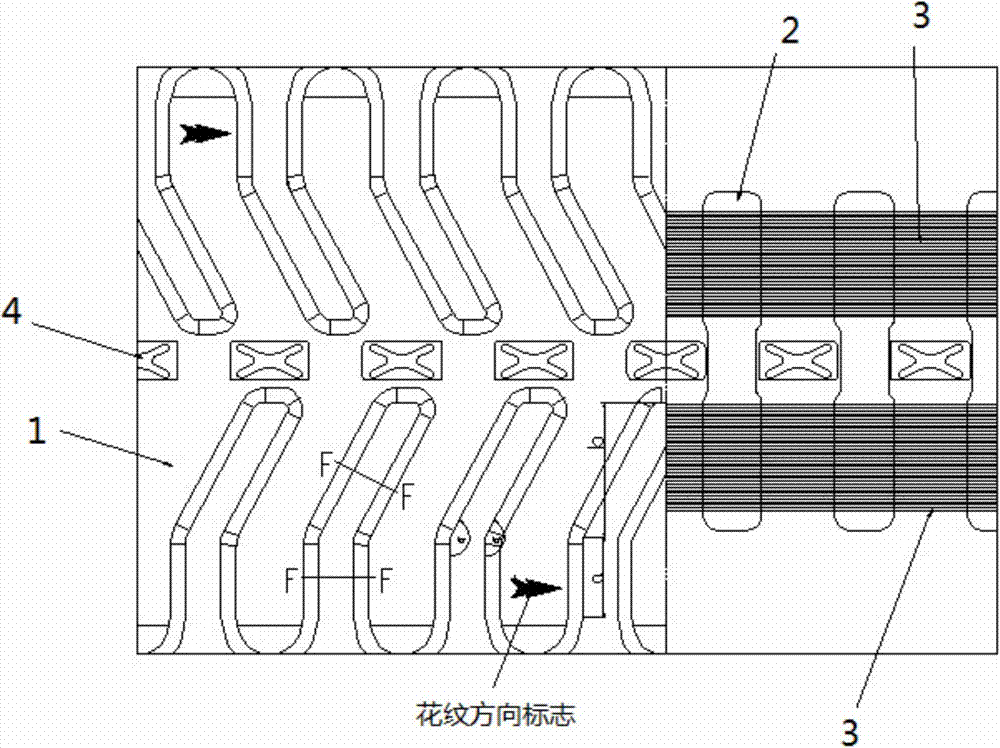

[0026] A crawler, comprising a crawler body 1, the outer surface of the crawler body 1 is provided with pattern blocks, the pattern blocks are arranged staggered along the length direction of the crawler, with driving patterns on both sides and directional guiding patterns in the middle.

Embodiment 2

[0028] A crawler belt, the same as the embodiment 1, the difference is that the inner surface of the crawler track body 1 is provided with iron teeth 2 .

Embodiment 3

[0030] A crawler, the same as the embodiment 2, the difference is that the inner surface of the crawler body 1 is flatly provided with a tensile framework 3 in the middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com