Automobile chassis part weight reduction method based on multi-body dynamics and topological optimization technology

A technology of multi-body dynamics and topology optimization, applied in the fields of mechanical and vehicle engineering, to achieve high reliability and shorten the development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific drawings.

[0030] The main purpose of the present invention is to analyze the current status of automobile design and find that there is a lack of clear and feasible lightweight methods in the current automobile design, and there is still a problem of large room for weight reduction in automobile chassis parts. Body dynamics technology and topology optimization technology of automobile chassis parts lightweight methods to solve the above problems.

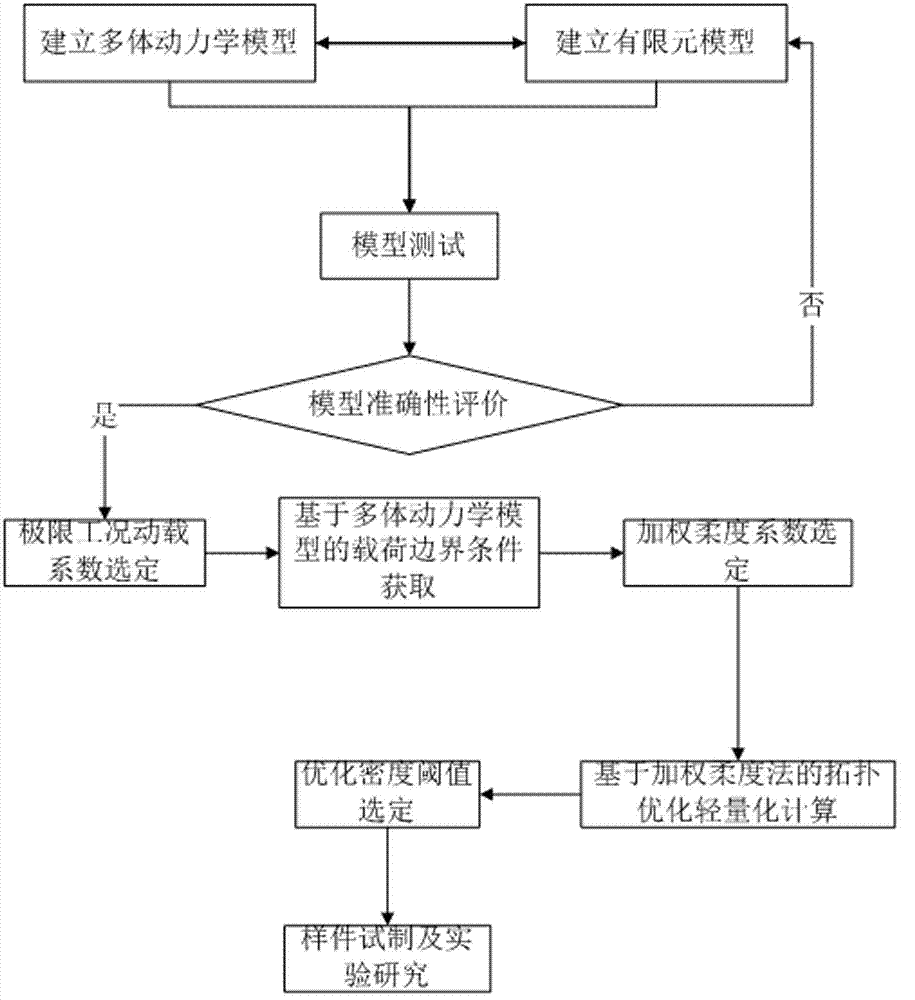

[0031] See figure 1 , The lightweight method of automobile chassis parts based on multi-body dynamics technology and topology optimization technology of the present invention includes the following steps:

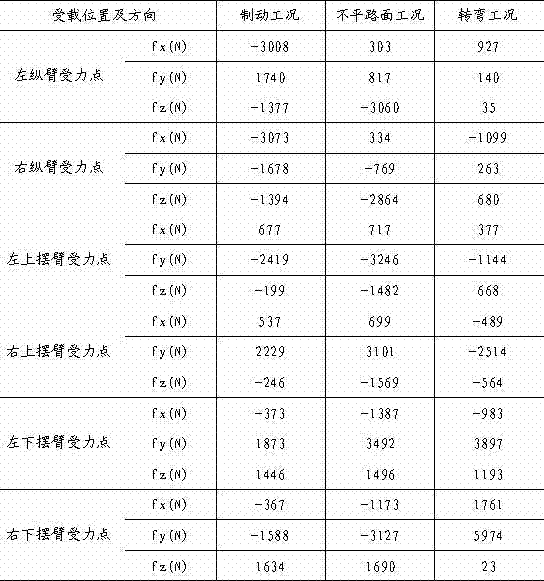

[0032] 1. Establish the vehicle multi-body dynamics model of the lightweight target model and the finite element model of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com