Winch hydraulic control system and engineering machinery

A technology of hydraulic control system and winch motor, which is applied in the direction of winch device, mechanical equipment, clockwork mechanism, etc., which can solve the problems of safety hazard, winch brake delay, winch brake can not be closed in time, etc., to prevent Safety accidents and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

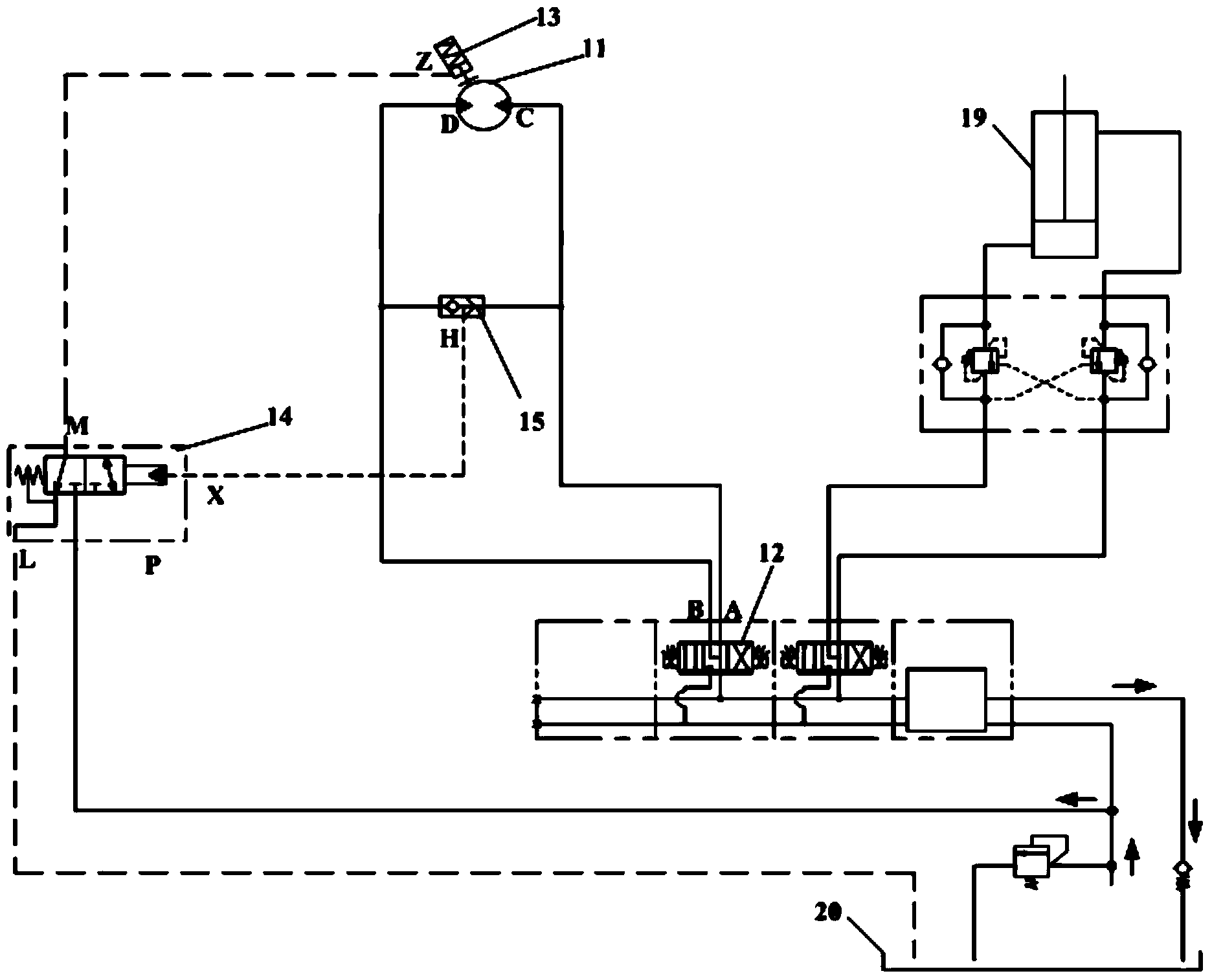

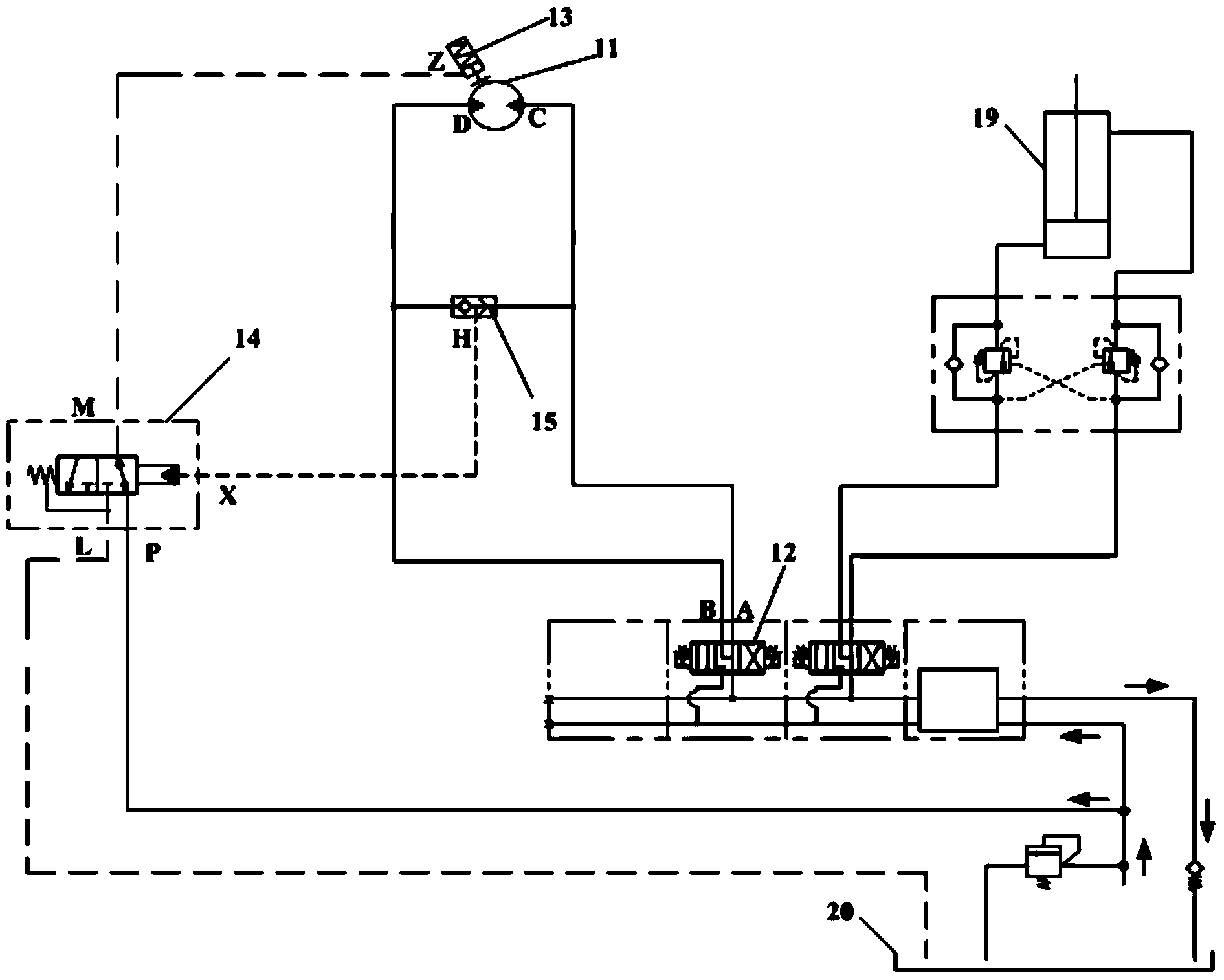

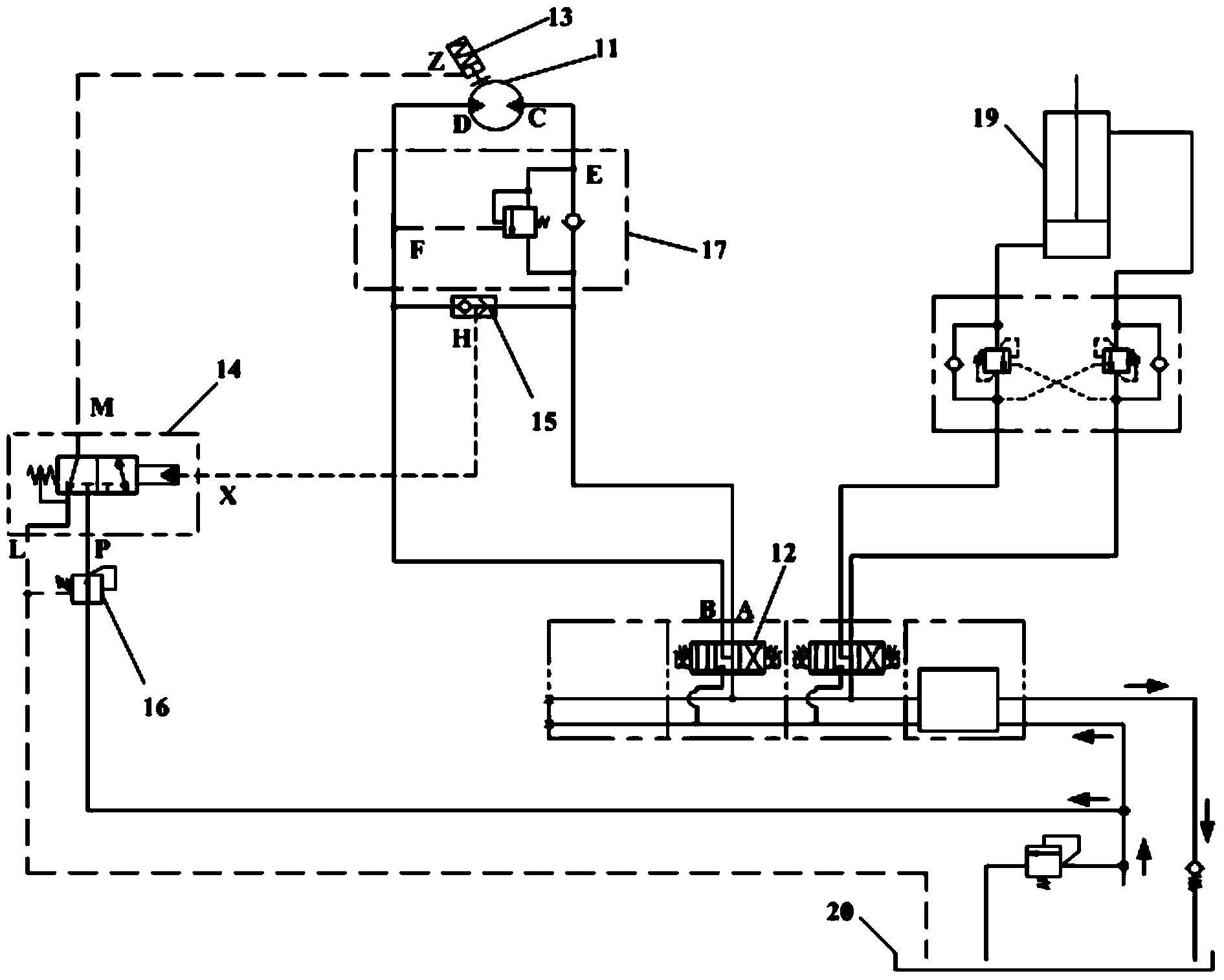

[0029] In order to improve the safety of the operation of the winch mechanism in construction machinery, and effectively prevent the occurrence of safety accidents caused by heavy objects or ladder frame sliding when the winch brakes, the embodiment of the present invention provides a winch hydraulic control system and construction machinery . In this technical scheme, when the oil pressure at the control oil port of the hydraulic control directional valve is greater than the working pressure set by the hydraulic control directional valve, The first working position is switched to the second working position where its working oil port communicates with the drain port of the hydraulic control reversing valve. Therefore, the working pressure of the hydraulic control reversing valve is set to be greater than the back pressure in the system oil return line. When the hoist motor stops running, the hydraulic control reversing valve is in the first working position where the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com