Continuous functional fiber bundle air flow scattering and forming method and equipment thereof

A technology of functional fibers and forming methods, applied in textiles, papermaking, yarns, etc., can solve the problems of clogging the output port, not setting air flow channels, yarn swelling, etc., and achieve easy deposition, high density, and easy carburization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

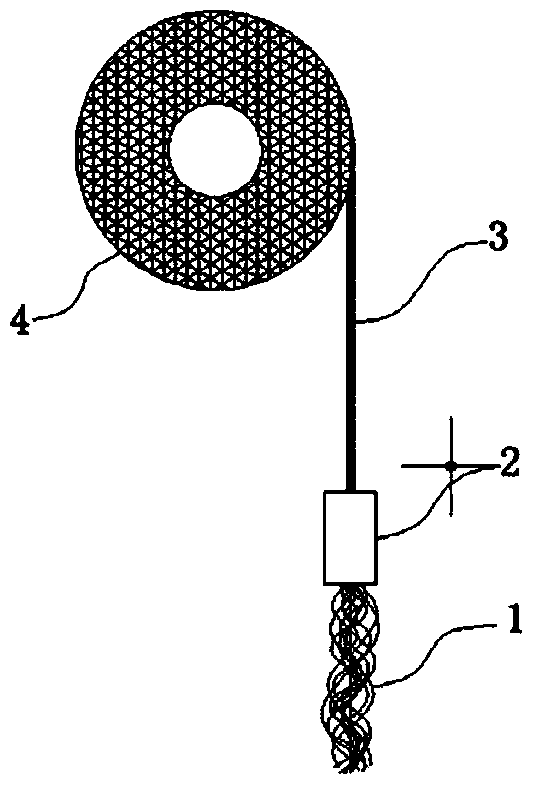

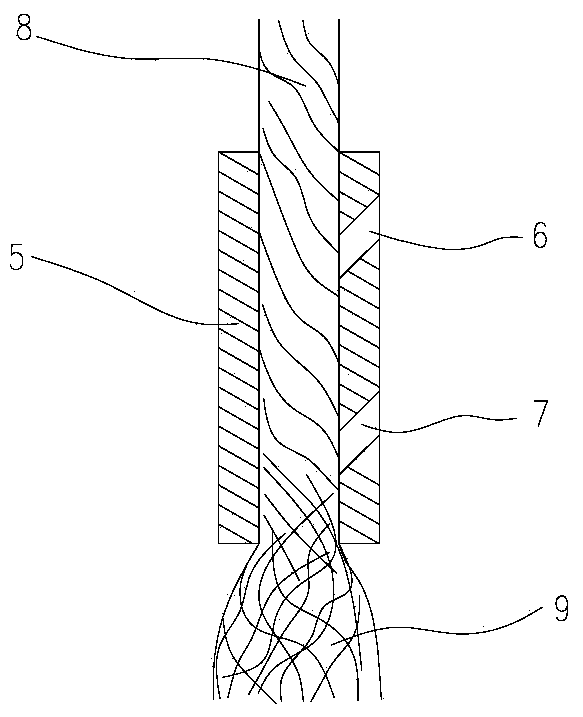

[0032] (1) Through the high-speed air puffing device, let the high-speed air flow continuously blow the functional fiber long yarn bundles, and control the airflow speed and blowing direction of the puffing device to fully separate each single yarn to form a bulky or spiral continuous fiber bundle .

[0033] (2) By adjusting the blowing speed and blowing angle, two basic types of bulked yarns can be made, namely bulky type and spiral type. The preparation of bulked yarns with different specifications can be realized by adjusting the air flow flowing into the air hole; by designing the angle of the air hole to vary between 15° and 75°, different angles of bulkers can be processed for selection. Preferably, the preparation of bulky and helical bulked yarns can be achieved.

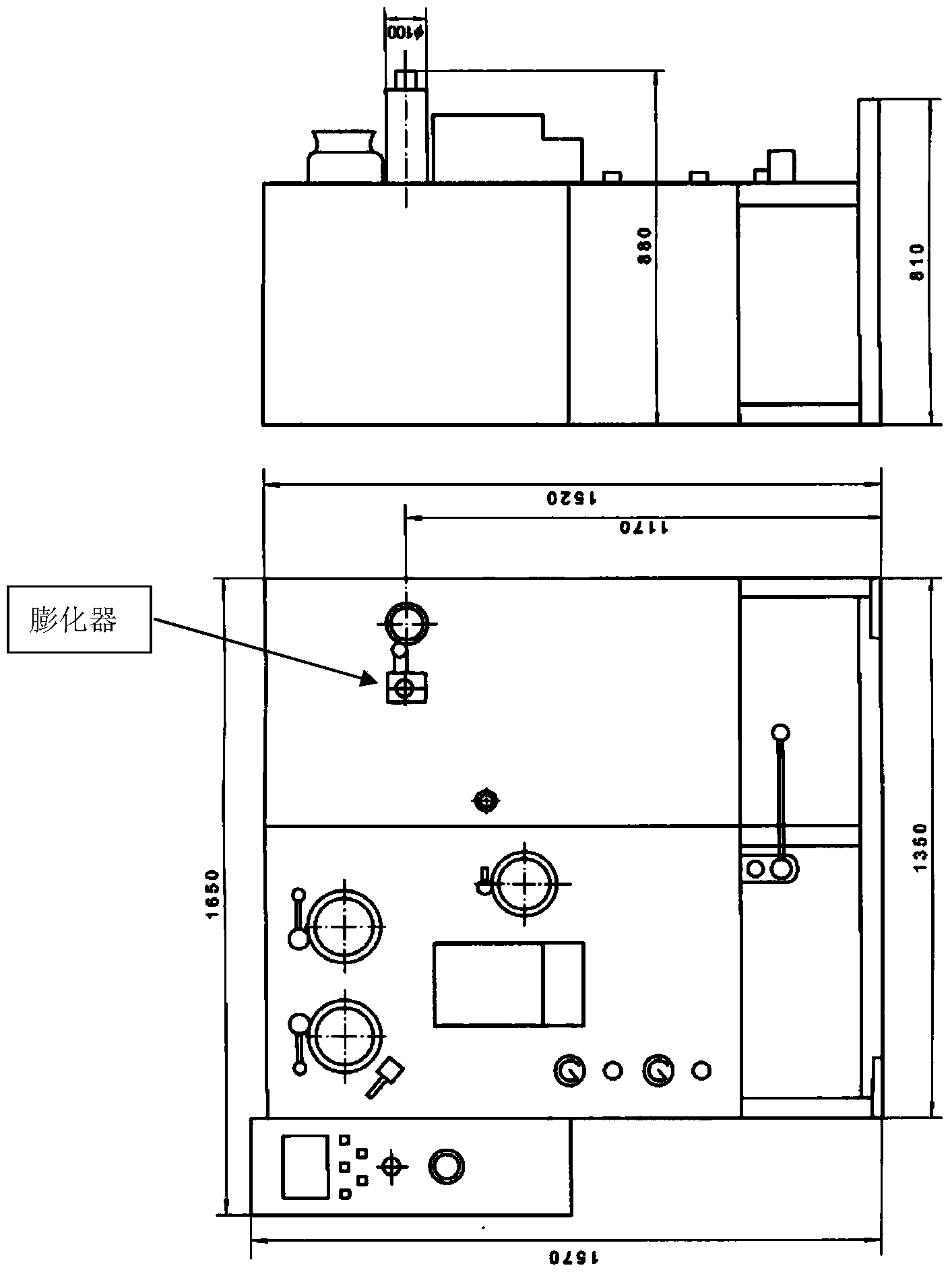

[0034] (3) Through transverse stretching, the continuous fiber bundles are dispersed and stretched in the transverse direction, so that the continuous fiber bundles are dispersed and thinned and widened, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com