Method for treating wear-resisting corrosion-proof dough pressing roll

A processing method and a surface pressing roller technology, applied in the field of mechanical parts processing, can solve the problems that affect the hygiene of noodles and human health, are not too easy to corrode and rust, and are not easy to clean after pressing, so as to facilitate carburizing treatment and improve hardness. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

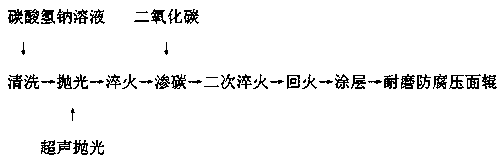

[0026] A treatment method for a wear-resistant and anti-corrosion pressing roller, comprising the following steps:

[0027] Place the forming pressing roll in a sodium bicarbonate solution with a concentration of 3% by mass, clean it ultrasonically for 20 minutes at a frequency of 27kHz, and a temperature of 45°C, take it out, and wash it with clean water to fully remove the stains on the surface of the pressing roll and improve The post-processing effect is to get the cleaned parts; then the cleaned parts are ultrasonically polished for 45 minutes, the frequency is 26kHz, the polishing liquid is nano-diamond polishing liquid, and the roughness is 0.1~0.2μm, which can achieve Fully polish to improve the smoothness of the pressing roller, which is convenient for post-processing and use, and the polished piece is obtained; then the polished piece is placed in a vacuum furnace, heated to 470°C at a speed of 2°C / min, kept for 30 minutes, and continued to heat to 760°C ℃, heat pres...

Embodiment 2

[0030] A treatment method for a wear-resistant and anti-corrosion pressing roller, comprising the following steps:

[0031] Place the forming pressing roller in a sodium bicarbonate solution with a mass percentage concentration of 3.5%, ultrasonically clean it for 25 minutes, the frequency is 28kHz, and the temperature is 50°C. Take it out and wash it with clean water to fully remove the stains on the surface of the pressing roller and improve The post-treatment effect is to get the cleaned parts; then the cleaned parts are ultrasonically polished for 50 minutes, the frequency is 27kHz, the polishing liquid is nano-diamond polishing liquid, and the roughness is 0.1~0.2μm, which can achieve Fully polish to improve the smoothness of the pressing roller, which is convenient for post-processing and use, and the polished piece is obtained; then the polished piece is placed in a vacuum furnace, heated to 490°C at a speed of 2.5°C / min, kept for 35min, and continued to heat to 790°C ℃...

Embodiment 3

[0034] A treatment method for a wear-resistant and anti-corrosion pressing roller, comprising the following steps:

[0035] Place the forming pressing roller in a sodium bicarbonate solution with a mass percentage concentration of 4%, ultrasonically clean it for 30 minutes, the frequency is 29kHz, and the temperature is 55°C, take it out, wash it with clean water, and fully remove the stains on the surface of the pressing roller to improve The post-treatment effect is to get the cleaned parts; then the cleaned parts are ultrasonically polished for 55 minutes, the frequency is 28kHz, the polishing liquid is nano-diamond polishing liquid, and the roughness is 0.1~0.2μm, which can achieve Fully polish, improve the smoothness of the pressing roller, facilitate post-processing and use, and get polished pieces; then put the polished pieces in a vacuum furnace, heat to 510°C at a speed of 3°C / min, keep warm for 40min, and continue to heat to 820°C ℃, keep it warm for 90min, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com