Steel plate shear wall

A steel plate shear wall and steel plate technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of low utilization rate of steel plates, and achieve the effects of improving utilization rate and economy, good seismic performance, and inhibiting stress concentration phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

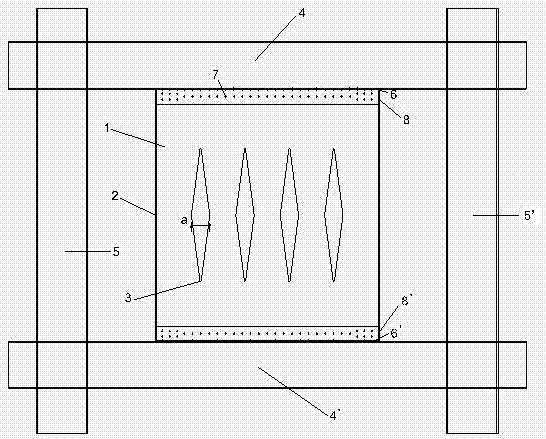

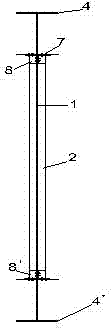

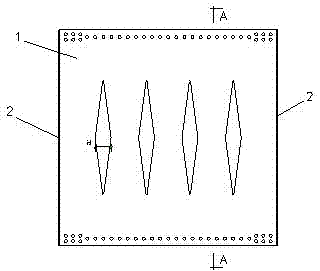

[0027] Such as Figure 1-5 The steel plate shear wall shown includes upper edge frame beam 4, lower edge frame beam 4', first frame column 5, second frame column 5', holed steel plate 1, upper end angle steel 6 and lower end angle steel 6', upper The edge frame beam 4, the lower edge frame beam 4', the first frame column 5, and the second frame column 5' form a frame structure, and the perforated steel plate 1, the upper end angle steel 6 and the lower end angle steel 6' are arranged in the frame structure, and the perforated steel plate The upper end of 1 is sequentially connected with the upper end angle steel 6 and the upper edge frame beam 5', and the lower end of the perforated steel plate 1 is sequentially connected with the lower end angle steel 6' and the lower edge frame beam 4'.

[0028] There are bolt holes 7 on the open steel plate ...

Embodiment 2

[0034] It is basically the same as that of Example 1, except that the left and right first stiffeners 2 have an I-shaped section, and the diamond-shaped hole 3 on the steel plate 1 is cut by plasma, and the diamond-shaped hole 3 is multi-layered.

Embodiment 3

[0036] It is basically the same as that of Embodiment 1, except that the left and right first stiffeners 2 have a rectangular cross-section, and the diamond-shaped hole 3 on the perforated steel plate 1 is water-cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com