Riverbed non-dam type hydroelectric generation system

A technology for power generation systems and riverbeds, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of limited utilization of water energy resources, high cost of tidal power plants, and inability to use large-scale use of water energy resources. The effect of high efficiency, wide application conditions and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

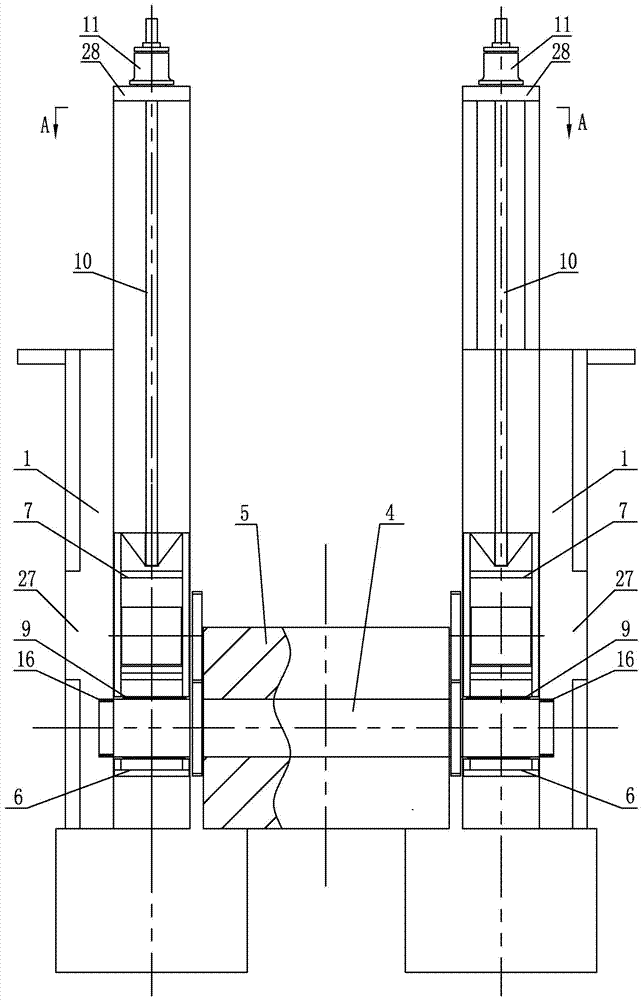

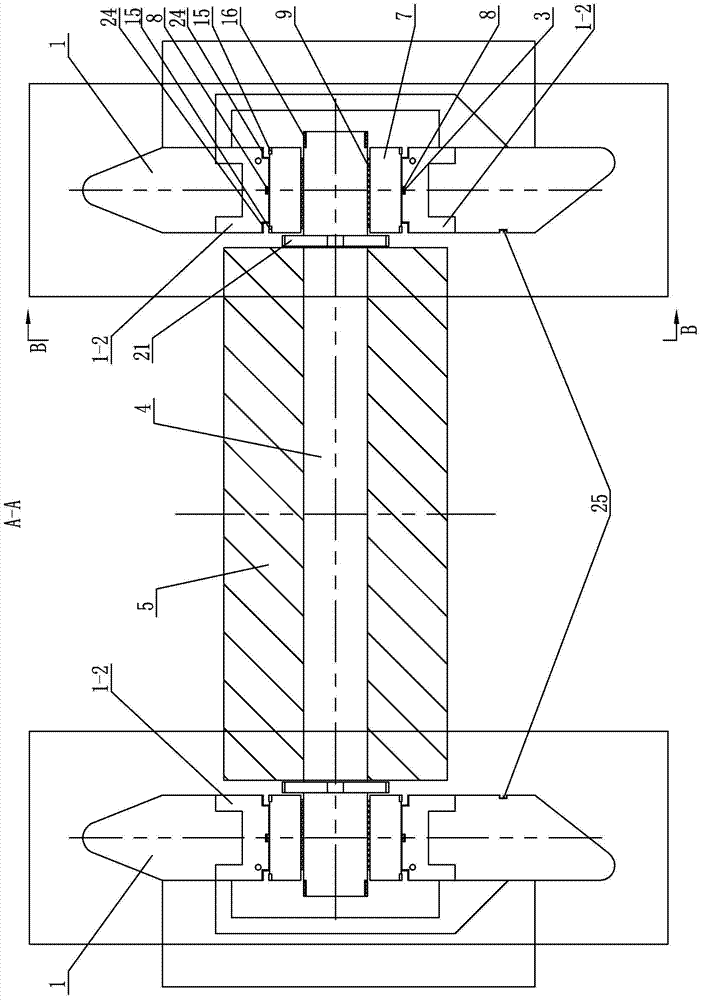

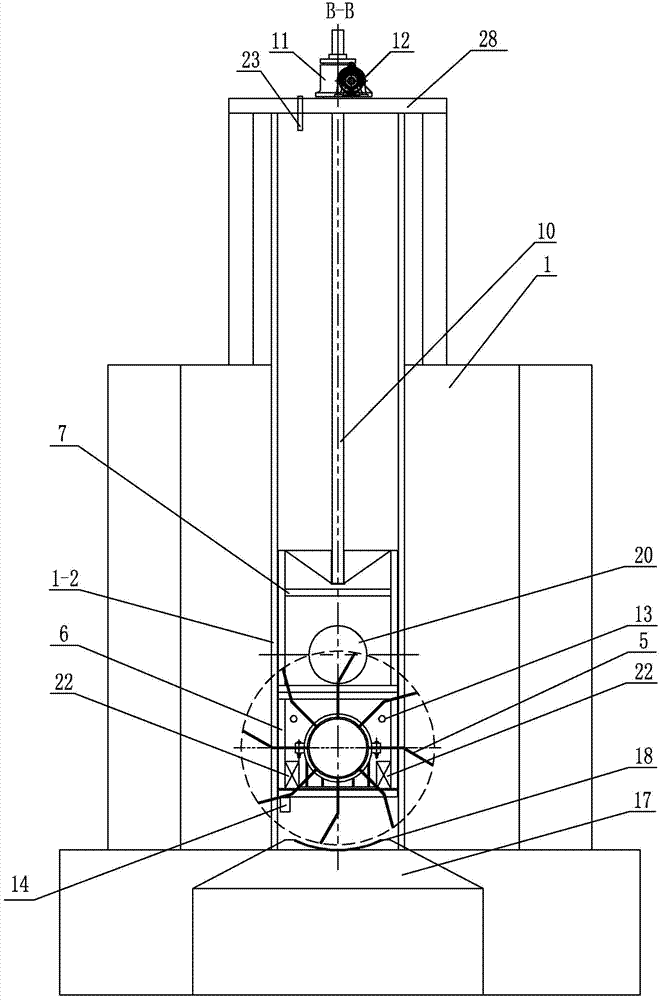

[0018] Specific implementation mode one: combine Figure 1-Figure 4 Illustrates that a river bed dam-free hydroelectric power generation system in this embodiment includes a water turbine, a guide body 17, a guide plate 18, two Π-shaped frames 1, two sets of bearing platforms 6, two sets of power generation platforms 7, two sets of generators 20. Two sets of speed increasing gear sets 21 and two sets of lifting mechanisms;

[0019] The two Π-shaped frames are reinforced concrete frames, and the two Π-shaped frames 1 are arranged facing each other. A set of bearing platforms 6, a set of power generation platforms 7, a set of generators 20, a set of The speed-increasing gear set 21 and a set of lifting mechanism; the bearing platform 6 is installed between the two columns 1-2 of the Π-shaped frame, and the water turbine includes a rotating shaft 4 and a plurality of bending blades 5, and each bending blade 5 is two sections type bending blade, the rotating shaft 4 is arranged h...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 and figure 2 To illustrate, the bearing bush 9 in this embodiment is an elastic metal-plastic bearing bush. This embodiment cancels the engine oil lubrication mechanism, avoiding the phenomenon of engine oil polluting the water body, and the allowable pressure of the elastic metal plastic bearing bush is controlled at 20Mpa / cm 2 Below, the allowable line speed is controlled below 20m / s, the maximum allowable PV value is controlled below 80Mpa·m / s, and the dry dynamic friction coefficient is 0.12-0.20. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination image 3 Note that the power generation system in this embodiment further includes two filter screens 22 , and the bottom of the two sets of bearing platforms 6 are respectively installed with filter screens 22 . Such setting prevents impurities from entering the bearing pad and affecting the operation of the rotating shaft. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com