Pretreatment device and pretreatment method for transformer oil

A pretreatment device and transformer oil technology, applied in the preparation of test samples, etc., can solve problems such as low efficiency, large nitrogen consumption, waste, etc., and achieve the effects of saving usage, reducing test costs, and quick preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

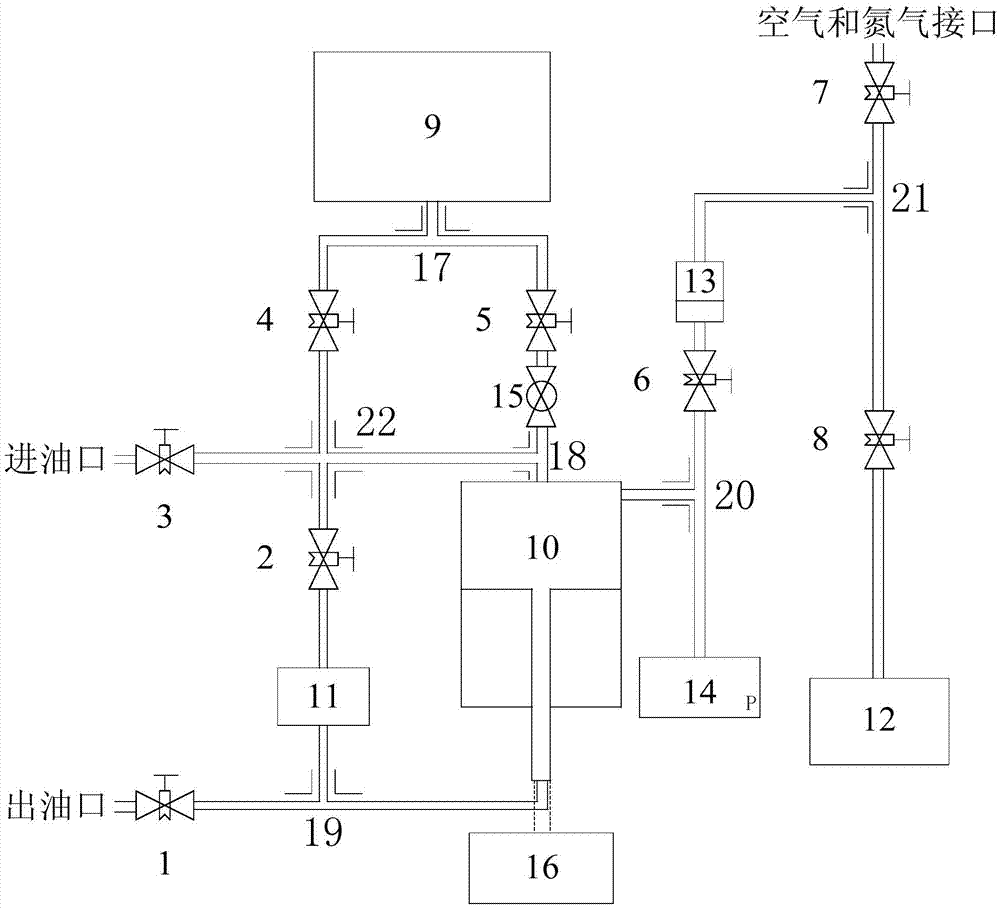

[0036] Such as figure 1 , the present invention provides a pretreatment device for transformer oil, said device includes a solenoid valve, a ball valve 15, an oil tank 9, an oil cylinder 10, a circulating pump 11, a vacuum pump 12, an oil-gas separation chamber 13, a pressure sensor 14, a stepping motor 16, Air and nitrogen interface, oil inlet and oil outlet; The oil inlet is connected with the oil tank 9, the oil cylinder 10 and the circulating pump 11 through a cross 22; the oil cylinder 10 is separated from the oil tank 9 and the oil and gas The chamber 13 is connected with the pressure sensor 14 respectively, and the ball valve 15 is arranged between the oil tank 9 and the oil cylinder 10; the piston of the oil cylinder 10 is fixedly connected with the stepping motor 16 through a mechanical device, and the bottom of the piston connected to the oil outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com