Database-based automobile instrument assembly flow line operation control method

A technology for assembly lines and automotive instruments, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as inability to accurately control assembly line processes, achieve reasonable software architecture design, improve operating efficiency, and program system resources Occupy small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

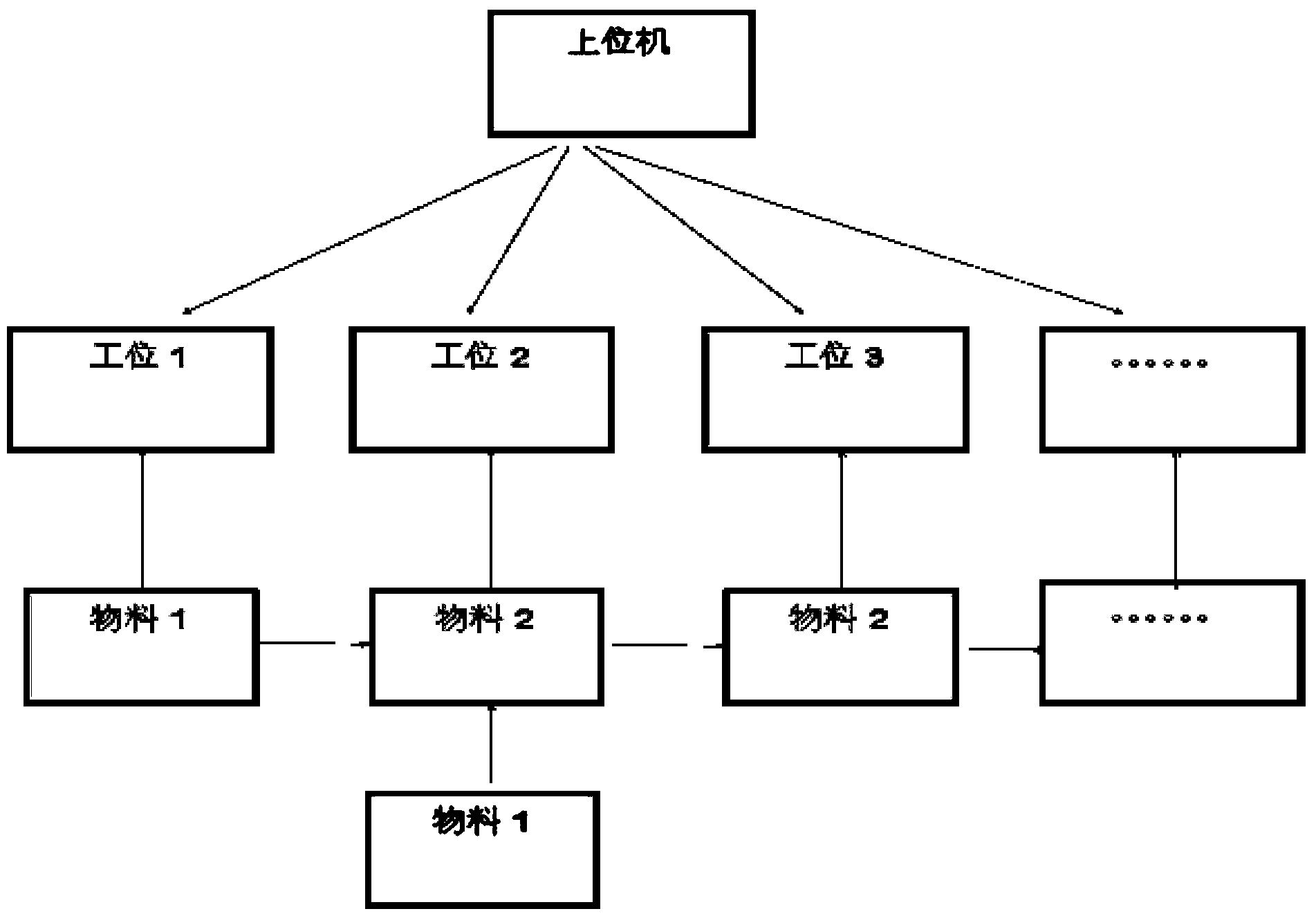

[0047] Specific embodiment one: a kind of database-based automobile instrument assembly line operation control method of this embodiment is realized according to the following steps:

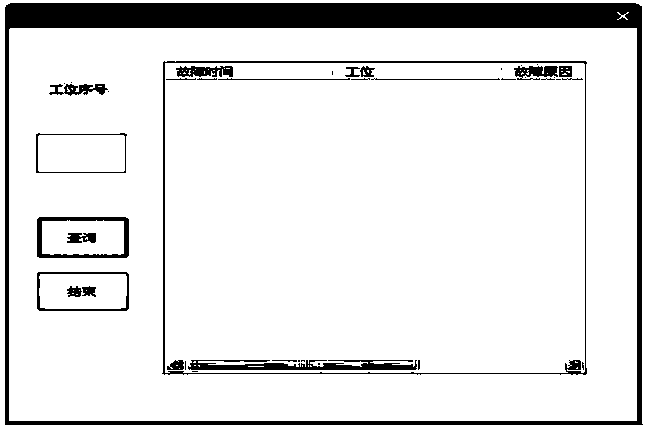

[0048] Step 1: Design the software interface of the upper computer: including the login interface and the production interface. The production interface includes five functions of query, statistics, troubleshooting, setting and fault information report, and displays the production quantity, qualified quantity and qualified rate in real time;

[0049] Step 2: Set up the database: based on the database, establish eight tables: user table, material table, station terminal material setting table, station terminal personnel setting table, work table, production history record table, fault history record table and real-time fault description table;

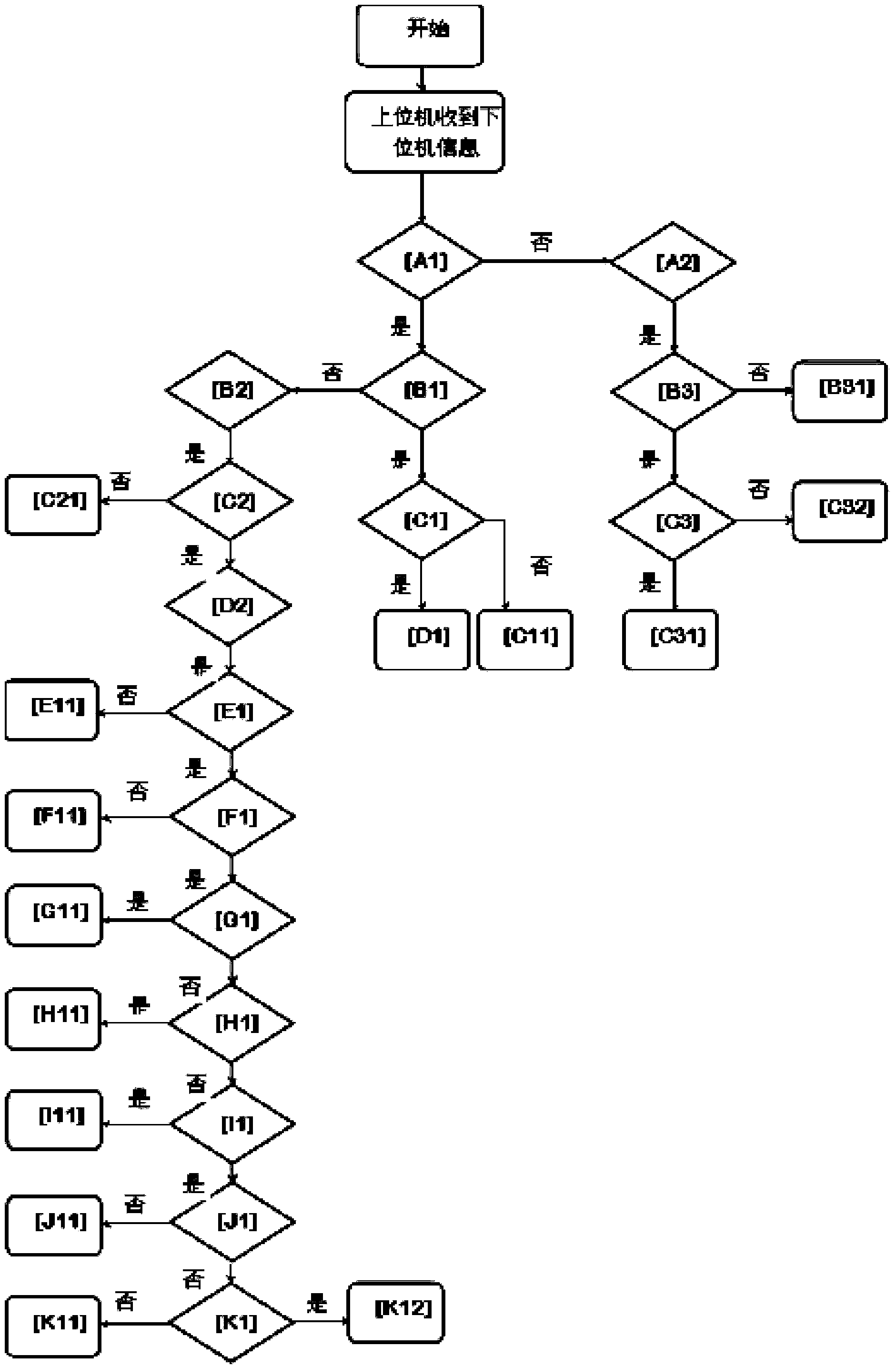

[0050] Step 3: The upper computer processes the information from the lower computer, and the specific process is as follows:

[0051] A1: The lower compute...

specific Embodiment approach 2

[0069] Embodiment 2: This embodiment differs from Embodiment 1 in that the user table described in step 2 is a data table that records all registered user names, user passwords, user barcodes, and user permissions. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0070] Embodiment 3: This embodiment differs from Embodiment 1 or 2 in that: the material table described in step 2 is a data table that records all registered material names and material barcodes. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com