Self-adjusting crimping pliers

A crimping pliers, self-adjusting technology, applied in circuit/collector parts, electrical components, circuits, etc., can solve the problems of no self-adjusting function, lack of reed space, lack of versatility, etc., to achieve beautiful appearance , Reduce the volume, the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

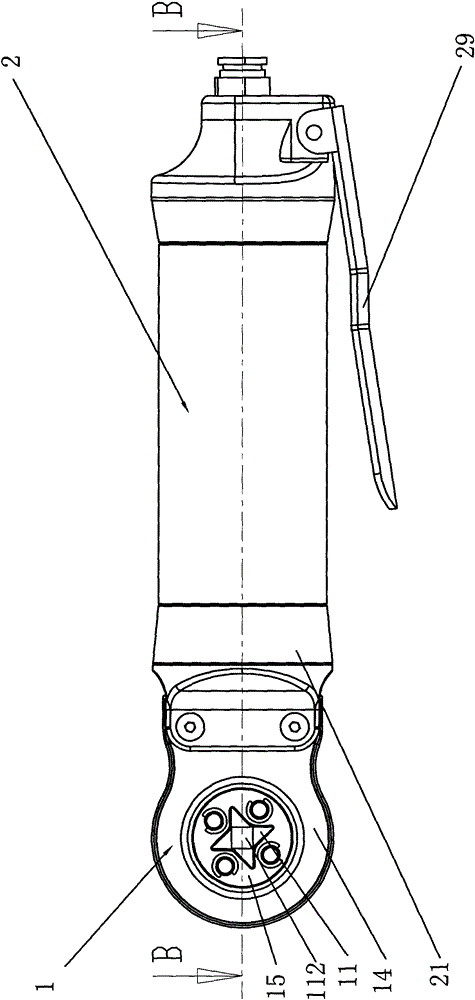

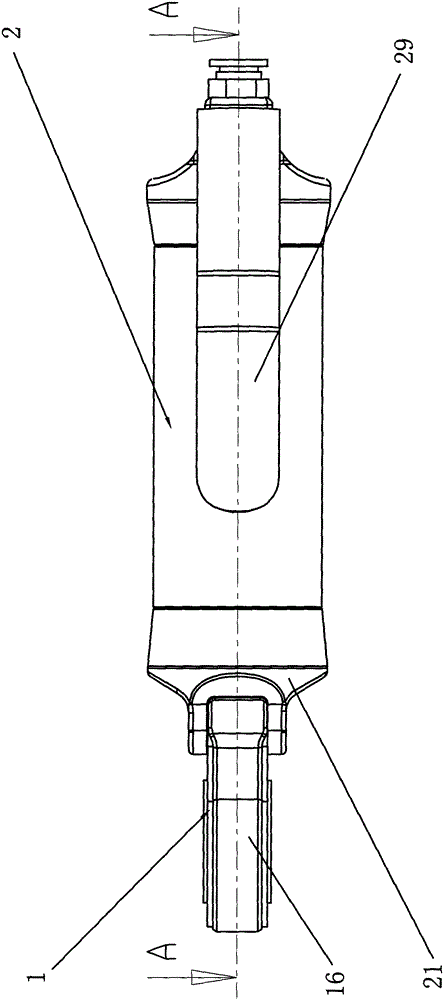

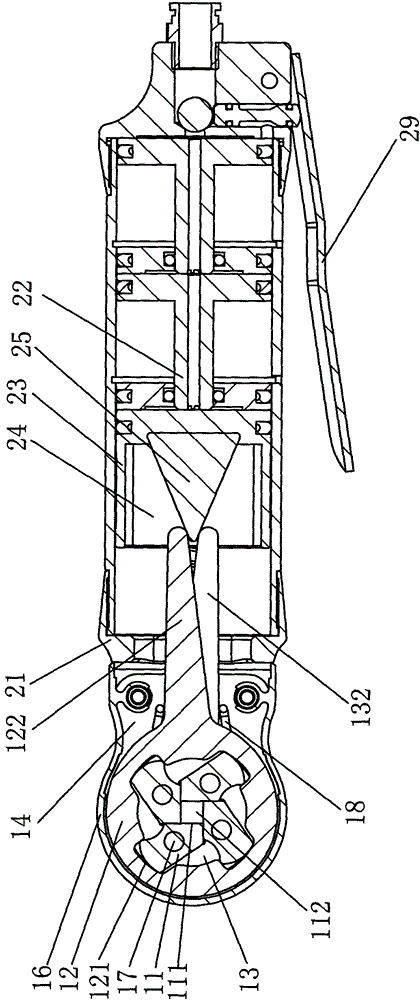

[0040] Such as Figure 1-6 As shown, the specific embodiment 1 of the present invention is a kind of pneumatic self-adjusting type wire crimping pliers, including a pliers head 1 and a double force cylinder 2, and the pliers head 1 includes a pressure tooth 11, a ring gear 12, a rotating plate 13, a support plate 14, Rotating cover 15, dust cover 16 and rotating shaft 17, four tooth grooves 121 are evenly formed on the inner side of ring gear 12, and a tooth arm 122 is formed on the outer side of ring gear 12 toward one end, and four pressure teeth 11 are arranged in ring gear 12. The tail part of 11 is arranged in the alveolar 121 to cooperate with the alveolar wall. The front end of the pressing tooth 11 is a crimping surface 111, and the crimping surfaces 111 surround each other to form a crimping port 112. The center of the pressing tooth 11 is hinged on the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com