A Differential Addition Atomization Dispersion Method and Device for Preparation of Nanofluid

A nanofluid and nanopowder technology, applied in chemical instruments and methods, mixing methods, dissolution, etc., can solve the problems of weakening nanofluids, strengthening heat and mass transfer and radiation absorption, reducing the stability of nanofluids, and reducing particle size. Effect of surface energy, improving dispersion efficiency and stability, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is a device and method for atomizing and dispersing nano-fluid differentially by using nozzle pressurized atomization.

[0030] The atomization and dispersion device is mainly composed of an atomization part and a liquid circulation part.

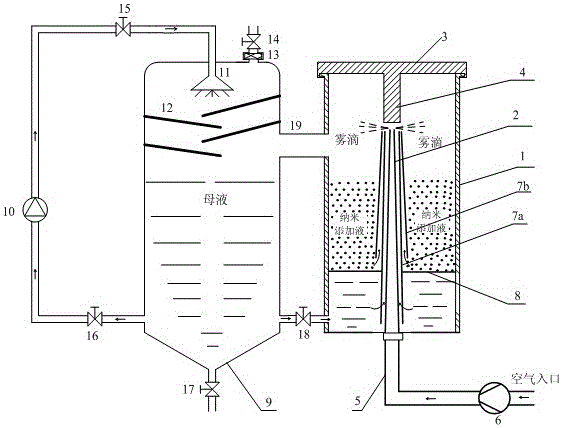

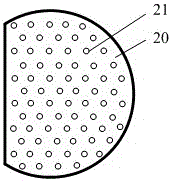

[0031] like figure 1 As shown, the atomization part consists of an atomization container (1), an atomization nozzle (2), a container cover (3), an atomization baffle (4), an air duct (5), a piston pump (6), a nozzle The inner jacket (7a), the outer jacket (7b), and the isolation plate (8) are composed. The atomization baffle (4) and the container cover (3) can be processed into a whole. The inner side of the atomizing nozzle is a trapezoidal cylindrical surface, and an air guide channel is formed inside, and is connected to one end of the external air duct (5) through the bottom of the atomizing container, and the other end of the air duct (5) is connected to the piston pump (6). The inner air guide channel of the ...

Embodiment 2

[0041] This embodiment is a nanofluid differential addition atomization dispersion device and method using ultrasonic atomization.

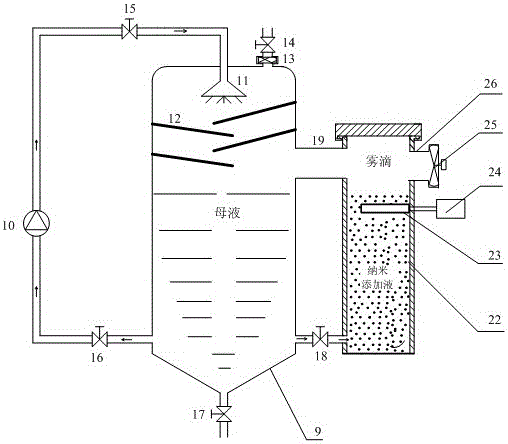

[0042] The device is composed of liquid circulation components and figure 1 The ones shown are exactly the same, and the only difference is the atomization components, which mainly include: ultrasonic atomization container (22), ultrasonic atomization sheet group (23), ultrasonic generating circuit (24), fan (25). The atomizing container (22) is connected with the liquid reservoir (9) of the liquid circulation part, and the ultrasonic atomizing sheet group (23) is fixed on the wall of the atomizing container at a certain height below the connecting pipe (19), so that the nanometer additive liquid in the container Just submerged the atomizing sheet group, the transducer (nickel or titanium high-frequency piezoelectric sheet) is packaged inside, and connected to the ultrasonic generating circuit (24). The tuyere (26) is set against the container w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com